CBI is delighted that this year’s winner of the Battery Council International Innovation Award is ArcActive, a CBI member based in New Zealand. Their exciting new technology, AACarbon™, will play a significant role for the lead battery industry in reaching one of CBI’s highest priority targets set out in our technical roadmap.

Last year, CBI set a dynamic charge acceptance (DCA) target for automotive lead batteries of achieving 2A/Ah, which maximises the CO2 benefits of micro-and mild hybrid vehicles. As micro-hybrid vehicles are forecast to be the mass-market car for decades to come, the ability of AACarbon™ to improve lead battery DCA performance is ground-breaking.

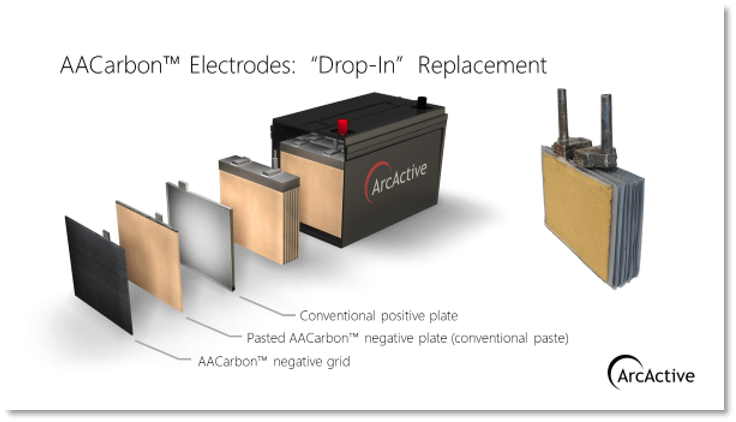

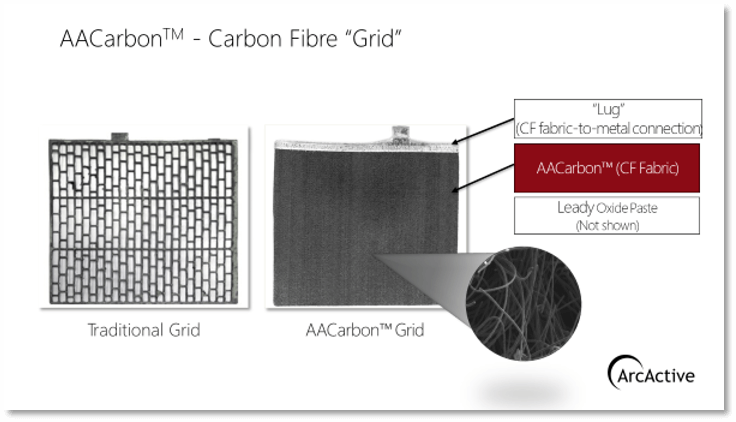

ArcActive have achieved this by re-engineering the negative electrode of the lead battery to remove the lead grid and replace it with a non-woven carbon fibre fabric into which the lead active material is inserted. The construction has shown to have excellent performance at partial state-of-charge (PSoC), a key technical requirement for both automotive and energy storage applications.

Not only does this technology have the ability to be manufactured at the speed and volume necessary for commercial viability, it also fits in gold standard of recycling rate that sets the lead battery apart from other chemistries.

We invited Stuart McKenzie, CEO of ArcActive, to share their innovation story with us.

+++

ArcActive was founded on a simple concept: to help make the decarbonisation of society affordable.

The business was founded in 2011 on Intellectual Property developed by Associate Professor John Abrahamson at the University of Canterbury. The IP relates to a novel carbon fibre material and early applications that were investigated included low energy light bulbs, ultracapacitors and solar cells before deciding on a novel, carbon fibre based negative electrode for the lead battery.

ArcActive has developed an innovative technology called AACarbon™ which has re-designed the negative electrode of the lead battery, replacing the lead grid with a non-woven carbon fibre fabric.

This innovative development provides a solution to a key technical challenge facing the automotive lead battery industry: achieving high and sustained DCA while having very low water consumption. The International Energy Agency has predicted that improvements in the efficiency of the non-electric car fleet will avoid the use of 9 million barrels of oil per day by 2040, and the use of lead batteries in virtually every vehicle on the road means this technology could significantly deliver on decarbonisation targets.

ArcActive batteries are unique in being able to achieve the very high DCA targets set by CBI of 2A/Ah. This maximises the CO2 benefits of micro-hybrid vehicles, while still achieving very low water consumption results of less than 3g/Ah.

Our batteries perform as well as normal enhanced flooded batteries (EFB) and absorptive glass mat (AGM) batteries on other automotive tests, demonstrating high performance when utilizing ArcActive’s technology. As with any new innovation, there is a modest on-cost in moving to this material, but there is a strong value proposition for car makers to adopt the material as a low-cost option for CO2 reduction.

Just as important as the performance levels of the innovation is the ability to manufacture the electrodes at speeds and volumes required to be commercially relevant in the lead battery industry. Developing the core processes has been a focus at ArcActive since its founding in 2011, and we are pleased to say that while work continues on this front, we have relevant, high volume throughput processes that enable the electrodes to be made at the very fine tolerances demanded by automotive applications.

This combination of superior technical performance and high-volume manufacturing processes has allowed ArcActive to secure partnerships with some of the leading battery companies in the lead battery industry, who are working towards taking this technology to market as we speak. Our technology is also fully compatible with the lead battery recycling process.

While ArcActive’s focus has been on achieving high DCA for micro-hybrid automotive batteries, we have also been investigating the possibility of this technology being used in other PSoC applications. We have early but promising results for use of the battery in PSoC applications to support renewable energy generation, demonstrating that ArcActive’s negative electrodes do not appear to degrade in PSoC use.

Innovation in lead batteries is vital due to evolving market requirements and the challenges faced by other battery chemistries. Higher performance in a range of applications at PSoC, such as automotive, battery energy storage and forklifts, is essential. ArcActive’s innovative technology is ideally suited to facilitate the continued opportunities for lead batteries in these diverse markets and helping to usher in greater levels of decarbonisation across the globe.