ORLANDO, FL — April 29, 2025 Battcon, organized by the Consortium for Battery Innovation (CBI), is the industry’s benchmark event for real-world application training and the latest critical developments in stationary battery systems. Today, Battcon announced that the IEEE Power & Energy Society (PES) will be the technical co-sponsor for its 2025 event. This marks the first technical co-sponsorship between Battcon and the IEEE Power & Energy Society, expanding the conference’s global reach and technical impact.

Scheduled for Aug. 3–6, 2025, in Orlando, Florida, Battcon brings together engineers, operators, manufacturers and end users to address critical challenges in backup power systems for many different markets like data centers, energy storage systems, utilities, and telecommunications. With IEEE PES involvement, Battcon 2025 will be included on the IEEE Conference Search/Call for Papers website, and conference materials will be eligible for archival in IEEE Xplore®, expanding access to speaker research and technical findings across the global energy community.

“The involvement of IEEE PES as a technical co-sponsor enhances the already outstanding technical content at Battcon 2025,” said Dr. Matt Raiford, senior technical director of the Consortium for Battery Innovation. “Their role in co-publishing and archiving the conference’s peer-reviewed technical papers ensures that our speakers’ contributions are preserved and shared with a global network of power and energy professionals. This partnership strengthens the value of Battcon as a platform for advancing real-world battery applications in critical infrastructure.”

The IEEE Power & Energy Society, the world’s leading forum for electric power and energy innovation, has more than 42,000 members worldwide. Their participation furthers Battcon’s mission to deliver top-tier technical education and drive advancements across grid storage, telecom backup and data center UPS systems.

Battcon, organized by the Consortium for Battery Innovation (CBI), is where technical expertise meets real-world application. The 2025 event will feature expert-led sessions, pre- and post-conference workshops, an expanded expo, and targeted networking receptions connecting professionals across the stationary battery community. In Battcon’s uniquely independent exhibit hall, attendees can engage directly with leading manufacturers, suppliers and service providers. Learn more at www.battcon.com.

From a speech by Dr Carl Telford at the European Parliament in Brussels

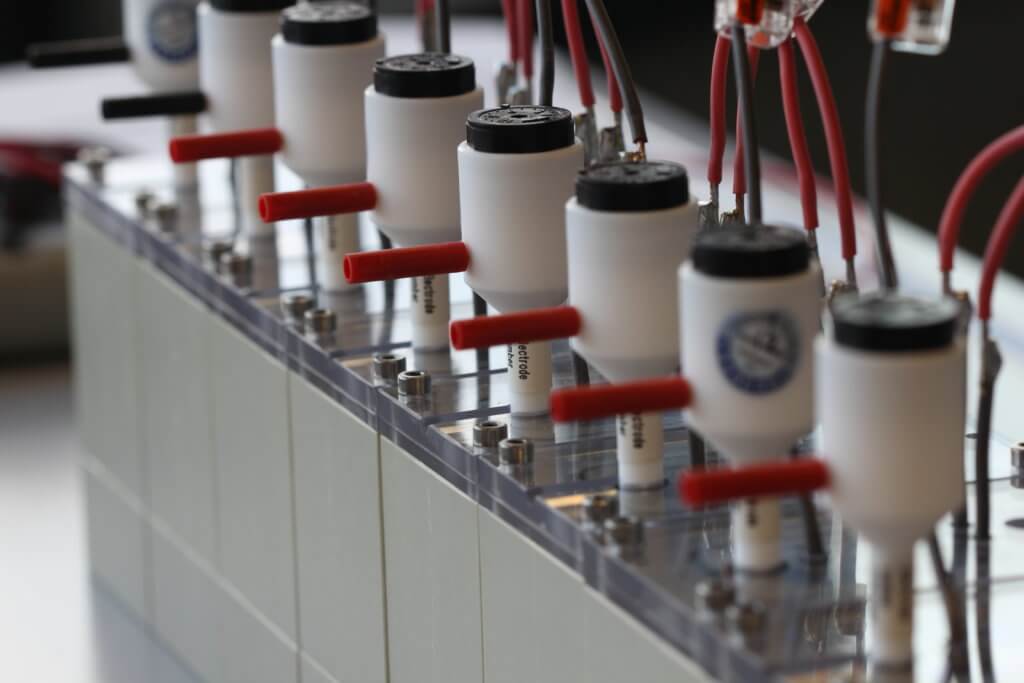

As the Consortium for Battery Innovation’s name implies, my work places me in the middle of European energy storage activity. I work with large battery companies, universities, and put exciting project together. CBI’s core research aims at improving the capabilities of advanced lead batteries – but we are also technology agnostic and are extending our research to include other battery chemistries. Not just lithium, but sodium, zinc, redox flow, and perhaps technologies that are hitherto unknown.

The key thing is, we recognise the role of all these technologies in enabling energy security, decarbonisation, and affordable energy provision.

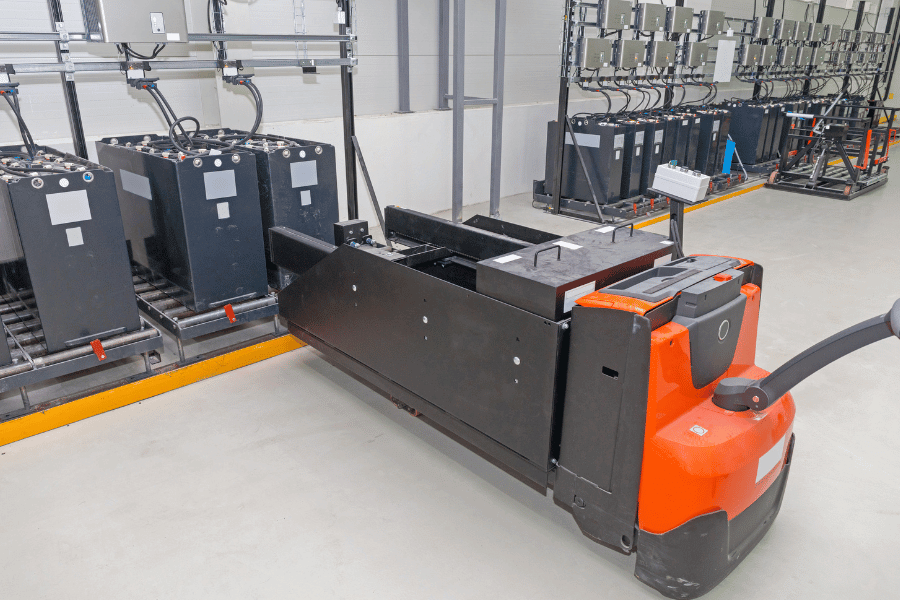

The European energy storage industry is already an impressive space. From Germany, to Portugal, Italy, Bulgaria and more – I have travelled and visited advanced lead battery manufacturing facilities across the continent. Combined, we have a pan-European multi-gigawatt production capability at our fingertips. Today. These batteries are used in a wide variety of mission-critical applications, not just car batteries but also renewable energy systems, backup power, peak shaving, nuclear power plant operation, and defence applications such as tanks or submarines. They are a critical to European security and a key piece in the jigsaw puzzle that is the Clean Industrial Deal and the Affordable Energy Action Plan.

I recently visited a European factory, and as part of a factory tour, I was shown a battery about the size of a large box. It was a metre high . A rather anonymous looking thing. But without this box, you could not operate a nuclear power plant safely. A big battery, with an even bigger responsibility.

In most of these factories, old batteries come in at one end, and new batteries come out the other end. The lead battery industry is a closed loop. This is not only a good thing from a circularity perspective, but also from cost and energy-security perspectives. These are batteries whose raw materials are all freely available in Europe, with zero reliance on expensive difficult-to-source materials.

A lot of the work I do relates to renewable energy and energy storage systems or ESS for short. The ESS market is growing rapidly. A recent report by KPMG noted that the European market for ESS will approach 200GWh-per-year by 2035, and lead batteries have the potential to supply an important chunk of this, around 10-15GWh-per-year. CBI recently visited the Isle of Eigg, off the Northwest coast of Scotland. This community relies on a microgrid with an advanced lead-battery storage system to provide affordable electricity. You see the same story across the world, from Africa to Antarctica. We make tough, cost-effective batteries for challenging environments.

Our industry also conducts cutting edge research, which doesn’t always fall under the spotlight. I’ve put together a microgrid project for Horizon Europe which features a battery that, when fully charged, becomes an electrolyser, producing hydrogen. You don’t run out of storage, you just transition to another energy vector. Electrons to gas. This technology – called a battery-electrolyser or battolyser – is a European invention, developed in the Netherlands and the UK.

Another project we co-founded is called Aftrak. It combines a small, low-cost electric tractor, a scalable solar microgrid, and a novel agricultural technique. The tractor enables African farmers to increase their yields, sell surplus crops, and lift themselves out of subsistence. It is electrical and economic empowerment. I have seen this project grow from an idea on a scrap of paper in a hotel in Malawi, to a government-funded project, to an international prize winner, to a startup company, in 3 years.

These exciting projects would not be possible without the brilliant University scientists, imaginative startups, and determined, practical and supportive lead-battery manufacturers we have at our disposal in Europe.

We must not take them for granted; there is much more we can do.

My message to decision-makers in Europe is this:

Thank you.

At Exide Technologies we operate 11 manufacturing and 3 recycling facilities sites across Europe, employing 5,000 people directly (and many more through our European supply chain). Headquartered in Paris, our manufacturing footprint is Spain, Portugal, Germany, Poland, Italy, The Netherlands and France.

Our business is energy storage; we make advanced batteries, using two essential and complementary technologies: lead and lithium.

Our products underpin many essential applications all of which are critical to a successful and growing economy – from batteries supporting hybrid and electric on road vehicles to batteries supplying energy to industrial vehicle’s and batteries vital back-up systems for data centres and hospitals.

We also make batteries for defence applications: from batteries supporting submarines, to specialist batteries for tanks and other military vehicles.

All made in Europe and recycled in Europe.

Europe needs an eco-system of different battery technologies for a wide variety of application in order to fulfil our own needs and in order to compete globally. We are technology agnostic, which is key to supporting battery technologies to innovate and develop here.

One of Europe’s greatest strengths is that we promote stability and predictability on the world stage. And it is just as important that we create the same conditions for companies operating in Europe.

As EU President Ms Von der Leyen put it: “In today's world, maintaining Europe as an economic powerhouse is a matter of collective security.”

Our commitment is to make advanced batteries in Europe, and recycle them in Europe.

Exide Technologies has a proud track record of manufacturing and recycling lead batteries in a closed loop – ALL lead batteries collected in Europe are recycled and re-used to make new batteries. Now we’re applying that knowledge and skill to recycling lithium batteries at our facility in Spain, helping ensure that Europe can recycle and re-use critical raw materials.

And we’re committed to decarbonisation and the transition to a ‘clean’ industry – let me give you one example, in Portugal, we operate state-of-the-art solar installations, powering our manufacturing and our recycling facility with advanced lead battery energy storage.

We have reduced carbon emissions at these sites by 20% and more and more companies will I hope follow this model in the years ahead.

Our business is strategically autonomous – our raw materials (most of them recycled) come from Europe and we distribute our batteries in Europe but also serve markets in Asia, Africa and the Middle East.

Above all, we have a highly adaptable and capable workforce. We must keep their skills here in Europe.

And - of course - we comply with a whole raft of existing European and domestic legislative and regulatory requirements to protect employees, the environment and the community.

So our message to policy makers is straightforward. Please do allow us to continue to operate, to innovate, to compete. We don’t seek special assistance. But we do seek a level playing field. We all want to see costs reduced, be they energy or other compliance requirements.

Please don’t increase the regulatory burden. And where regulatory measures are necessary make sure they are proportionate and risk-based.

But we also see a couple of regulatory items that need to be resolved. In the past, we have seen efforts to authorise lead under REACH, essentially sending a signal that lead is banned and acting as a disincentive to invest. This approach is highly counterproductive and has to stop. We hope that the REACH revision later this year will consider that.

I’m sorry to say that batteries are a typical example for unnecessary burden and threat from overlapping legislation. Currently we have three regimes reviewing and restricting the use of substances in batteries.

The quite outdated review scheme of substance bans and exemptions under the ELV Directive from 2000.

The evaluation, classification, restriction and authorization scheme under REACH. Also a legislation that is 15 years old and the new kid on the block, the review and restriction scheme mandated by Article 6 of the EU Battery Regulation.

It won’t surprise you that our industry is not so happy with the three regimes all heading for the same target – making products safer and more sustainable. It should also not surprise you that battery industry wants to have the battery substances regulated under one piece of legislation – preferably the Battery Regulation – only.

Finally, I would like to mention the metals action plan, published earlier today, as one example where we need policy makers to think more broadly about Europe’s industrial needs. It focuses on a few key metals – which are important, like steel - but I fails to include the importance of a much wider group of metals like lead which are essential to our competitiveness and our autonomy. This is the kind of joined up thinking we need, and I’d urge the Commission to think about all the metals necessary to boost growth, to innovate and to defend ourselves, both economically and militarily.

As a company we do not stand still. We invest and we innovate. That is why the Clean Industrial Deal must be on the side of industry so that we can compete, grow and continue to make it in Europe.

The former European Central Bank President Mario Draghi put his finger on Europe’s problem in his report on EU competitiveness.

“For Europe to remain free,” he wrote, “we must be more independent. We must have more secure supply chains for critical raw materials and technologies. We must increase production capacity at home in strategic sectors. And we must expand our industrial capacity.”

His comments were prescient given the new political dynamic arising from the change of political direction in the United States, and the requirement for Europe to ‘stand on its own two feet.’

The clean industrial deal (CID) presented by the European Commission sets the right tone and is a step in the right direction. However, if European industry is going to be free to innovate, invest and build on our many manufacturing strengths. Butwe need the European Commission to deliver on these promises – and quickly.

While we applaud the clear ambition to be a continent of industrial innovation and production. And we want more streamlines and proportionate – or simplified - regulation. But the warm words must result in concrete and clear actions at every level of decision making.

Europe is indeed facing a watershed moment, as the President of the European Commission said when launching this initiative. In more ways than one Europe is on a war footing. In the battle for competitiveness in a world that no longer boasts a level playing field for trade. In the battle for innovation and the ability to harness the benefits of new technology and AI. And in the battle for democracy and self-determination – building a defence capability to match any potential threat to our borders.

The one thing missing from the announcements about the clean industrial deal is the importance of valuing the core industries we rely on today and which will act as the foundation for any future industrial growth and competitiveness.

There are many industrial success stories in Europe – which may seem surprising given the level of regulation and bureaucratic uncertainty businesses have faced in recent years.

We need industries like ours – producing advanced lead batteries used in everything from cars and trucks to tanks and submarines– to continue to grow and innovate as part of an EU battery eco-system. Europe is home to some of the most advanced battery manufacturing and recycling capabilities in the world. You just may not have heard about them.

And we are probably the best example of the circular economy in action. All the lead batteries collected at the end of their life in Europe are fully recycled and re-used in making new batteries.

So our plea to decision-makers is simple. Get behind the industries of today so they can flourish tomorrow. Let us get on with what we do best. Ensure regulation is proportionate, predictable, and consistent across policy areas. Support innovation and investment by ensuring we have a stable legislative and regulatory platform on which to build. And create the best possible conditions for us to continue to invest in people and skills.

Our technology will be an important part of the jigsaw helping achieve greater electrification and decarbonisation. Value the industries we already have in Europe, tear down the barriers and let them flourish.

Europe is the largest exporter of manufactured goods and services. Our strengths outweigh the weaknesses. Businesses value stability and certainty. In these tumultuous times they could be our greatest asset.

Watch the video update about this project here:

DURHAM, N.C. – Jan 31, 2024 – As part of our continued efforts to support advanced lead battery uptake for energy storage applications, the Consortium for Battery Innovation (CBI) has joined as Teaming Partner of the U.S. National Consortium for the Advancement of Long Duration Energy Storage (LDES) Technologies.

Launched in January 2024, this three-year initiative funded by the U.S. Department of Energy (DOE) proposes an independent forum to bring together stakeholders across the LDES ecosystem. The main goal is to promote collaborations to develop and implement strategies necessary to achieve the commercialization of LDES technology within the next ten years.

The power sector is responsible for one third of emissions in the U.S. according to estimates by the U.S. DOE. The transition to carbon-free renewable sources must address the intermittent nature of wind and sun, and LDES is a key option to provide the needed flexibility and reliability to the grid. Batteries are among the most viable storage technologies for shifting excess power produced at one point in a day to another point within the same day (inter-day LDES), or to multiple days in the future (multi-day / week LDES).

The LDES National Consortium is led by Sandia National Laboratories with the support of five other National Laboratories - Argonne, Idaho, National Renewable Energy, Oak Ridge, and Pacific Northwest. The partnership already counts with over 130 Teaming Partners who are working together in Tiger Teams to identify and evaluate challenges in specific focus areas impacting LDES. One key aspect of the Consortium is its Diversity, Equity, Inclusion, and Accessibility Strategy, leveraging community engagement to ensure that LDES technology rollout brings concrete benefits to underserved communities.

CBI’s Research & Innovation Manager, Dr Alyssa McQuilling, and CBI’s Technical Director, Dr Matthew Raiford, are actively involved in eight of the sixteen Tiger Teams, namely: Technology Development, Evaluation and Testing; Demonstrations and Deployments; Investor Confidence and Finance; Use Case Development; Workforce Development; Reliability and Resilience; Economics and Valuation; Supply Chain and Manufacturing Efficiencies.

"The extensive infrastructure and domestic circularity offer an incredible opportunity for the industry to learn how we can adapt lead battery technology to the needs of LDES."

Dr Matthew Raiford, Technical Director at the Consortium for Battery Innovation

Our experts point out that advanced lead batteries are particularly well suited to inter-day LDES applications. They also see the potential around hybrid long duration systems, combining advanced lead batteries with another technology such as flow batteries to cover both short and long duration response. Dr Alyssa McQuilling said: “There is a lot of opportunity for lead batteries as a part of the solution for long duration storage, and the growth of the industry will require all kinds of technologies to meet the needs of utilities and other consumers.”

“I’m excited by the scale of the project, ranging from technology and use cases to markets and economics all the way to supply chain and workforce development. We are covering every challenge facing long-duration storage and the efforts of this consortium will benefit the energy storage industry beyond just its long duration applications.”

Dr Matthew Raiford said: “The US lead battery industry is uniquely poised to collaborate in this effort. The extensive infrastructure and domestic circularity offer an incredible opportunity for the industry to learn how we can adapt lead battery technology to the needs of LDES. The ongoing efforts from the US DOE LDES consortium will be a hotbed to learn and bring this learning into our industry.”

###

Notes to editors

About the Consortium for Battery Innovation

The Consortium for Battery Innovation is the world’s only global pre-competitive research organization funding research into lead batteries for energy storage, motive and automotive applications. For more than 25 years, with its global membership of battery manufacturers, industry suppliers, research institutes and universities, CBI has delivered cutting-edge research pushing the boundaries of innovation in lead battery technology, setting the standard for advanced lead batteries and the next generation of energy storage. For more information, visit our website: www.batteryinnovation.org

Dr Alyssa McQuilling, Research & Innovation Manager, and Dr Matthew Raiford, Technical Director, are available for interview. For more information, please contact CBI’s media contact: Nicola Filizola, nicola.filizola@batteryinnovation.org

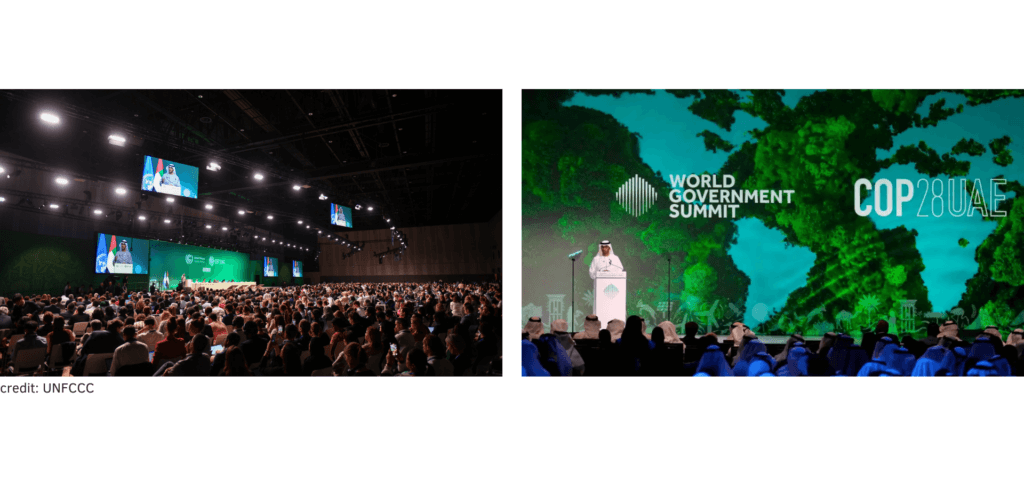

The COP28 conference marked an important moment in the global conversation about energy storage and batteries. While signalling the need to move away from fossil fuels, it emphasised the potential of energy storage to shape a sustainable energy future significantly.

The 28th Conference of the Parties (COP28) to the United Nations Framework Convention on Climate Change was held in Dubai from 30th November to 12th December. The conference brought together global leaders, experts, and stakeholders to address the pressing issue of climate change. The theme of COP28 was "Building a Resilient Future," focusing on accelerating global action to limit global warming to 1.5 degrees Celsius above pre-industrial levels.

Despite the scepticism that preceded the conference, particularly surrounding the host nation, Dubai, a major oil producer, COP28 emerged as a revolutionary climate change summit. For the first time in 28 years, fossil fuels were formally recognised as the primary driver of climate change. This acknowledgement, a significant shift from the previous COPs, marked a turning point in the international community’s approach to climate change. It challenged the long-held narrative that fossil fuels were necessary for the energy mix and laid the foundation for a faster transition to a low-carbon economy. This formal recognition of fossil fuels’ role in climate change was not just a symbolic gesture but led to a series of bold decisions and commitments to accelerate the global transition to clean energy sources. Over 100 countries pledged to phase-out coal power by 2030, which is a huge milestone in decarbonising the energy sector.

Energy storage for green transition

COP28 provided an opportunity for stakeholders to discuss the complexities of energy storage technologies and their potential to contribute to a more sustainable energy future. The discussions focused on integrating renewable energy sources, enhancing the stability of power grids, and addressing the issue of energy poverty. COP28 witnessed several notable developments related to energy storage, including the launch of the Supercharging Battery Storage Initiative and the Multilateral Consortium for Battery Storage.

Member governments of the Clean Energy Ministerial (CEM), including the European Commission, Australia, Canada, and the United States, announced the launch of the Supercharging Battery Storage Initiative in Dubai. This initiative aims to increase the capacity of battery storage in the power grid while ensuring a transparent, resilient, and sustainable energy system. It is focused on reducing technology costs, as batteries play a crucial role in creating a flexible and reliable energy system. Through this initiative, member governments of the CEM are committed to a cleaner and more accessible energy future. “Battery storage will be the backbone of the green transition with an essential role in decarbonising transport and energy. It will enable a truly decentralised and integrated energy system based on efficient use and renewable generation,” said Maroš Šefčovič, Vice President of the European Commission.

Bridging the energy gap

The Global Leadership Council announced the formation of the Battery Energy Storage Systems (BESS) Consortium, with participation from 11 African countries. The consortium has pledged to deploy a minimum of 5GW of battery storage systems in Africa by 2030. The initiative seeks to tackle energy poverty and improve access to reliable electricity in low- and middle-income nations on the continent. Dr. Rajiv J. Shah, the President of The Rockefeller Foundation and Co-chair of the GLC, highlighted the need for transformative initiatives. He stated that "Without sufficient storage capacity, countries will be unable to add renewable energy to their grids at the scale needed to reduce emissions and create economic opportunity. The BESS Consortium is an example of the sort of big, bold action required to break down the barriers that are preventing people and communities from joining the ongoing climate transformations."

As part of the COP28 agreements on energy storage, the United States and partner countries of the Net Zero World initiative have announced significant progress in building clean and secure energy systems in emerging economies. This includes helping Ukraine deploy distributed renewable energy and storage systems for critical infrastructure. Participants of COP28 have also called for increased investment in research and development for energy storage technologies. The aim is to accelerate innovation, improve performance, and reduce costs, making energy storage more accessible and cost-effective.

Advancing a cleaner future

The decisions and commitments made at COP28 are a step forward in the global effort to combat climate change. By acknowledging the role of fossil fuels in climate change and committing to a rapid transition towards a low-carbon economy, COP28 has set a new course for the international community.

Moreover, the conference marked an important moment in the global conversation about energy storage. COP28 emphasised the potential of energy storage to significantly shape a sustainable energy future. Initiatives such as the Supercharging Battery Storage Initiative, BESS Consortium, and Net Zero World all point in one direction, addressing energy poverty, promoting sustainability, and achieving clean energy goals. To achieve this, we need all battery chemistries.

The conference's outcomes indicate a renewed commitment to accelerating the development and deployment of these technologies. As energy storage becomes more widespread and cost-effective, it will play a critical role in addressing climate change, ensuring energy access, and creating a more resilient and sustainable energy system.

The Consortium for Battery Innovation is actively involved in the rollout of advanced lead battery energy storage systems to contribute to global climate goals. In two ongoing energy storage projects, LoCEL-H2 and Aftrak, we are helping develop BESS combined with solar microgrids to provide a sustainable, reliable, low-cost energy system for remote communities. These projects also demonstrate how energy storage solutions are key to achieving a just transition, helping to increase food access, health outcomes and gender equality. With more energy storage projects underway, CBI will continue to support sustainable development for a climate-resilient future.

Battcon 2024 Miami, Florida, May 14-17

The Consortium for Battery Innovation has been appointed to manage the prestigious Battcon energy storage conference in the United States.

Battcon 2024 takes place in Miami, Florida, between May 14-17 at the Hyatt Regency Miami, with pre-conference workshops taking place on Tuesday May 14 followed by the full conference and trade show.

Battcon is an annual stationary storage battery conference showcasing developments in all battery chemistries which has been held in Florida for more than 25 years. The event, which attracts more than 400 delegates plus exhibitors, acts as a professional development and networking opportunity for the design, selection, and application of stationary, utility and energy storage battery systems.

CBI has issued a call for papers inviting speakers to submit abstracts on potential topics demonstrating new technical enhancements for all battery chemistries for the 2024 event. The conference is an opportunity for manufacturers and users to review the latest trends in stationary storage, including data-centers, telecoms, utility and energy storage applications.

View details and submit your abstract at www.battcon.com. Abstracts can be submitted directly by email to events@battcon.com

The Consortium for Battery Innovation is a global battery research group developing and promoting batteries and battery energy storage solutions.

CBI Director Dr Alistair Davidson described Battcon as a highly-respected industry event adding that CBI would continue to ensure the technical program and exhibition maintained its reputation for excellence.

He said: “We are committed to maintaining this important industry event and ensuring that Battcon continues to develop and grow alongside the energy storage industry. The conference is a significant professional development and educational opportunity supporting all battery technologies and chemistries. We have extensive experience managing technical events and given the exciting opportunities for stationary storage across many applications this conference will remain at the forefront of the green energy transition.”

Curtis Ashton, chair of the eleven-member Battcon technical committee, said: “Battcon is a popular, user-focused conference and as a technical committee we were keen that an organisation committed to battery energy storage should take on its management and future development. The committee felt CBI would be the best option. Its expertise and enthusiasm means that we can look to the event’s continued growth and focus on the rapidly evolving stationary battery industry.”

NEWS RELEASE - 21 November 2023

The ELBC battery innovation conference has issued a call for papers ahead of the event which takes place in Milan, between September 16-19.

Jointly organised by the International Lead Association and Consortium for Battery Innovation, the event’s technical committee is seeking abstracts on all aspects of lead battery technology with a specific focus on:

Dr Alistair Davidson, Director of the Consortium for Battery Innovation, said: “This is always a much-anticipated event for the lead and lead battery industries and we’re looking for high quality submissions that showcase recent innovations and all the latest lead battery research.”

Abstracts can be submitted online by visiting www.elbcexpo.org

More than 1000 attendees are expected at the event in Milan which includes an expo with up to 140 exhibitors from across the lead battery value chain.

About the Consortium for Battery Innovation (CBI)

For more than 25 years, CBI has delivered cutting-edge research taking lead batteries to a new level for energy storage and automotive applications. With an expert panel made up of the world’s leading battery manufacturers and research specialists, CBI is setting the standard for advanced lead batteries and the next generation of energy storage.

The Consortium for Battery Innovation's impactful presence at European Commission’s SET Plans Conference

In the ever-evolving landscape of energy storage, the Consortium for Battery Innovation (CBI) stands at the forefront, driving advancements in battery technology. At the recent SET Plans Conference in Viladecans, the CBI had a strong presence with its Senior External Affairs Manager, Nicola Filizola, showcasing the consortium's commitment to fostering collaboration and innovation within the energy transition landscape.

The revamped SET Plans to address energy policy

The European Strategic Energy Technology (SET) Plan was established in 2007 and since the creation of the energy union in 2015, it became one of the main instruments of the energy union’s 5th pillar on research, innovation, and competitiveness.

During the conference, the European Commission confirmed its commitment to reinforcing the SET Plan, and its acknowledgement of the key role that the initiative will play in delivering the European Green Deal, REPowerEU and the Green Deal Industrial Plan, with a particular emphasis on the Net Zero Industry Act. This will help to accelerate the clean energy transition, increase the EU’s competitiveness, and ultimately deliver the EU’s ambitious climate and energy objectives.

Boosting European competitiveness and technology sovereignty

The EU is a frontrunner in the deployment of sustainable energy solutions and in clean energy research and innovation. However, this leadership is not matched by an equally strong position in the manufacturing of net-zero technologies.

To strengthen Europe’s technological and industrial sovereignty, the European Commission has proposed the Green Deal Industrial Plan, which includes the Net-Zero Industry Act for increasing the EU manufacturing capacity of net-zero technologies, and the Critical Raw Materials Act for securing the supply of critical raw materials. The revised SET Plan will help convert innovations into marketable solutions that can be produced and scaled up in the EU.

Advancing battery technologies

The SET Plans Conference served as a global platform for discussing Sustainable Energy Technology Plans, bringing together experts, policymakers, and industry leaders to deliberate on the future of energy technologies. The CBI consortium's presence was crucial in highlighting the pivotal role that advanced lead battery technologies play in achieving sustainable energy goals.

As the battery industry continues to play a pivotal role in the global transition to clean energy, the CBI's active participation in conferences of this nature reinforces its position as a driving force in shaping the future of energy storage.

For more information on how to develop and reinforce the Brussels footprint for the advanced lead battery ecosystem, feel free to contact our Senior External Affairs Manager at nicolafilizola@batteryinnovation.org

Europe's commitment to renewable energy in the face of climate change

Climate change is happening right before our eyes and presenting new challenges for the world. European communities are grappling with increasingly frequent and intense extreme weather events that have profound impacts and demand our attention. The consequences are severe, from urban areas transformed into fiery landscapes during sweltering heat to towns inundated by floods.

The root cause of the climate crisis is our heavy reliance on fossil fuels. Burning these fuels releases greenhouse gases into the atmosphere, trapping heat and warming the planet. This disturbs the delicate balance of our climate system and intensifies the occurrence of extreme weather events. To face this crisis, we need to move towards a cleaner future with renewable energy sources such as solar and wind power. In addition to reducing our dependence on fossil fuels, renewable energy is essential for strengthening community resilience. This aligns with the European Union’s Green Deal, which outlines a comprehensive set of policies aimed to achieve a carbon-neutral economy by 2050.

European summer of extremes

This summer, Europe experienced a series of record heatwaves and devastating wildfires that have swept across the continent. The European Forest Fire Information System reports that up to 41% of the area burned in the EU is in Natura 2000 protected sites. In 2023 alone, wildfires have released more than 20 million tonnes of carbon dioxide into the atmosphere, exceeding the European average over the last two decades.

The Mediterranean region was hit hardest by this year's heat waves. The streets in Greece's ancient port town of Gytheio shimmered as temperatures climbed to an astonishing 46.4 degrees Celsius, setting a new record since record-keeping began in 2006. Life stood still in the sweltering heat, and the streets remained deserted. The heatwave also triggered a wave of wildfires that ravaged the countryside. Nearly 20,000 tourists abandoned Rhodes hotels due to the threat of wildfires, marking the largest evacuation of its kind in the country's history. The intensity of the heatwave caused widespread power outages and plunged towns into darkness. Hospitals struggled to maintain patient care, and businesses were forced to shut their doors.

In May 2023, Italy found itself in the grip of unforgiving weather. The tranquil rivers of Tuscany turned into raging torrents that surged through towns and villages, leaving destruction in their wake. Homes vanished beneath the rising waters, and critical infrastructure crumbled under the weight of the deluge. The downpours lasted 80 hours of relentless rainfall over six days, causing flooding and infrastructure collapse, leaving the affected areas in darkness. Over 20,000 citizens were forced to evacuate and seek refuge in temporary shelters such as schools, sports halls, and gyms.

Not only floods but also severe storms with strong winds are becoming a pressing concern in Europe. This year, Norway faced several relentless storms marked by a historic amount of rainfall. The Norwegian meteorological institute reported extremely heavy rainfall in parts of Norway, marking the strongest in the last 25 years. As winds and heavy rain swept across the region, trees were uprooted, flights faced delays, ferries stopped running, and power lines scummed to disruption. In cities like Oslo, people were urged to work from home. Meanwhile, in the small village of Bagn, nested in the heart of a valley surrounded by forests, landslides wreaked havoc, severing its residents from the outside world.

Researchers at Newcastle University predict extreme weather events will become more frequent due to the climate crisis. "Alongside drastically cutting emissions, countries must build more resilient infrastructure," the researchers said.

Renewable energy and climate resilience

In the face of a changing climate, Europe is at a crossroads. Floods, wildfires, and storms dominate the headlines. As extreme weather events become more frequent, the transition to renewable energy is necessary. The European Union recognises this need and has adopted bold initiatives such as the European Green Deal, a comprehensive roadmap to reach climate neutrality by 2050. Central to this strategy is the Fit for 55 initiative, which aims to reduce greenhouse gas emissions by at least 55% by 2030. Additionally, the RePower EU plan aims to decrease the dependency of the European Union on Russian fossil fuels and promote green energy.

These initiatives address the challenges highlighted by the extreme weather events. By transitioning to renewable energy, Europe reduces its dependence on fossil fuels and mitigates the effects of climate change. Renewable energy, coupled with energy storage systems, can enhance communities' resilience and help them withstand increasingly severe weather events. Renewable energy ensures a reliable electricity supply amid widespread damage from floods, provides backup power to fire stations during wildfires, and restores power to villages cut off during severe storms. As Europe navigates through new climate challenges, transitioning to clean energy becomes a vital tool to help us ensure a safer and more sustainable future in the face of these extreme weather events.

Want to know more about CBI’s work to achieve a carbon neutral economy in Europe? Subscribe to our newsletter here.

NEWS RELEASE - 17 November 2023

A new call for research proposals to support advanced lead battery innovation for energy storage systems (ESS) has been launched by the Consortium for Battery Innovation (CBI), the world’s only pre-competitive lead battery research consortium.

We are seeing an unprecedented effort to implement climate targets across the globe, led by the ambitious commitments by the European Union to become climate-neutral by 2050 and by the US to reduce emissions by 50% by 2030. According to Avicenne Energy (CBI’s Market Report 2023), the ESS market is forecasted to grow from 237 GWh in 2022 to 616 GWh in 2030. Batteries stand out as one of the big facilitators of this global shift to clean energy considering any scale of implementation, from industries to residences.

Recent analyses agree that a significant increase in battery demand will occur by 2030. Noteworthy examples are the forecast by the International Renewable Energy Agency (IRENA) that cumulative global renewable energy battery storage capacity will increase from 17 GW in 2020 to 359 GW in 2030 and estimates by the International Energy Agency (IEA) showing battery storage capacity for solar power integration only will increase at least five times by 2030. Demand will be so large it cannot be met by one battery technology alone. Such prognoses are a significant opportunity for growth of the lead battery market as a potential technology that can meet all the technical requirements on a mass market scale.

Building on the research priorities and research and innovation pathways defined on CBI’s Technical Roadmap, this call for proposals aims to stimulate projects further demonstrating improvements in lead battery performance for ESS applications. Dr Matthew Raiford, Senior Manager of CBI’s technical program, said: “The growth of the battery energy storage market is a great opportunity for advanced lead batteries, and the industry is committed to showing progress toward batteries that last longer and have higher energy density. CBI’s research program and this new request for proposals will directly contribute to that goal.”

CBI’s open call specifies two work proposal possibilities consisting of a) technoeconomic analyses of lead battery ESS or b) material science studies of failure of lead batteries in ESS. Submission of proposals is open until 22nd January 2024. More information on the desired work and guidelines for proposals is available here.

About the Consortium for Battery Innovation (CBI)

For more than 25 years, CBI has delivered cutting-edge research taking lead batteries to a new level for energy storage and automotive applications. With an expert panel made up of the world’s leading battery manufacturers and research specialists, CBI is setting the standard for advanced lead batteries and the next generation of energy storage. For more information, visit our website: http://www.batteryinnovation.org

Dr. Matthew Raiford is available for interview. For more information, please contact CBI’s media contact: Nicola Filizola, +32 489 17 76 60; nicola.filizola@batteryinnovation.org

Press release

Brussels, 9 November 2023

A system using advanced lead batteries to power a micro electric tractor tailored to the African market was selected as one of the finalists of the Milken-Motsepe Prize in Green Energy.

This innovative tractor design is being developed in Aftrak, a groundbreaking project funded by Innovate UK. The initiative brings together expertise from the Consortium for Battery Innovation (CBI), Loughborough University and UK- & Malawi-based charity Tiyeni, and the support of lead battery manufacturer VARTA.

Microgrid solutions for off-grid rural communities have high costs of implementation and maintenance that often cannot be covered by the communities, dissuading infrastructure investments. Aftrak is addressing this challenge by combining a solar energy microgrid with a micro electric tractor to mechanise land preparation. The tractor accelerates the implementation of Deep Bed Farming, an agricultural methodology developed by Tiyeni especially designed for Malawian soils. This system can provide a significant agricultural revenue boost to sustain microgrid-related costs and encourage further energy access investments.

Lead batteries inbuilt in the micro electric tractor play a central role in this green energy system, storing solar energy and providing it during land preparation activities. Dr Carl Telford, member of the Aftrak team and CBI Senior Research and Innovation Manager, said: “This is a very promising application of lead batteries that can bring real positive impact to rural communities. Having the recognition by the Milken Institute and the Motsepe Foundation is an important endorsement of the viability of lead batteries in green energy solutions.”

The Milken-Motsepe Prize in Green Energy is a global competition to reward innovators working to increase access to green, renewable energy in Africa. This year, over 160 teams from 36 countries presented their visionary ideas to the jury.

Selected as one of the five finalists, the Aftrak team will receive $70,000 in funding to further develop and test the system in a live field demonstration in South Africa in February 2024. Aftrak also remains in the competition for the final prize of $1 million, whose winner will be announced in May 2024.

About the Consortium for Battery Innovation (CBI)

For more than 25 years, CBI has delivered cutting-edge research taking lead batteries to a new level for energy storage and automotive applications. With an expert panel made up of the world’s leading battery manufacturers and research specialists, CBI is setting the standard for advanced lead batteries and the next generation of energy storage. For more information, visit our website: http://www.batteryinnovation.org

Dr Carl Telford is available for interview. For more information, please contact CBI’s media contact: Nicola Filizola, +32 489 17 76 60; nicola.filizola@batteryinnovation.org

Europe’s bold plan for clean air and economic growth

Climate change is unfolding right before our eyes. While discussions surrounding it have persisted for decades, the time for mere discourse has passed. This year, we saw Arctic sea ice hit record lows during winter, endangering polar wildlife and accelerating global warming. In contrast to the ice decline, Europe experienced devastating floods in many countries. Heavy rains and high river levels caused widespread flooding, affecting communities and infrastructure. These are not isolated incidents but signs that our planet is in distress. It is now crucial to translate words into action. That's precisely where the European Commission’s Fit for 55 package takes the stage. As a vital part of the EU's Green Deal, this visionary plan is strategically crafted to tackle the pressing challenges of climate change. Its main objective is to reduce greenhouse gas emissions in the European Union by at least 55% by 2030. As the world heats up and our environment gets sadly more unpredictable, Fit for 55 steers towards a greener, more sustainable future.

At the heart of this change is energy storage. In the context of the Fit for 55 package, there are several reasons highlighting its importance. Energy storage fuels the transition to environmentally friendly transportation and green mobility. This is possible through innovations like smart grids and battery systems powering electric buses in urban areas. Such integration of energy storage with public transportation not only reduces emissions but also makes green mobility accessible. Energy storage opens up job opportunities and boosts local communities. Furthermore, it is crucial in making energy more affordable, offering a safety net for those grappling with rising energy costs.

Driving the energy transition

As a result of the Fit for 55 initiative, energy storage operates on three essential fronts: improving air quality, generating job opportunities, and stabilising energy prices.

Air pollution is a serious problem affecting millions of people around the world. It can cause respiratory problems, heart disease, and cancer. Improving air quality is one of the key goals of the Fit for 55 package. It sets a bold target: zero emissions from new cars and vans by 2035. Energy storage is a vital driver in this journey to reduced air pollution and eco-friendly mobility.

Electric cars are the ambassadors of emission-free transport, and energy storage has the ability to power them. Energy storage also provides backup power for charging stations, ensuring that electric car owners can always find a place to recharge. Electric cars produce fewer emissions than traditional diesel-powered cars, and increasing their use helps to improve air quality. It is a stride towards a future defined by greener travel, with less smog and more fresh, clean air.

Cities and towns all over Europe are tapping into the potential of energy storage, harnessing electricity from renewable sources like the sun and wind. This stored energy fuels the urban transit networks, providing a lifeline to buses and trams. The result? A sharp decline in air pollution, quieter streets, and reduced reliance on fossil fuels. Energy storage acts as a safety net for electric buses and trains, improving the resilience and reliability of public transportation systems. In the event of a power outage, energy storage can provide backup power, ensuring that the city's transport continues to operate. Energy storage becomes an indispensable sidekick as the world shifts towards green transportation, creating a healthier environment.

Added to the industrial new development, there is another aspect of European’s stagnating and lasting issue: high employment rates. The job market is evolving unprecedentedly, leaving job seekers and employers grappling with new challenges and opportunities. As the global appetite for renewable energy grows, so does the demand for a diverse and skilled workforce. The Fit for 55 package aims to create more job opportunities within the clean energy sector. Energy storage, among other clean energy solutions, calls for an array of professionals, from engineers and technicians to electricians and software developers.

When an energy storage company establishes a new factory in a rural area, it does not only bring job opportunities to the community but also stimulates the local economy. The ripple effect is significant, as various services are required to support the factory. Construction workers, transportation services, and material suppliers all benefit from the newfound wave of activity. This synergy, driven in no small part by energy storage, highlights the potential of clean energy to power our homes, livelihoods, and economies.

Affordable energy is a pressing concern for communities and individuals globally. The COVID-19 pandemic and the war in Ukraine have aggravated the energy crisis, pushing energy prices to record highs. This is having a devastating impact on people and businesses, particularly those who are already struggling to make ends meet. The Fit for 55 package seeks to make energy more wallet-friendly for everyone, and energy storage is central to this vision.

Energy storage allows storing electricity during quiet hours when it's less expensive and tapping into these reserves when electricity prices skyrocket during peak demand. It's akin to purchasing energy at a discount rate and seeing savings grow.

Energy storage fosters self-reliance, particularly in regions prone to power hiccups or environmental concerns. Community solar initiatives, often supported by energy storage, are expanding access to solar energy, cutting the cords to the traditional power grid. This approach delivers a double victory, benefiting our finances and the planet's well-being.

Integrating an energy storage system for homeowners with solar panels complies with having a personal vault for energy. During the day, the excess energy is safely stored away. This energy is later used to lighten homes without sending electricity bills soaring. Energy storage systems are transforming the energy landscape, addressing the energy affordability crisis and making it more accessible for everyone.

Towards a greener future

While the Fit for 55 package may initially seem like a distant, abstract concept, its impact is already spreading through our daily lives. Together with energy storage, this visionary strategy has the potential to redefine our homes, our cities, and our communities. Energy storage fuels the shift to environmentally friendly transportation, cleansing the streets and reducing our dependence on fossil fuels. Energy storage solutions create job opportunities, uplift local communities, and place affordable energy within reach.

When the Fit for 55 package and energy storage team up, they have the potential to transform societies, reshape our relationship with the environment, and pave the way for a greener, more sustainable world.

Uncovering the key role of energy storage in Europe's green revolution

In the scorching summer of 2023, Europe was gripping an unprecedented heatwave. This extreme weather triggered a series of devastating events, including wildfires raging through Southern France and droughts that left the water reservoirs in Spain critically low. Such disasters were a stark reminder of the pressing need to address climate change head-on, an undeniable call to action.

In response, the European Commission and the cities across the continent have united, propelling Europe toward a more environmentally conscious future. At the core of this collective effort lies the Effort Sharing Regulation, which assigns emission reduction targets to each member state. With their sights firmly set on these targets and a dedicated commitment to combat emissions, European cities are charting a course towards sustainability, driven by innovation and a shared vision of a greener tomorrow.

This article explores three local initiatives - Copenhagen’s and Barcelona’s Climate plans and Tallinn as Europe’s Green Capital. Together, they exemplify how cities actively invest in renewable energy, advocate for sustainable transportation, and advance emission reduction. What unites these cities is their reliance on energy storage, with batteries emerging as integral components within these systems.

A green wave all over Europe

In the heart of Catalonia, Barcelona takes a bold stance in Europe’s ongoing battle against climate change. The city’s Climate plan sets a clear course towards reducing emissions and embracing renewable energy. At the forefront of this environmental mission are energy storage systems, with time-tested batteries powering businesses and homes across the city.

Barcelona’s first energy community epitomises this shift. Along the bustling Barcelona Port, solar panels soak in radiant Mediterranean sun. What sets this community apart is its ability to capture excess solar energy, preventing it from going to waste. Instead, it’s harnessed by energy storage systems. This stored energy becomes a precious resource, fueling essential port operations, from lighting to refrigeration. The Barcelona Port stands as an exemplary testament to the transformative potential of energy storage, pushing the city toward its climate goals one watt at a time.

Copenhagen has set an ambitious goal: to become the world’s first carbon-neutral capital by 2050, as outlined in its Climate plan. This visionary concept encompasses many initiatives, all connected by a central theme, energy storage.

A standout feature of the plan is Copenhagen’s extensive electric bus fleet, powered by battery energy storage systems. These systems store the energy that propels emission-free buses along the city’s bustling streets. In 2021, Copenhagen made waves by introducing 100 electric buses, to reduce annual greenhouse emissions by 5,000 tons. The city’s vision stretches even further, anticipating 50,000 electric vehicles on its roads by 2025, with advanced energy storage technologies seamlessly integrating modernity into urban life.

Copenhagen’s Climate plan encompasses initiatives ranging from retrofitting buildings with energy-efficient technologies to harnessing wind turbines and photovoltaic systems. In this vibrant metropolis, we witness the potential that arises from the marriage of renewable energy and energy storage solutions.

One of Europe's greenest cities is Tallinn. This progressive city with mediaeval charm was honoured with the European Green Capital 2023 title, recognising its ambitious sustainability plans. To achieve carbon neutrality, Tallinn is making substantial investments in renewable energy and energy-efficient initiatives. The city’s strategic approach to sustainability hinges on energy storage and the development of a smart grid, using digital technology to manage the flow of electricity.

A shining example of Tallinn’s commitment to energy storage is Ülemiste City Energy Storage Park. A robust energy storage system is nested within the park, ensuring no clean energy goes to waste. The park reduces the city's dependence on polluting fossil fuels and paves the way for increased local clean energy generation.

Tallinn’s mayor, Mihhail Kõlvart, firmly believes cities will be crucial in achieving European climate and sustainability targets. “European Green Capitals need to take leadership in creating sustainable, resilient and inclusive cities of the future to ensure a high-quality living environment,” stated Kõlvart, emphasising the value of collaboration among cities.

A sustainable energy storage transition

These local initiatives showcase the proactive spirit of European cities in the battle against climate change. In their stories, energy storage is a bridge connecting renewable energy to our daily lives. In Copenhagen, energy storage ensures swift and modern public transportation. In Tallinn, it fuels the city’s green revolution. In Barcelona, it keeps the bustling port community in motion.

With their progressive climate plans, these cities remind us of the importance of energy storage and its role in achieving the goals set by the Effort Sharing Regulation and the European Green Deal. By hopping on the energy storage bandwagon, cities across Europe are speeding toward a sustainable and low-carbon future.

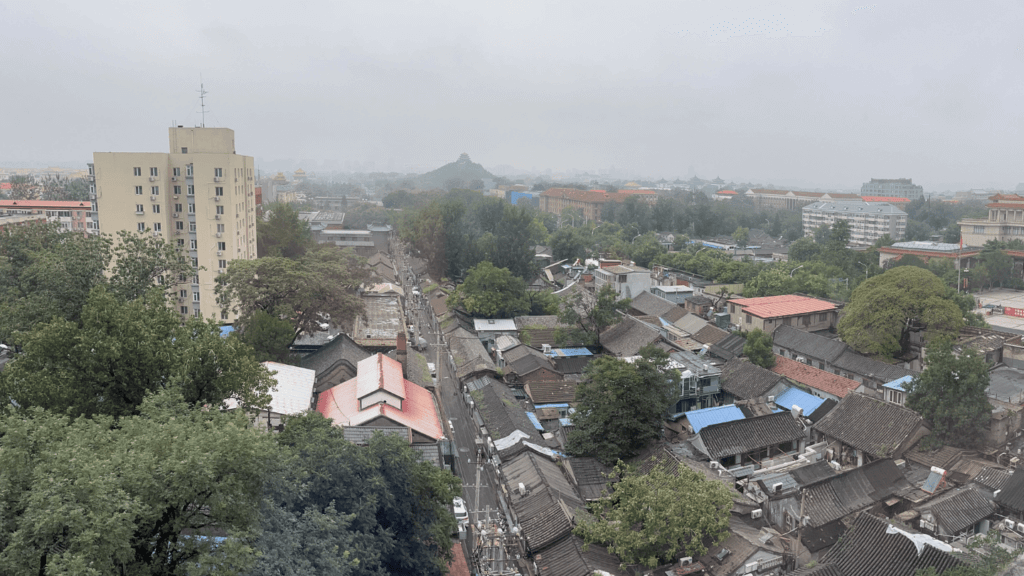

New Report Reveals How Lead Batteries are Featured in Chinese Energy Storage Systems

As the global power industry wrestles with the need to expand energy storage to accommodate renewable generation and meet soaring demand for electricity overall, a new CHR Metals Limited report states that countries like China are shifting some focus toward lead batteries over lithium for battery energy storage systems.

“The growth of lead battery energy storage systems in Asia, especially in China, is promising, driven by efforts to reduce fossil fuel use and achieve net-zero goals,” said Dr. Alistair Davidson, director of the Consortium for Battery Innovation. “With the energy storage market expected to exceed 400 GW by 2030, the CHR Metals analysis highlights significant opportunities for lead battery projects regionally and globally.”

Currently, only lithium-ion and lead batteries operate on a scale sufficient to meet demand, representing over 98 percent of the rechargeable battery market through 2030.

Lead batteries, known for their efficiency and reliability, continue to play a vital role in backup power for critical infrastructure, hybrid automotive, and motive power applications. Advanced lead batteries emerge as an ideal solution for energy storage, boasting superior performance, safety, and scalability to align with the U.S. and E.U.'s net-zero emission goals for 2050.

This week’s CHR Metals Limited Report also notes:

Contrary to misconceptions, lead batteries stand out as the most recycled and innovative products globally, minimizing the carbon footprint by utilizing recycled materials. Over 97 percent of lead batteries in North America and Europe are collected and recycled, with 85 percent of the recycled lead used in manufacturing new batteries—a testament to the circular economy in action. (Source: Association of Battery Recyclers)

Lead batteries can help deliver on climate-neutral pledges and provide energy resiliency in specific applications.

“Despite ongoing misconceptions, ongoing research and innovation have propelled advanced lead batteries to impressive strides in performance over the past decade,” added Davidson. “These advancements, including improved cycle life, lifetime, and overall energy efficiency, translate into substantial benefits in terms of total cost of ownership and reliability.”

While embracing an overall diversification of energy sources and plans to increase renewables, the versatility and proven performance of advanced lead batteries position them as a scalable and cost-effective solution to meet today's demands and future energy storage needs.

The lead battery industry could be in line for a $10 billion share of the burgeoning energy storage market within the next decade.

Research into upcoming projects and opportunities indicated that the ESS landscape is forecast to be 550GWh by 2030 with a value of $30-$50 billion for all battery technologies.

The lead battery industry has set its sights on securing 100GWh of that potentially lucrative ESS market.

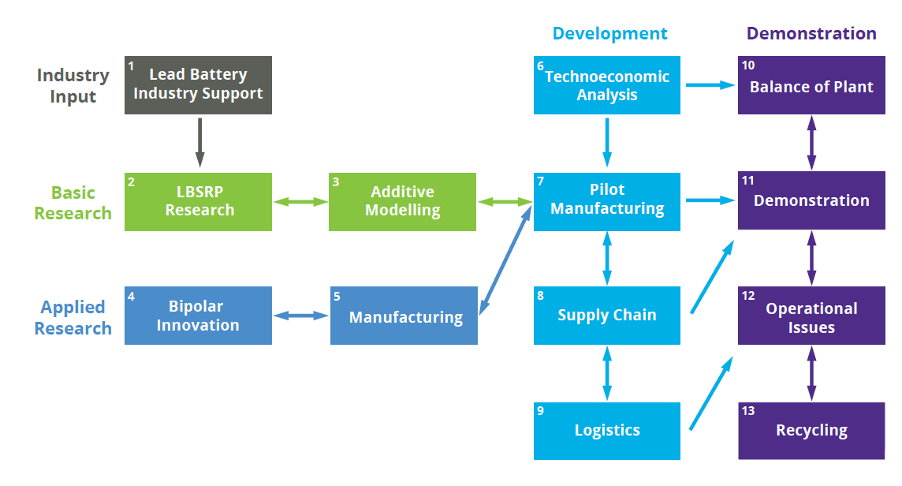

CBI launched its first technical roadmap in 2019 setting specific goals for the end of 2022.

“It was all really market-driven. We used those targets to select our program. And the result of the

projects that we funded have pretty much shown that we delivered on these goals that we set.”

There are now batteries on the market, primarily from our members in the US and Asia, that meet that criteria.

This means there are now have advanced lead batteries on the market-oriented toward ESS that have an impressive globalized cost of ownership for the system, says Raiford.

“The way we view it as battery scientists is cycle life — most key stakeholders look at it from total cost of ownership.

“So we see stationary batteries now that really perform along the lines of lithium.”

Read the full article from Batteries International

The Department of Energy (DOE) held its Energy Storage Grand Challenge Summit (ESGC) online and in Atlanta, GA on July 25-27, 2023.

Dr. Alyssa McQuilling, CBI’s U.S. Research and Innovation Manager, shared her thoughts and key takeaways from the event.

McQuilling noted that this is an unprecedented time for the development of energy storage with historic investments being made by the federal government to aid in commercialization.

As the DOE and other agencies are taking an “all of the above" approach to meeting the demands of a modern grid; there’s room for all the technologies to meet customers’ needs for a reliable grid (while also maintaining affordability).

At CBI, we encourage participation from all technologies to meet the growing global energy storage demand. CBI organized a response from the U.S. industry, and DOE ESGC efforts used the feedback from CBI members in a DOE Lead Battery Lift-off Report.

In this report, an in-depth analysis of lead battery innovation pathways was conducted, resulting in portfolios of lead battery improvements capable of helping the DOE reach the 0.05$/kWh/energy throughput goal outlined in the ESGC. These improvements include advanced manufacturing, improving cycle life, advanced control algorithms, standardization of devices and protocols, and demonstration projects to understand the impact of scaling on cost.

At the same time, we recognize how well-suited lead batteries are because they are a cost-effective, safe, and reliable solution. DOE recognizes lead batteries for this value as part of the energy storage solution as they currently represent much of the market.

Another takeaway is the ongoing emphasis on U.S. manufacturing, jobs, and ensuring that historically underserved communities also benefit through adopting energy storage technologies.

As a result, it will become increasingly important to make new connections that can accelerate growth in the industry because (again) the speed at which things are developing is unprecedented. These connections are critical and include collaboration and working across industries.

In the last session of the summit, the discussion focused on ROVI, or Rapid Operational Validation Initiative, (part of a collaborative effort from 6 national labs) to figure out how to model system performance/degradation/failure for different battery technologies by combining approximately one year of system data with machine learning/AI modeling approaches to figure out how the system will perform over a 15 to 20 year lifetime.

CBI is answering the many DOE opportunities by utilizing the breadth and expertise of our membership and bringing in key institutions and systems providers. These collaborative teams are poised to deliver a high-performing, sustainable, domestic solution to meet the many goals of the ESGC.

Below are two Energy Storage Innovation reports that were recently released:

A solar and lead battery-powered tractor, that is being developed as a farming solution for Africa, was named a semifinalist for the Milken–Motsepe Prize in Green Energy. The competition rewards projects who expand access to reliable, affordable, and sustainable electricity in Africa.

AfTrak or Africa Tractor, is a prototype program funded by Innovate UK as part of its Energy Catalyst Round 9. The program was one of 20 teams selected to advance to the Semifinalist Round for a competition by the Milken Institute and the Motsepe Foundation. Semifinalists receive $20,000 for the continued development and testing of their designs, as well as complimentary access to a Stanford Online course to help build their businesses.

AfTrak was selected from over 160 entrants around the world, in over 36 countries.

This potentially revolutionary tractor design, featuring lead batteries, is an African farming project created in collaboration between the Consortium for Battery Innovation (CBI), UK- & Malawi-based charity Tiyeni, and Loughborough University.

“We are delighted to be selected as a semifinalist in this prestigious competition—a reflection of the inspiration and technical capabilities of the Loughborough and Tiyeni teams. It’s also a great indicator of CBI’s ambitions.” said Carl Telford, Senior R&I Manager at CBI.

Across large areas of Malawi, under the few inches of topsoil, there is a heavily compacted layer of rock-hard earth through which plants cannot penetrate. Tiyeni has created an innovative agricultural method called Deep Bed Farming (DBF). The tractor, being developed at Loughborough University, will be a low-cost, hand-operated, solution for farming in the difficult soil.

The proposed AfTrak project is a micro electric tractor capable of mechanizing land preparation in line with Tiyeni’s Deep Bed Farming to prepare soil to a depth of 400mm.

For this program, AfTrak aims to provide an affordable green energy solution in sub-Saharan Africa, utilize a solar array and lead battery system to power micro electric tractors for Deep Bed Farming, and create a self-sustaining model for decentralized energy access.

An independent panel of expert judges determined the 20 teams receiving funding. Moving forward in the competition involves semifinalist teams demonstrating the effectiveness of their ideas in field tests.

They will be evaluated for their ability to:

After the Semifinalist Round, judges will select five finalist teams to conduct another round of field tests in Africa. Then in May 2024, the judges will award a $1 million Grand Prize. A Runner-Up Prize of $250,000 will also be awarded.

The Milken Institute is a nonprofit, nonpartisan think tank focused on accelerating measurable progress. They bring together the best ideas and innovative resourcing to develop blueprints for tackling critical global issues.

The Milken–Motsepe Innovation Prize program is a series of multiyear, multimillion-dollar innovation competitions for technological solutions that accelerate progress toward the UN Sustainable Development Goals (SDGs).

One of the two innovation competitions in the program, the Milken–Motsepe Prize in Green Energy, aims to expand access to reliable, affordable, and sustainable electricity in Africa as an essential factor in achieving long-term economic growth and shared prosperity. The competition advances progress toward SDG 7 (ensuring access to affordable, reliable, sustainable, and modern energy for all).

The semi-finalists were announced on June 6, 2023.

More information:

NOTE: AfTrak is the second bid application to be awarded to CBI in the past year after LoCEL-H2, a sustainable microgrid project using lead batteries and a novel, lead-battery-enabled funded by the European Commission under the Horizon Europe program.

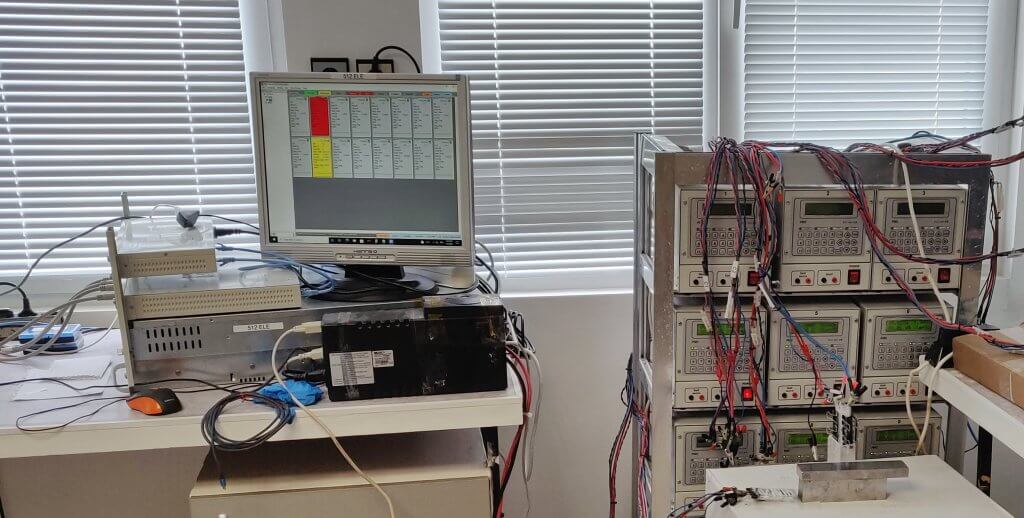

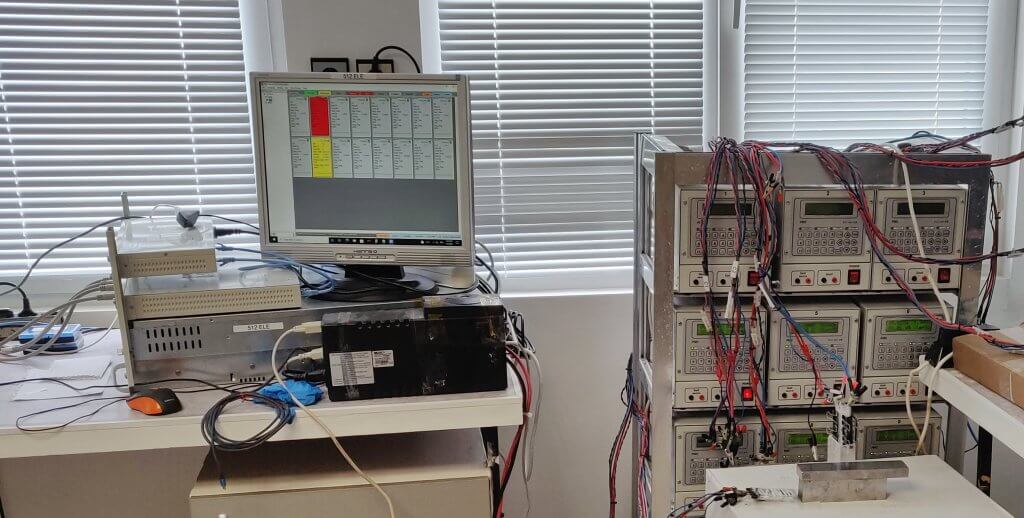

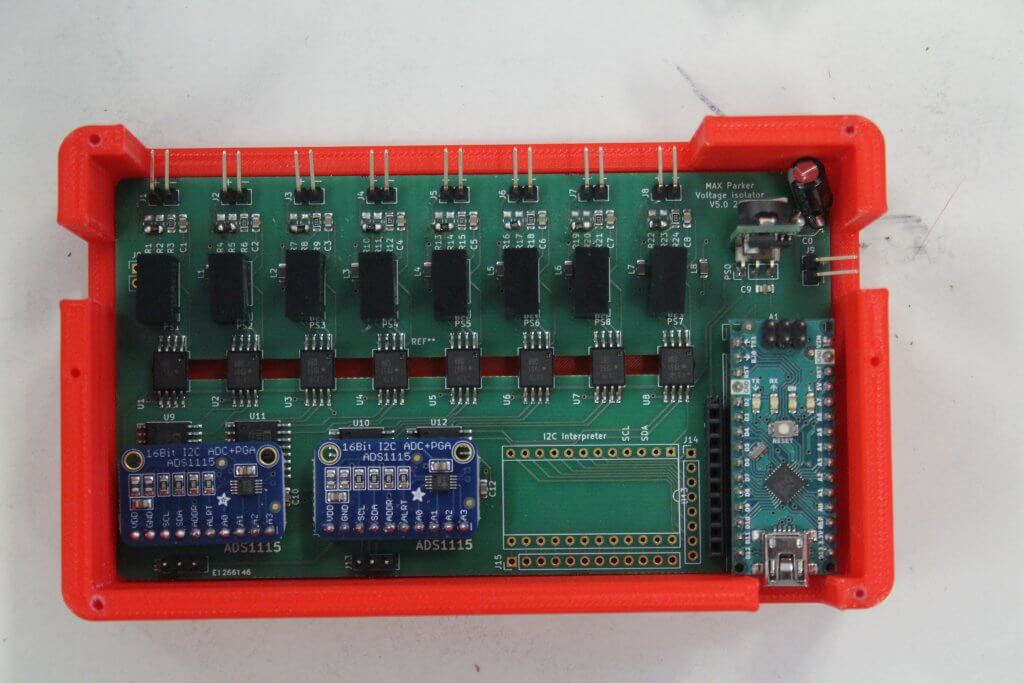

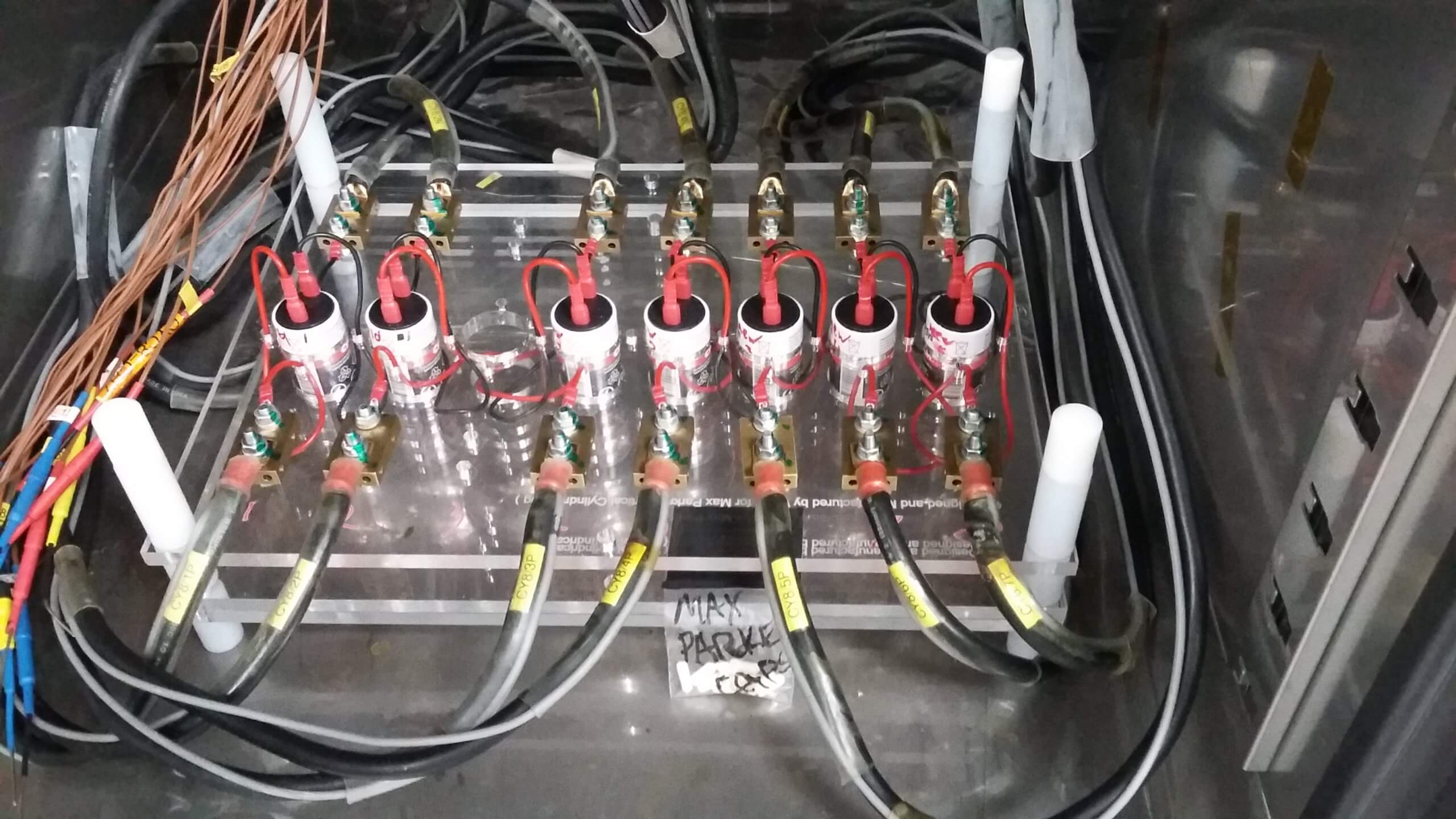

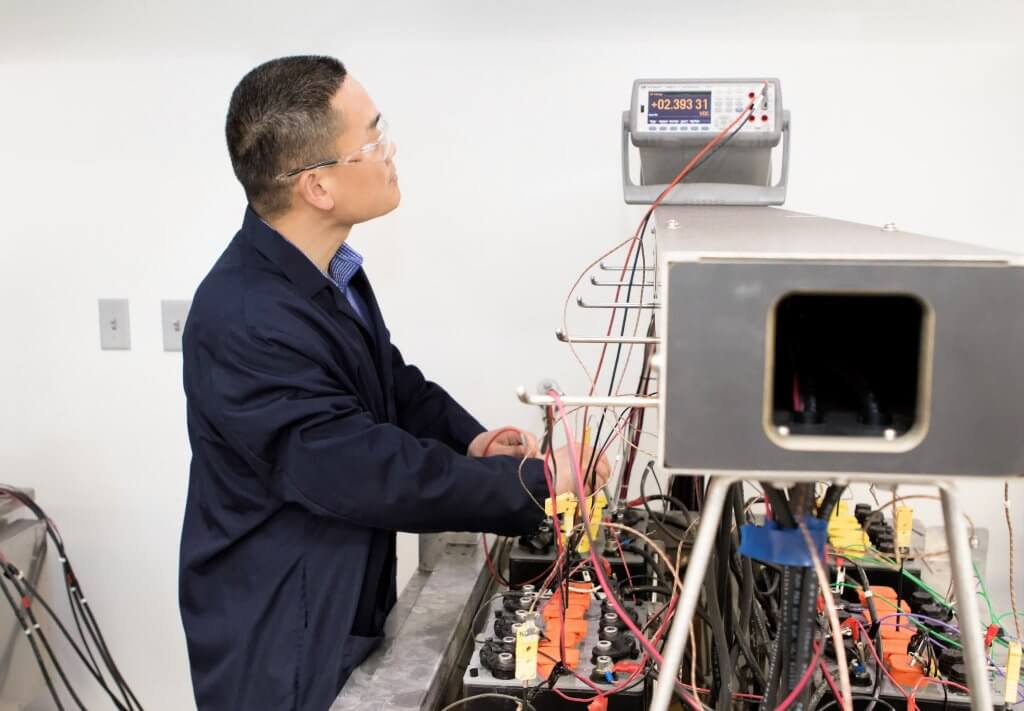

CBI is working jointly with Electric Applications Incorporated and C&D Technologies and Trojan Battery Company on a project to demonstrate the improved fast charging capability and increased total energy throughput of newly developed batteries.

“We’re looking to charge batteries faster for use in motive power applications and how it impacts AGM battery life,” said Shawn Peng, Senior Director of Energy Storage Research for C&D Technologies and Trojan Battery Company.

Peng explained that they are trying to determine the best approach and set of procedures for fast charge of a forklift – whether for a one-hour lunch break or overnight. This will help several companies more effectively utilize their motive and mobile fleets.

“We want to prove the best strategy for opportunity charging at 24/7 facilities, starting with a study on two different designs for a 2V battery to collect data and measure the KPIs.”

Specifically, the R&D department at C&D Technologies led by Peng, is initiating a 2V cell study to investigate and determine the proper charging current and voltage for a fast-charging protocol. The protocol will optimize the charging efficiency and reduce charging time through the life of batteries.

Then a third-party testing lab, Electric Applications Incorporated, will perform electrical testing of 8V batteries 48V packs using the optimized protocol. The 48V pack testing will be representative of what is used in motive power applications, like forklift traction batteries.

Peng added, “We want to see how far we can go with the technology to benefit the life and cost of lead acid batteries.”

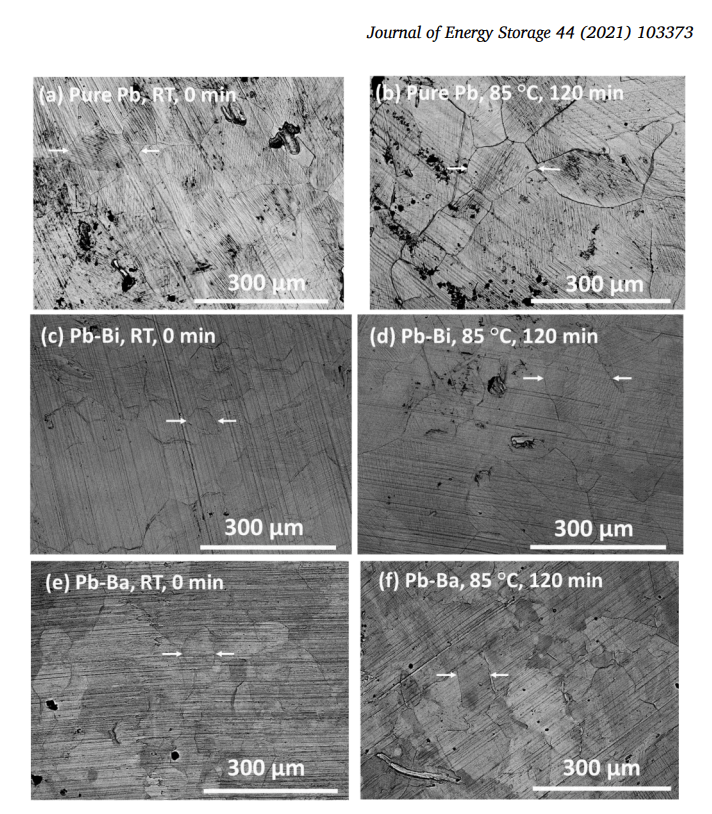

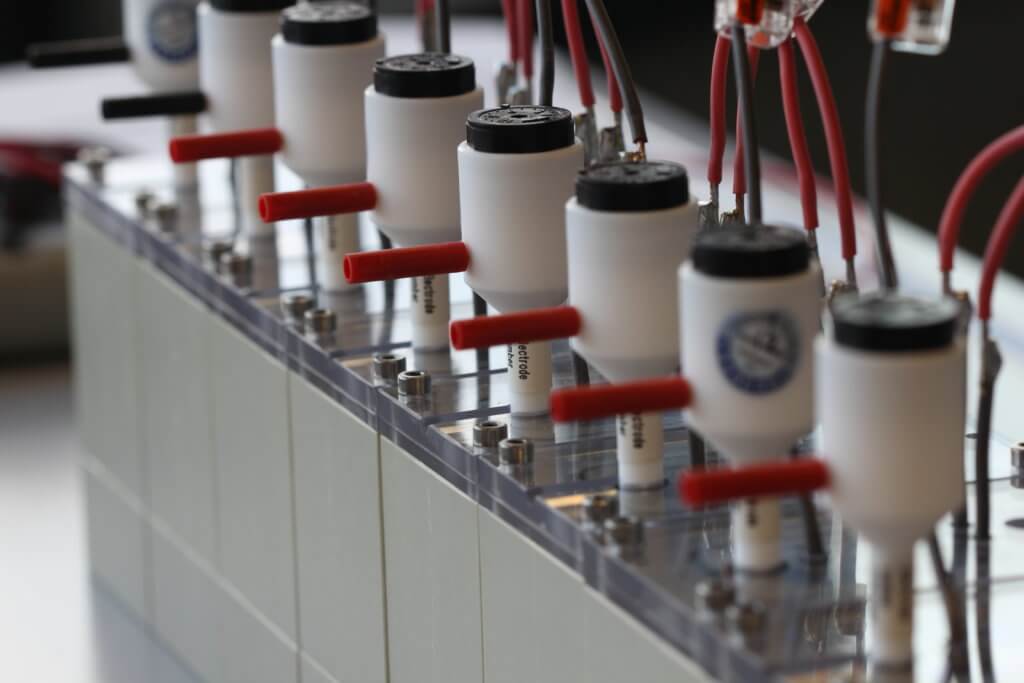

CBI spoke to Marcus Young, an Associate Professor and Associate Department Chair for the Undergraduate Program at the University of North Texas (UNT) about a two-year project that kicked off in February 2023 to look at materials in low voltage (12V) batteries for electric vehicles in an effort to further improve performance of lead batteries.

Lead batteries are still used in virtually every car on the road-from combustion engine vehicles through to Electric vehicles. Working alongside UNT, East Penn Manufacturing Company, and ECOBAT, CBI will further study the 12V battery electrochemical processes for materials and duty cycles common for lead batteries used in electric vehicles. By understanding more of how these batteries function in different charge conditions, temperature, and climate, we can determine what changes will attain a longer life span and better performance.

Electric vehicles rely on lead batteries to provide safety functionality in the case of failure of the main propulsion battery. This application is referred to as low voltage or auxiliary battery functionality. The lead batteries used in low-voltage EV applications use advanced alloys with different metallic additives to achieve current levels of performance. The study will focus on two specific additives, Ba (barium) and Bi (bismuth), and how their grain structure and influences on corrosion rates and crystallization would affect grid performance in the conditions found in EVs Previous research has shown that grids with Ba additives have reduced oxide formation, while Bi facilitates faster recrystallization.

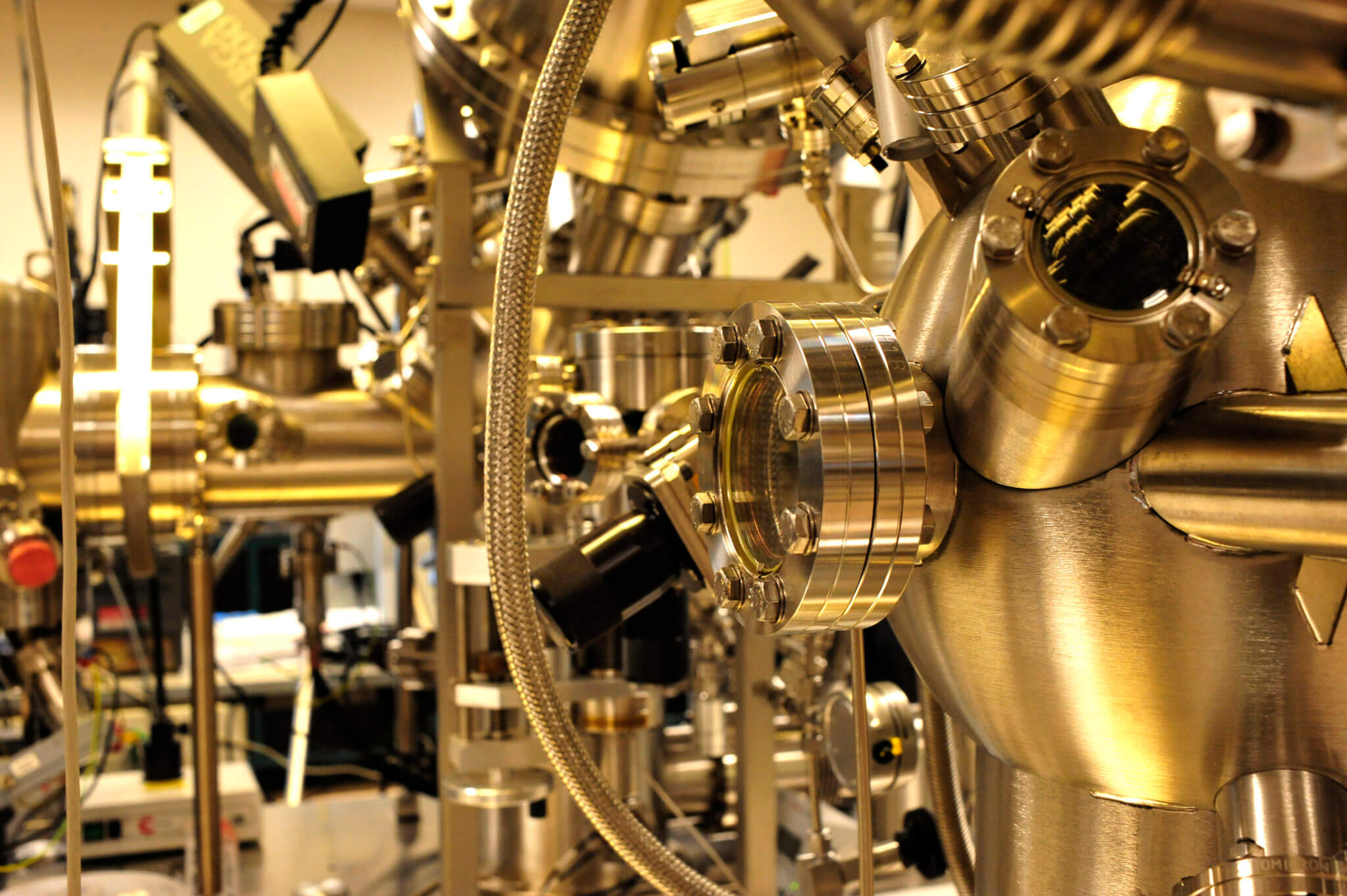

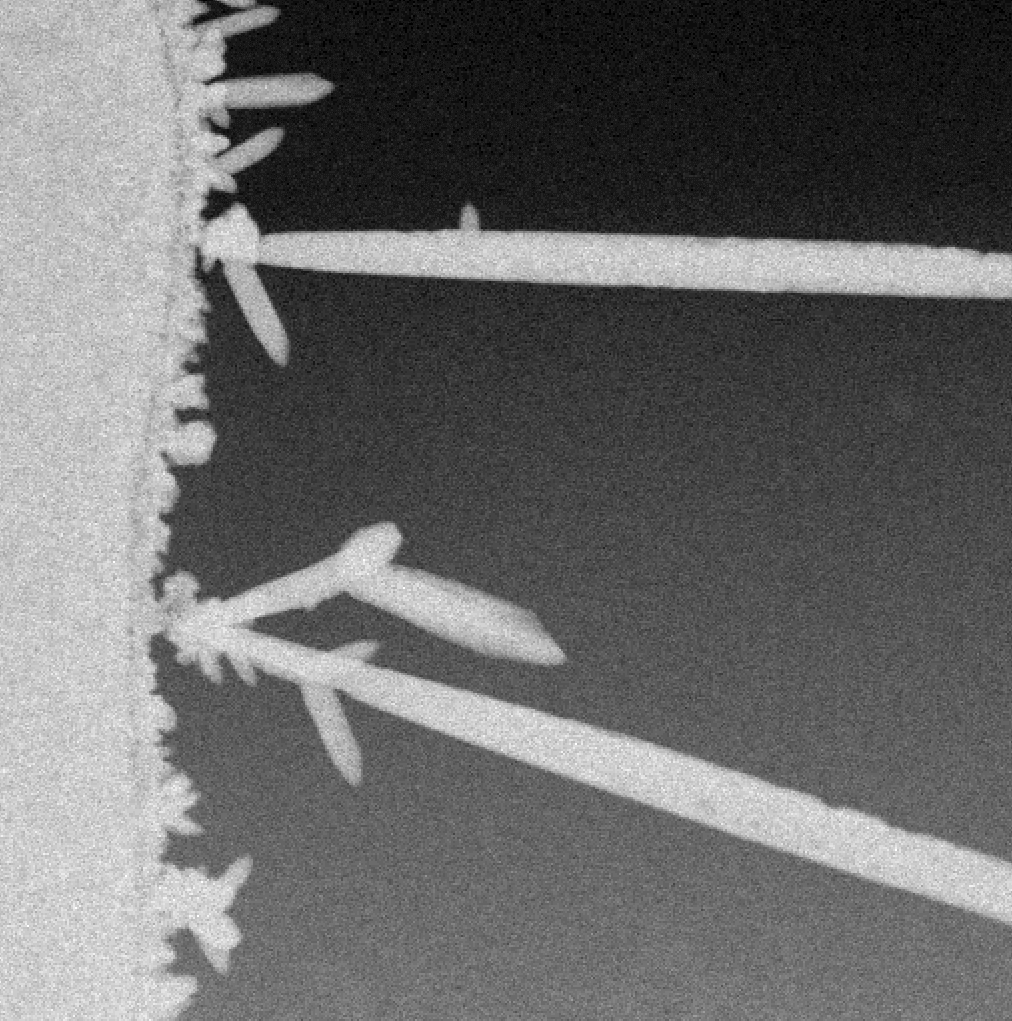

Using XRM – or X-ray microscopy, this project will investigate corrosion in batteries and look at the impact of Ba or Bi additives on battery life. The technique requires relatively thin samples to be used. Extremely thin pieces have been created and used on the nano scale, so that they can be x-rayed. As the x-ray penetrates through these panels, researchers will isolate areas of interest and study the impact of aging time to see a source(s) of potential problems.

Beyond lab-scale techniques, synchrotron experiments at the APS at Argonne National Laboratory will be used on large samples linking lab findings to real world lead battery products used in auxiliary applications.

“We’re making battery life better for everyone,” said Young. He explained that ultimately this research will impact daily users as the battery storage community creates faster, better, and more efficient sources.

Innovate UK Funding Malawi Trial of Low-Cost Tractor Featuring Lead Batteries and Solar Power for Deep Bed Farming

[LONDON, 20 April, 2023] AfTrak or Africa Tractor that will use solar and lead batteries, is both a prototype program and £270k project funded by Innovate UK as part of its Energy Catalyst Round 9 program, which officially kicked off in London today.

Innovate UK will fund a prototype and a sustainable business plan for a potentially revolutionary tractor design, featuring lead batteries. The UK program, which invests in innovative business ideas across all sectors, will support an African farming project created in collaboration between the Consortium for Battery Innovation (CBI), UK- & Malawi-based charity Tiyeni, and Loughborough University.

“The kick-off event exceeded expectations. We found it extremely valuable to network, not only with the Energy Catalyst team, but also with other innovators and stakeholders,” said AfTrak’s Project Manager, Dr. Carl Telford, a CBI’s senior research and innovation manager.

Across large areas of Malawi, under the few inches of topsoil, there is a heavily compacted layer of rock-hard earth through which plants cannot penetrate. Tiyeni has created an innovative agricultural method called Deep Bed Farming (DBF) through their extensive business experience and a network of agricultural advisers. The tractor, being developed at Loughborough University, will be a low-cost, hand-operated, solution for farming in this difficult soil.

Dr. Jonathan Wilson, a specialist in systems and mechanical engineering and leader of the Loughborough team notes, “We have a unique opportunity to take Tiyeni’s unique Deep Bed Farming technique and add Loughborough’s engineering & mechanization know-how to dramatically decrease upfront labor requirements.”

The proposed AfTrak system is a micro electric tractor capable of mechanizing land preparation in line with Tiyeni’s Deep Bed Farming to prepare the soil to a depth of 400mm.

Over 800 million people have no reliable access to electricity, primarily in sub-Saharan Africa, and rural regions of Asia. AfTrak also provides power for agricultural applications such as water irrigation and domestic applications such as phone charging, electric cooking, and lighting.

The AfTrak tractor will be trialed in Malawi by the Tiyeni team, with a focus on enabling an important agricultural technique, Deep Bed Farming.

Tiyeni’s Country Director, Isaac Chavula comments, “This is a breakthrough. Finally, I can see a solution through the AfTrak tractors to break the hardpan soil that has long challenged farmers. By adopting the Deep Bed Farming technique, farmers can now envision relief with the AfTrak tractors.”

In this initiative, AfTrak aims to:

Tiyeni Executive Director Alex Gerard added, “I am so excited that Innovate UK has funded our project to accelerate the end of food insecurity in Malawi. Combining our innovative Deep Bed Farming method with a sustainable solar tractor, we could speed up the support for millions of small-holder farmers.”

Telford added, “This is a perfect application and new opportunity area for utilizing lead batteries. Moreover, the anticipated outcomes are valuable. It’s an exciting time for renewable energy and lead battery storage, as this mechanization of the Deep Bed Farming technique could be a game changer.”

About Consortium for Battery Innovation

The Consortium for Battery Innovation (CBI) is the world’s only global pre-competitive research organization funding research into lead batteries for energy storage, motive, and automotive applications. For more than 25 years, with its global membership of battery manufacturers, industry suppliers, research institutes, and universities, CBI has delivered cutting-edge research pushing the boundaries of innovation in lead battery technology, setting the standard for advanced lead batteries and the next generation of energy storage. For more information, visit our website: batteryinnovation.org

AfTrak is the second bid application to be awarded to CBI in the past year after LoCEL-H2, a sustainable microgrid project using lead batteries and a novel, lead-battery-enabled funded by the European Commission under the Horizon Europe program.

About Loughborough University (LU)

The Wolfson School of Mechanical Electrical and Manufacturing Engineering is one of the biggest engineering schools of their kind in the UK with a research portfolio of around £52m. CREST (Centre for Renewable Energy Systems Technology) has a cohort of around 60 academics, researchers, and Ph.D. students and a good range of laboratory facilities for prototype manufacture and testing.

About Tiyeni UK (TU)

A UK based NGO who have funded the development of Deep Bed Farming (DBF) as a response to extreme food poverty within Malawi. The organization has grown year on year as support and demand for DBF has increased. Alex Gerard was appointed as a full-time Executive Director in 2021. Tiyeni’s board has extensive business experience and a network of agricultural advisers who have contributed to the development of DBF. Farmers adopting DBF can double their agricultural yields and all but eliminate requirements for expensive and environmentally damaging imported fertilizers.

Tiyeni Malawi (TM) is a Malawian company, funded by Tiyeni UK and operated at arm's length by a Malawian team, and led by an experienced Country Director, Isaac Monjo Chavula. Tiyeni continues to grow in size as DBF spreads across the country – especially since Malawi government approval. Historically the organization has focused on agriculture but is now diversifying into water management and carbon credits. Tiyeni is focused on ensuring all farmers in Malawi have access to training in DBF either through government extension workers, other NGOs, or through direct training for Tiyeni. The team is also developing the business model for smallholder deep bed farmers so they can leverage the other DBF benefits of carbon sequestration and water management.

The International Lead Association and Consortium for Battery Innovation have opened an office in Brussels to support the lead and lead battery value chains, and planned energy storage projects, as the EU strengthens its commitment to delivering net zero ambitions.

The decision to establish an EU base reinforces ILA’s long-term commitment to developing a sustainable lead value chain in Europe, as decision-makers focus on strengthening the EU’s strategic autonomy and embedding circular economy principles.