NEWS RELEASE

The new research – an EU collaboration managed by the Consortium for Battery Innovation – will focus on dynamic charge acceptance (DCA) and high-temperature durability in batteries used in the automotive sector. DCA is ability of a battery to capture instantaneous energy such as through regenerative braking.

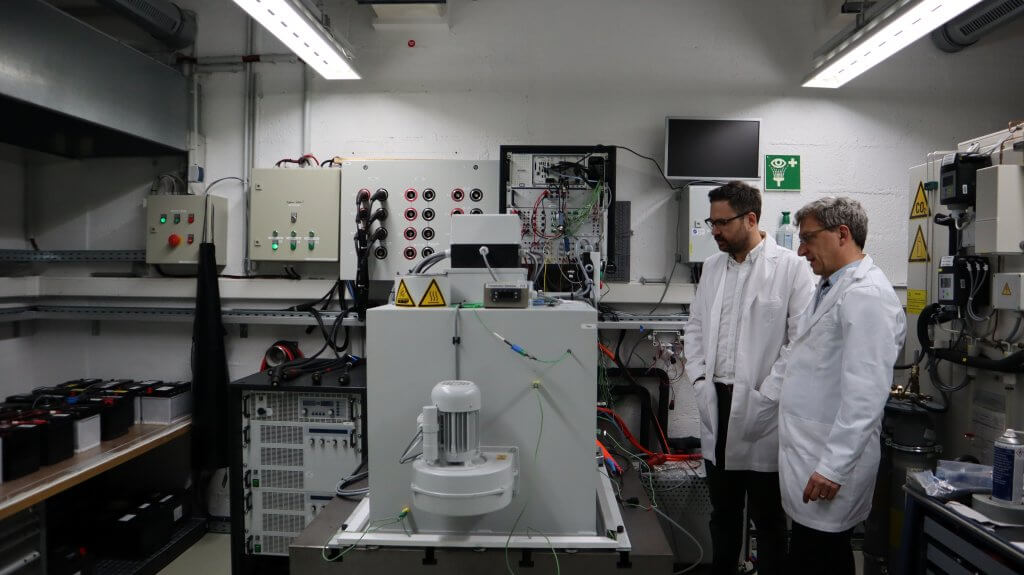

The European research partners include Ford Research and Innovation Center based in Aachen, Technische Universität Berlin (TU Berlin), MOLL Batterien and Fraunhofer Institute for Silicate Research ISC with its R&D Center Electromobility FZEB.

CBI’s global director Dr Alistair Davidson said: “The EU has a world-leading lead battery manufacturing capability and we have brokered this research collaboration with some of the most respected technical institutions in Europe to create advanced batteries that support a low carbon future. Regenerative braking using advanced lead batteries is key to achieving lower carbon emissions from cars and other vehicles. This project will help battery manufacturers improve the fuel economy and CO2emissions of hybrid vehicles.”

Ford’s Technical Specialist Dr Eckhard Karden said: “Car battery technology requires constant innovation and the work we’re doing at Ford will ensure that we use the most advanced lead batteries in our vehicles, ones that support the transition to a low carbon economy in hybrid vehicles.”

“In this project the Consortium for Battery Innovation and our European partners are helping to keep lead battery innovation at the forefront of technological improvements.”

The 18-month project will focus on performing a range of experiments on lead battery test cells, which are small laboratory versions of full-size batteries. The project will provide a thorough exploration of cell practices by exploring additive effects on DCA and high-temperature durability.

Taking the research a step further, the information gained from these screening studies will be essential for developing more accurate testing and methods to demonstrate enhancements in performance metrics such as DCA.

This information is essential for improving DCA of lead batteries for micro and mild-hybrid vehicles, a market expected to represent 80% of new vehicles in Europe, and over 60% globally by 2030. Lead batteries play a crucial role in this market by providing power for the essential functions on board such as starting, lighting, ignition (SLI), in addition to critical safety features such as driver assistance and autonomous driving functions. Advanced lead batteries in micro-hybrid vehicles are also able to store the energy generated during regenerative braking, delivering up to 10% in fuel savings and carbon emission reductions.

Over the last few years, CBI has been leading efforts to create a forum where the world’s leading lead battery manufacturers, car companies and researchers come together to discuss, explore and research the fundamental questions applicable to improving automotive lead batteries. The fusion takes place in DCA & Heat Workshops with the aim of optimizing high-temperature durability tests for advanced lead batteries. This work in crucial to determining pathways for improving DCA of lead batteries, and also developing tests demonstrating the strides in performance underway in the technology.

The Fraunhofer ISC, as experts in material development and electrochemical analysis, will investigate the effect of specially designed carbon additives on high-temperature durability. TU Berlin’s tasks will involve electrical tests on cell level as well as modelling, whilst MOLL, as a leading producer for enhanced flooded batteries (EFB), contributes with electrodes and knowledge regarding experimental test cells. Ford will provide the battery test data as well as vehicle integration background.

This latest research project between Ford, MOLL, Fraunhofer ISC and TU Berlin aligns well with efforts spearheaded by CBI to propel the next generation of advanced lead batteries for automotive applications. The knowledge generated from this research project will also feed into CBI’s growing research focus on lead batteries utilized in renewable energy storage applications as the batteries can have similar duty cycles to micro and mild-hybrid vehicles.

The project is part of the greater CBI technical program where the expansion of our research portfolio has involved adding projects applicable to energy storage systems for utility services. The renewable energy sector is a fast-growing area for lead batteries and an increasing number of installations are utilizing the technology for applications such as peak shaving, microgrids, frequency regulation and tariff management. CBI’s research program is focused on improving the cycle life of lead batteries for these applications which contributes to a lower TCO (total cost of ownership), a key requirement for batteries in ths application.

END

Notes to editors:

About CBI: