The LDES Consortium is a compelling initiative focused on advancing long-duration energy storage (LDES) technologies to enhance grid reliability and support the integration of renewable energy. In this interview, Dr. Alyssa McQuilling, CBI's Research & Innovation Manager, provides insights into the consortium's goals, the roles of its members, and the innovative solutions to push the boundaries of energy storage.

Can you give us a brief overview of the LDES Consortium and its primary goals?

Sure! The LDES Consortium is an exciting initiative that brings together diverse stakeholders to tackle the challenges of long-duration energy storage (LDES). The main aim is to overcome both technological and economic barriers to make LDES more viable and widespread.

What makes this consortium special is that it's 'technology agnostic ', meaning we're not biased towards any specific energy storage technology. We have experts from different energy storage technologies, such as chemical, mechanical, thermal, and all types of batteries, including lead and lithium. The idea is to address every aspect of the industry, from developing the workforce and managing the supply chain to creating policies and advancing technology, regardless of the specific technology used.

What roles do you and Dr. Matt Raiford, CBI's Technical Director, play within the LDES Consortium, and what are the 'tiger teams' you're involved with?

Matt and I are involved in several 'tiger teams' within the consortium. These teams are focused groups that tackle specific challenges related to long duration energy storage. Each team is dedicated to addressing a unique aspect of the LDES landscape.

Between the two of us, we're active in about eight tiger teams, where we attend meetings, provide feedback, and help refine the challenges and recommendations alongside other industry experts.

Uniting experts for energy innovation

How does LDES differ from other types of energy storage, and why is it important?

That's a great question. LDES stands out because it can store energy for more than ten hours, which is crucial for ensuring the grid's reliability. Some technologies are perfect for shorter durations, while others can handle much longer storage times, even up to seasonal storage.

This capability is especially important as we integrate more renewable energy, which can be unpredictable, into the grid. In simple terms, LDES helps balance supply and demand, ensuring enough energy is available when it's needed the most. This makes it a key player in creating a stable and sustainable energy system.

You're leading the Workforce Development team. What does that entail, and why is it crucial for the project?

I'm the industry advisor for the Workforce Development team, which is led by Hope Corsair at Oak Ridge National Lab. Our team's mission is to determine what skills and training are needed to build a strong workforce for the LDES industry. We've examined current workforce needs and are making recommendations to help scale the industry and prepare for future demands.

This builds on my previous work with the NAATBatt Education Subcommittee, where we focused on the educational needs of the battery industry. Ensuring we have a skilled workforce is essential for the success of LDES technologies.

What are some of the big challenges you face in making LDES more common, and how are you addressing them?

One of the biggest challenges we face is the cost. For instance, the current systems are primarily designed for shorter durations, making them less cost-effective for longer storage needs. Another challenge is scaling up the supply chain for these newer technologies, which haven't been widely deployed yet.

To address these, we're working on creating new market structures and incentives for long-duration energy storage. We're also confident that as the industry gains more experience, costs will come down, and these technologies will become more affordable.

Can you share a success story or milestone the LDES Consortium has achieved so far?

Absolutely! One of our early successes has been the release of initial recommendations from our tiger teams. These drafts are currently under review and will help guide the consortium's future activities.

We're also planning our first in-person consortium meeting in September in California, which is expected to bring together up to 300 attendees. It's a great opportunity to build momentum and collaboration.

Building a sustainable energy ecosystem

Sustainability and environmental impact are critical concerns. How do these advanced energy storage solutions help create a greener and more sustainable future?

LDES is crucial for maintaining grid reliability as we increase the use of renewable energy sources. By storing energy for longer periods, LDES helps balance the intermittency of resources like wind and solar. Technologies like lead batteries provide long duration storage and have established recycling processes, supporting a more sustainable energy ecosystem.

What potential do LDES technologies hold for transforming the energy landscape in developed and developing regions?

LDES has the potential to improve how we use renewable energy by making it more reliable and accessible. It can be integrated into large national grids as well as smaller microgrids, which are particularly beneficial in developing regions. This flexibility can support broader electrification and sustainable development goals globally.

Looking ahead, what impact do you think LDES will have on our everyday lives and the global energy landscape?

I believe that LDES will become a seamless part of our power grid, supporting decarbonization and electrification efforts. It will ensure we have reliable power whenever it's needed, helping to make our energy systems more resilient and sustainable.

It will be interesting to see the development of new technologies and the lessons we can learn from existing ones to ensure that the industry's growth is sustainable. This starts from the extraction of raw materials, through manufacturing and the lifetime of the systems, all the way to the end of life and recycling/materials recovery.

This hybrid energy storage (ESS) system made of advanced lead and lithium batteries is currently the largest of its kind in Poland.

Strategically situated to enhance the Bystra Wind Farm in Northern Poland, this facility maximizes renewable energy usage and stabilize local energy supplies.

Through efficient energy time-shifting, the system provides a reliable power source during peak demand periods, lowering energy costs for industries and residents. It focuses on low-carbon technologies and high recycling rates, setting a new standard for energy solutions in the region.

| Location | Gdańsk County, Pomeranian Voivodeship, Poland |

| Project launch | October 2019 |

| Construction time | 12 months |

| Size of the system | advanced lead batteries: 26.9 MWh energy; 5 MW power | lithium batteries: 0.47 MWh energy; 1 MW power; 4.5-hour system |

| Battery type | 2 V advanced lead-carbon AGM batteries** and lithium batteries |

| Battery provider | Showa Denko Materials |

View CBI's Interactive Map of energy storage case studies

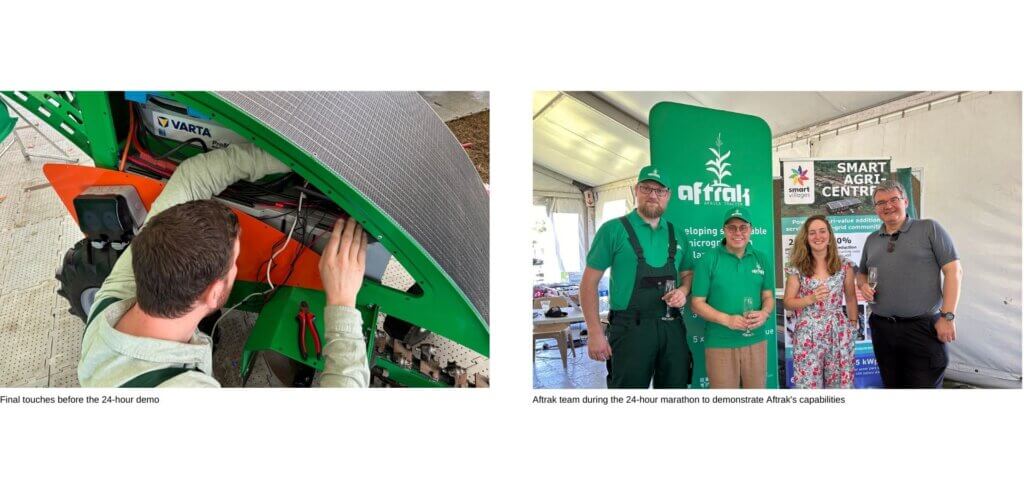

Aftrak is an innovative project combining solar microgrids and tailored tractors to empower smallholder farmers across Africa. In this interview, Dr. Carl Telford, CBI's Research & Innovation Director, talks about his trip to South Africa to demonstrate Aftrak's capabilities and their exciting journey as finalists for the Milken-Motsepe Prize in Green Energy.

Could you start by telling us a bit about Aftrak? What are you aiming to achieve with this initiative?

Aftrak is more than just a tractor. It's a complete ecosystem where agriculture boosts energy provision, and that energy revolutionises how we farm, leading to economic empowerment. It all started with Jonathan Wilson getting the idea for Aftrak in a hotel bar in Malawi during an Innovate UK field trip about 18 months ago.

Since then, we've secured over £300,000 in funding, designed and built two innovative tractors, and created a smart solar array to power them, all using green energy and recyclable materials. These tractors are easy to assemble and self-propelling, making them accessible to just about anyone. Plus, they use standard 12V truck batteries, so they can also power other essential devices like fridges and lights.

Aftrak made it as a finalist for the Milken-Motsepe Prize in Green Energy. How did you feel when you got the news? What could this mean for the project moving forward?

I was absolutely overjoyed but also a bit torn. On one hand, I couldn't believe we'd made it to the finals of such a prestigious competition. On the other hand, given all the innovation and hard work we've put in, I felt it was well-deserved. Being a finalist is a major achievement and opens up opportunities to expand and potentially create a whole new sector if we win!

24 hours of innovation

In February, you went to South Africa to demonstrate Aftrak's capabilities. Before heading to South Africa, what were you hoping to accomplish with the demo?

Our first goal was to have all the systems up and running smoothly. The team from Loughborough did an amazing job in this regard. Just getting the units shipped was hard enough in a short time. It was a real challenge, but seeing it all come together and work was just incredible.

How did people react to Aftrak, and what kind of feedback did you get right off the bat?

The response we received was overwhelmingly positive. People were impressed by our team's professionalism and how well everything was set up. They also seemed curious about the Aftrak unit itself, asking what it was, which led us to hold a few mini-training sessions. The Solar Array, in particular, got a lot of attention, with several attendees asking about purchasing it!

You and the team pulled off a 24-hour demo marathon. How did it go, and what were some standout moments?

The 24-hour demo was all about proving that our system could reliably generate 90kW/h of electricity. We exceeded those expectations, which was fantastic. We also wanted to prove the tractor worked. So we got it to dig in a sand pit and power a chest freezer and a tea urn. One funny moment was during the night when we could monitor energy usage and tell the exact time when the security team was making tea!

Redefining farming strategies

Deep bed farming is central to Aftrak's strategy. Can you tell us about this method and the difference it makes for the farmers and communities?

In some parts of Africa, a hard layer beneath the soil stops water and roots from penetrating, which is terrible for farming. Our partner Tiyeni developed Deep Bed Farming, which is a proven method that breaks up this layer, increasing crop yields, reducing flooding, and providing additional revenue for smallholder farmers. This technique, however, requires a lot of manual labour. Unless you use an Aftrak unit, which can do it for you.

Trips like these always have their surprises. What was something unexpected that happened during your time in South Africa?

One of the most unexpected things was a sudden power outage during our setup, which is a huge issue in South Africa. At one point, the entire demo tent went dark! However, we quickly hooked up our tractor to the power supply, lighting up the tent again and allowing everyone to continue their preparations.

With the announcement just around the corner, how do you feel about Aftrak's chances?

It may sound like a cliche, but making it to the final five is the real achievement. Just getting on the stage at the Milken conference is already a win for me. I believe we have a chance, but I don't have any additional expectations from this point on. I don't think we could have done any more in terms of preparation, and I have confidence in the team going forward, whether we win or not. That's all I have to say!

Aftrak's vision for the future

Looking down the road, what's the big dream for Aftrak? Where do you see it going, and what kind of impact do you hope it'll keep having?

It's very straightforward. We want to provide access to energy, double crop yield, reduce flooding, and enable economic and literal empowerment for millions of people in sub-Saharan Africa. However, to achieve this, we have a lot of work ahead of us.

We need to establish a company or, at least, find some way of building it on a large scale. Additionally, we must ensure the system is affordable for end-users. Despite these major challenges, we have made huge progress in the last 18 months, and I believe these are achievable.

Among all the milestones Aftrak has achieved so far, is there one that stands out as a 'wow' moment for you? What made it so memorable?

There are two. The first was when I saw the Aftrak unit in person at Loughborough University, all set to ship out to South Africa. It made all of it seem real. The second moment was when I arrived at the demo site in Stellenbosch. There, I saw all the equipment being set up, and I also met the team from Malawi for the first time in person.

At that point, I remembered Jonathan's initial idea that we had discussed in the hotel bar. A lead-battery tractor? At that time, I told him he was crazy. But the more we explored the idea, the more it made sense. In Stellenbosch, after seeing the people and the technology, my belief in what we were doing took off like a rocket.

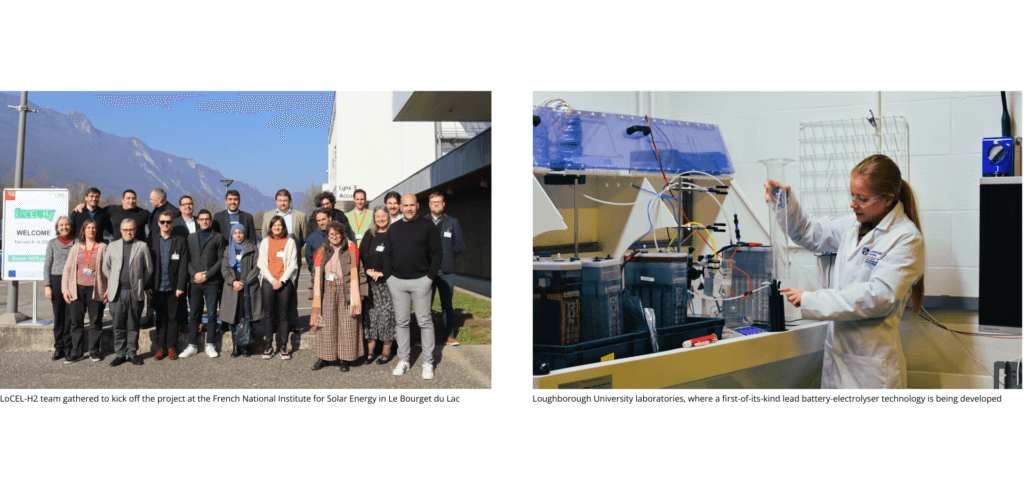

LoCEL-H2, a four-year initiative, is bringing innovative energy solutions to remote communities in Africa. In this interview, Dr. Athanasia-Maria Tompolidi, CBI's Research & Innovation Manager, discusses the project's goals, technological innovations, and commitment to community empowerment.

Let's start with the basics. Can you tell us what the LoCEL-H2 project is about and what it aims to achieve?

Of course. LoCEL-H2 is an innovative, four-year project under Horizon Europe that kicked-off in January 2023. It aims to bring scalable microgrid systems to isolated communities. These communities often lack steady access to energy like electricity and clean cooking facilities, which is taken for granted in the developed countries.

We combine solar power, advanced lead battery systems, and green hydrogen technology to offer sustainable and affordable energy solutions. And it is not just about technology. Empowering women in these communities is a big part of our project, especially in places like Zambia and Ivory Coast. We have an amazing team of partners from all over the globe, bringing diverse expertise to the table.

In a world teeming with green innovations and an urgent need for sustainable solutions, what sets LoCEL-H2 apart from the crowd, and why is it particularly crucial now?

LoCEL-H2 uniquely intertwines new technology with Social Sciences and Humanities (SSH) insights, hitting that crucial spot where technical solutions meet community needs head-on. We are in sync with the EU's hydrogen strategy and REPowerEU plan, introducing innovative ways for decarbonisation and independence from fossil fuels. By introducing green hydrogen solutions in developing countries, LoCEL-H2 contributes to global decarbonisation efforts and supports the European Green Deal's objectives.

Given the challenges posed by climate change, especially for vulnerable countries, projects like LoCEL-H2 provide essential tools for Climate Adaptation. It addresses critical issues such as food security, water supply, education, disasters risk reduction and public health.

From sunlight to energy storage

Innovation is key to the project. Could you explain how green hydrogen and advanced lead batteries work and why they're game-changers?

LoCEL-H2 stands on three innovation pillars. The first is a scalable, plug-and-play microgrid that uses solar energy to power communities. The second is a battery energy storage system tailored for households, small businesses, and community infrastructures to ensure a steady energy supply. The highlight is our community-shared battery-electrolyser, a novel system for energy storage and green hydrogen production.

Our vision with LoCEL-H2 is simple: we want to re-power the communities, quite literally. These smart innovations contribute to tackling energy poverty and provide sustainable solutions for those lacking access to reliable energy.

Could you give us an update on how the project is progressing and any significant milestones you've hit so far?

This past year has been remarkable. LoCEL-H2 has made significant progress thanks to our team's hard work and collaboration. We have mapped out stakeholder databases across continents. Our team has visited African and Pakistani villages to learn more about the communities and their energy needs. Key technical milestones of the project include the strategic design of our battery-electrolyser and advancements in energy storage solutions.

Our team has been meeting regularly, both online and in person, to ensure we stay on track. We had a face-to-face General Assembly in Naples in the autumn of 2023 and are looking forward to the upcoming one in Brilon, Germany, in the spring of 2024. It is very reviving to keep the in-person interaction.

Communities thriving on clean energy

Everyone's excited to see results. What are the short-term and long-term benefits LoCEL-H2 brings to the table?

LoCEL-H2 aims to change the way we access energy while promoting social and economic growth. Our focus is on innovative microgrid technology that combines battery-electrolyser and advanced lead battery energy storage to meet the unique needs of communities.

In short term, our goal is to empower communities by providing them with education and training on how to manage and benefit from these energy systems. We are working closely with people on site to ensure they are not just recipients but active players. This approach helps to create job opportunities and stimulate local economies.

In long term, we envision these efforts blossoming into sustainable, self-sufficient communities thriving on renewable energy. By introducing this technology, we're also helping to position the EU as a leader in clean energy innovation, supporting the green energy transition.

Beyond energy access, how does the project aim to influence societal change, for example?

At the heart of LoCEL-H2 is a deep commitment to societal change, particularly through empowering women in some of the world's most vulnerable areas.

We aim to see these women replacing old, smoky stoves with clean, green hydrogen, stepping into new roles, and changing the game in their communities. Our goal is to give them the time and resources they need to engage in social activities, achieve financial independence and be in charge of their own lives.

Moreover, with cleaner cooking, we are looking towards a greener future for them and the entire planet. It's a big vision, but with every step, we're closer to making it a reality.

Energy equity for sustainable future

Looking ahead, how do you plan to expand the reach of LoCEL-H2 to empower more communities worldwide?

Our aim for the future is to expand the impact of LoCEL-H2 beyond the current scope. We are working on integrating renewable energy into the very fabric of communities in need. This is particularly important when the world faces high energy demands and climate concerns, and sustainable solutions are needed more than ever.

Aligned with the EU's strategic priorities to mitigate climate change, LoCEL-H2 is committed to supporting the transition towards green energy across the globe, with a special focus on Africa, where the need is most acute. This can be achieved with collaborations with initiatives like Energising Africa and the Clean Cooking Manifesto. Increasing access to clean cooking is a topic that has been high on the global climate agenda, for example in the last United Nations Climate Change Conference COP28, and LoCEL-H2's technology is particularly well suited to be part of the solution.

Our approach is about connecting, sharing, and collective learning, which we believe to be some of the most valuable aspects of the project. We are sparking a movement through interactive webinars, training sessions, and collaboration with sister projects under Horizon Europe.

So, when discussing what's next for LoCEL-H2, it's all about showing that energy equity and a sustainable future are possible. LoCEL-H2 is dedicated to providing access to clean, green energy to communities worldwide. Its mission is to empower, inspire, and support the adoption of sustainable living practices worldwide.

Batteries are a fundamental driver of the green energy revolution. It is estimated that our society’s energy needs represent over 70% of all carbon emissions, with the largest shares coming from electricity and heat sources and transportation systems. The push to achieve net-zero is evident from numerous governmental initiatives such as the EU's commitment to cut carbon emissions by more than half by 2030, and global pacts such as the recent COP28 deliberations. To reach these goals means to effectively decarbonise the energy sector, and batteries will support the rollout of renewable energy infrastructure by providing energy storage capacity and reduce transport-related emissions by powering electric vehicles.

Batteries in energy markets are currently dominated by lithium-ion technology, but their employment in electric vehicles is given priority due to this technology’s unrivalled properties for this end use. This opens space for different technologies in other applications. Energy storage is a notable example, with battery energy storage capacity expected to grow twentyfold by 2030. All viable battery technologies will be needed to fulfil this soaring demand, and research & innovation to improve consolidated technologies is identified as an important way forward.

Lead batteries are currently the only other technology with well-established manufacturing and recycling infrastructure across the globe. But even if today's advanced lead batteries have come a long way from classic lead-acid car batteries in terms of overall performance, there are still various pathways for further improvements being discovered and explored.

The Consortium for Battery Innovation (CBI) is the only global lead battery pre-competitive research organisation. Our goals are to help deliver the advanced lead batteries needed for the energy transition and to demonstrate their power to bring real change. We do so by assessing market needs to define concrete research goals, by providing financial support to breakthrough projects through our Technical Program, and by establishing partnerships to develop pioneering advanced lead battery-based solutions.

In this overview, we discuss how some of our projects are paving the way to unlock the full potential of advanced lead batteries for the green energy transition.

The indispensable low-voltage ally

Electric vehicles are key for a decarbonised transport. As the nonstop evolution in automotive technology requires more and more from the main lithium-ion battery, smaller auxiliary batteries, also called low-voltage EV batteries, have been increasingly employed for safety back-up and supply power to specific electronic features. This means advanced lead batteries can work alongside lithium-ion batteries to ensure our future decarbonised road transport fleet is also safe.

CBI’s Technical Program has been supporting projects focused on automotive lead battery optimisation for start-stop, microhybrid and auxiliary use. Some encouraging results include improvements in the methodology of laboratory cell testing to investigate key parameters for automotive applications, and valuable insights on the role of additive formulations to enhance automotive battery performance. Ongoing studies, such as the investigation of microscopic changes in positive and negative electrodes during different charge conditions, along with future projects, will continue to provide guidance for better active material formulation and performance metrics.

Taking energy storage capability to the next level

The shift to renewable energy is just getting started, and more extensive rollout will be closely followed by a sharp increase in the need for energy storage systems to compensate for the intermittent nature of these energy sources. Global performance targets are aggressive and require different battery technologies with long lifetimes, high total energy throughput and low acquisition cost to meet technoeconomic needs. Our industry is focused on delivering longer lasting and more energy dense batteries to help meet the demand for utility, commercial, residential, and industrial energy storage applications.

Different projects supported by CBI’s Technical Program have been investigating advanced lead battery enhancements specifically for energy storage applications. Key findings so far include insights into barium sulphate additive configurations that can bring benefits to overall cycle life, and in-situ analyses during battery operation to understand charge and discharge processes and their products. More exciting results will come from projects and initiatives starting in 2024, including CBI’s involvement in the U.S. National Consortium for the Advancement of Long Duration Energy Storage Technologies. This will keep adding to our growing knowledge base and contributing to advanced lead battery performance improvement for energy storage.

Powering a just transition

The lack of access to both electricity and clean cooking, known as energy poverty, remains a pressing global issue. It is estimated that 775 million people lack access to electricity and 2.2 billion people lack access to clean cooking fuels, mostly in Sub-Saharan Africa and developing Asia. Providing universal clean energy access leaving no one behind is essential for a successful green energy transition. But the rollout of renewable energy in areas with no or incipient grid infrastructure is challenging, and lowering investment costs is a must. Through ongoing partnerships, we are demonstrating that the combination of microgrids and advanced lead battery storage is an excellent solution to provide clean and affordable energy for remote communities.

In an ongoing initiative funded by Horizon Europe, we are helping to develop a deployable clean energy solution with provision of electricity through prosumer-based solar microgrid coupled with an energy storage system made of advanced lead batteries. One core innovation in this battery energy storage system is the addition of an electrolyser to produce green hydrogen, which can be used as clean cooking fuel. By the end of the project in 2026, the team will deploy two full-scale pilots of this pioneering energy solution, one in Côte d'Ivoire and one in Zambia.

CBI is also contributing to another smart solution, this one already in testing phase: a solar energy microgrid with a combined micro electric tractor. Advanced lead batteries power both the microgrid energy storage system and the tractor. The project, funded by Innovate UK, aims to bring a 2-in-1 solution for rural communities by providing clean energy and optimising land preparation. Recent field demonstrations have shown the potential of the micro electric tractor to significantly increase crop yields, which will help to increase smallholder incomes. The solution has been selected as one of the finalists of a prestigious international green energy prize.

Novel solutions like these not only alleviate energy poverty issues but also provide a pathway toward citizen empowerment. They can substantially contribute to universal access to modern energy and to achieve other Sustainable Development Goals regarding poverty reduction, health and education.

This is why we believe the future is bright and green and we will continue to drive advanced lead battery innovation for sustainable development and a climate-resilient future.

Our colleagues Matt Raiford, CBI's Senior Technical Manager, and Alyssa McQuilling, CBI's Research and Innovation Manager, were featured in the latest Beyond Lithium podcast episode hosted by Nate Kirchhofer from BioZen Batteries. The discussion revolved around the work of CBI, research and innovations driving the industry, exciting new projects, unique features of advanced lead batteries and the future of energy storage.

CBI's projects and mission

Matt kicks off the conversation by outlining CBI's mission as a pre-competitive global research organisation with over 130 members worldwide. According to Matt, the priority of pre-competitive research lies in CBI's focus on applications and innovations benefiting the entire lead battery industry. "It's like taking a step back and looking at first principles," Nate summarises, as both guests noted.

The conversation reveals CBI's projects, showcasing an advanced lead battery technology for different applications. Matt and Alyssa shed light on CBI's involvement in global government funding opportunities, with recent projects spanning Europe and the UK. Alyssa introduces the current LoCEL-H2 project, featuring the unique battery-electrolyser. The technology stores energy to produce electricity on demand and utilises initially unwanted side reactions to produce hydrogen for cooking purposes. Another noteworthy project, Aftrak, showcases a solar advanced lead battery-powered tractor for deep-farming piloted in Africa. "These projects highlight something really important about batteries in general, that they can enable a whole new way of living," noted Matt.

A closer look at lead batteries

The podcast takes a turn as the team delves into the chemistry of lead batteries. "Lead batteries have been around for a hundred years, and they've been doing a lot of work," Nate acknowledges, addressing the never-ending question of getting people excited about lead. Dispelling misconceptions around lead batteries, Matt and Alyssa passionately discuss their unique benefits, including sustainability, an increasingly relevant factor in today's society. "Lead is the most recyclable product in the world," Matt emphasises, "This results in a recycling rate of over 99% in the US and Europe."

Energy storage takes centre stage in the conversation, as it has been emerging prominently in political dialogues worldwide. According to Matt, the performance rate of lead batteries is the main driver for energy storage. First invented in a French man's backyard, lead batteries evolved drastically into well-adapted products. As a scientist, Matt wondered how this technology didn't advance when he came across it years ago. The explanation is simple: there was no market driver. Nowadays, there is one. "That's what we're doing at the CBI. A lot of our research is inspired by the needs of the market," Matt explains.

The future of energy storage

"We need a lot of energy storage integrated into the grid as we decarbonise and electrify more," Alyssa states, touching on the need for diverse technologies to meet the escalating need for clean energy. This offers countless opportunities across sectors. The demand for energy storage and battery innovations go hand in hand. Improvements in cycle life and battery materials are a few examples of research in national labs, where new technologies and techniques are involved to better understand batteries at a fundamental level.

The podcast concludes with a forward-looking perspective on the future of energy storage. The energy storage sector's scale and pace of development promise a huge demand for batteries. "We see a steady growth for lead. For energy storage, the sky's a limit. We're talking about terawatt-hours batteries needed by 2030," Matt says, highlighting the increasing need for diverse technologies to coexist harmoniously. "We just have to create a cheap battery that lasts a long time," he concludes with a smile.

A special thanks to our colleagues, Matt Raiford and Alyssa McQuilling, for this insightful conversation, showcasing the work at CBI and providing valuable insights into the role of lead batteries in shaping a sustainable and energy-efficient future. Listen to the full podcast on the Beyond Lithium website.

NEWS RELEASE - 21 November 2023

The ELBC battery innovation conference has issued a call for papers ahead of the event which takes place in Milan, between September 16-19.

Jointly organised by the International Lead Association and Consortium for Battery Innovation, the event’s technical committee is seeking abstracts on all aspects of lead battery technology with a specific focus on:

Dr Alistair Davidson, Director of the Consortium for Battery Innovation, said: “This is always a much-anticipated event for the lead and lead battery industries and we’re looking for high quality submissions that showcase recent innovations and all the latest lead battery research.”

Abstracts can be submitted online by visiting www.elbcexpo.org

More than 1000 attendees are expected at the event in Milan which includes an expo with up to 140 exhibitors from across the lead battery value chain.

About the Consortium for Battery Innovation (CBI)

For more than 25 years, CBI has delivered cutting-edge research taking lead batteries to a new level for energy storage and automotive applications. With an expert panel made up of the world’s leading battery manufacturers and research specialists, CBI is setting the standard for advanced lead batteries and the next generation of energy storage.

Europe's commitment to renewable energy in the face of climate change

Climate change is happening right before our eyes and presenting new challenges for the world. European communities are grappling with increasingly frequent and intense extreme weather events that have profound impacts and demand our attention. The consequences are severe, from urban areas transformed into fiery landscapes during sweltering heat to towns inundated by floods.

The root cause of the climate crisis is our heavy reliance on fossil fuels. Burning these fuels releases greenhouse gases into the atmosphere, trapping heat and warming the planet. This disturbs the delicate balance of our climate system and intensifies the occurrence of extreme weather events. To face this crisis, we need to move towards a cleaner future with renewable energy sources such as solar and wind power. In addition to reducing our dependence on fossil fuels, renewable energy is essential for strengthening community resilience. This aligns with the European Union’s Green Deal, which outlines a comprehensive set of policies aimed to achieve a carbon-neutral economy by 2050.

European summer of extremes

This summer, Europe experienced a series of record heatwaves and devastating wildfires that have swept across the continent. The European Forest Fire Information System reports that up to 41% of the area burned in the EU is in Natura 2000 protected sites. In 2023 alone, wildfires have released more than 20 million tonnes of carbon dioxide into the atmosphere, exceeding the European average over the last two decades.

The Mediterranean region was hit hardest by this year's heat waves. The streets in Greece's ancient port town of Gytheio shimmered as temperatures climbed to an astonishing 46.4 degrees Celsius, setting a new record since record-keeping began in 2006. Life stood still in the sweltering heat, and the streets remained deserted. The heatwave also triggered a wave of wildfires that ravaged the countryside. Nearly 20,000 tourists abandoned Rhodes hotels due to the threat of wildfires, marking the largest evacuation of its kind in the country's history. The intensity of the heatwave caused widespread power outages and plunged towns into darkness. Hospitals struggled to maintain patient care, and businesses were forced to shut their doors.

In May 2023, Italy found itself in the grip of unforgiving weather. The tranquil rivers of Tuscany turned into raging torrents that surged through towns and villages, leaving destruction in their wake. Homes vanished beneath the rising waters, and critical infrastructure crumbled under the weight of the deluge. The downpours lasted 80 hours of relentless rainfall over six days, causing flooding and infrastructure collapse, leaving the affected areas in darkness. Over 20,000 citizens were forced to evacuate and seek refuge in temporary shelters such as schools, sports halls, and gyms.

Not only floods but also severe storms with strong winds are becoming a pressing concern in Europe. This year, Norway faced several relentless storms marked by a historic amount of rainfall. The Norwegian meteorological institute reported extremely heavy rainfall in parts of Norway, marking the strongest in the last 25 years. As winds and heavy rain swept across the region, trees were uprooted, flights faced delays, ferries stopped running, and power lines scummed to disruption. In cities like Oslo, people were urged to work from home. Meanwhile, in the small village of Bagn, nested in the heart of a valley surrounded by forests, landslides wreaked havoc, severing its residents from the outside world.

Researchers at Newcastle University predict extreme weather events will become more frequent due to the climate crisis. "Alongside drastically cutting emissions, countries must build more resilient infrastructure," the researchers said.

Renewable energy and climate resilience

In the face of a changing climate, Europe is at a crossroads. Floods, wildfires, and storms dominate the headlines. As extreme weather events become more frequent, the transition to renewable energy is necessary. The European Union recognises this need and has adopted bold initiatives such as the European Green Deal, a comprehensive roadmap to reach climate neutrality by 2050. Central to this strategy is the Fit for 55 initiative, which aims to reduce greenhouse gas emissions by at least 55% by 2030. Additionally, the RePower EU plan aims to decrease the dependency of the European Union on Russian fossil fuels and promote green energy.

These initiatives address the challenges highlighted by the extreme weather events. By transitioning to renewable energy, Europe reduces its dependence on fossil fuels and mitigates the effects of climate change. Renewable energy, coupled with energy storage systems, can enhance communities' resilience and help them withstand increasingly severe weather events. Renewable energy ensures a reliable electricity supply amid widespread damage from floods, provides backup power to fire stations during wildfires, and restores power to villages cut off during severe storms. As Europe navigates through new climate challenges, transitioning to clean energy becomes a vital tool to help us ensure a safer and more sustainable future in the face of these extreme weather events.

Want to know more about CBI’s work to achieve a carbon neutral economy in Europe? Subscribe to our newsletter here.

Funding: U.S. Department of Defense

Duration: January 2021 - May 2023

Project partners: Consortium for Battery Innovation, Paragon Solutions, Inc.

Objective: Develop transportable and robust lead battery energy storage systems that can be integrated into tactical microgrids

Funding: Innovate UK and Milken-Motsepe Prize in Green Energy

Duration: April 2023 – April 2024

Project partners: Consortium for Battery Innovation, Loughborough University, Tiyeni

Objective: Aftrak developed a green electricity solution for rural communities combining a solar energy microgrid with a micro electric tractor to mechanise land preparation.

Low-cost, Circular, plug & play, Off-grid Energy for remote Locations including Hydrogen

Funding: Horizon Europe

Duration: 1 January 2023 – 31 December 2026

Project partners: Consortium for Battery Innovation, Commissariat a l'Energie Atomique et aux Energies Alternatives, Hollingsworth & Vose, HOPPECKE Batteries, Lahore University of Management Sciences, Loughborough University, RHYDE, Sunkofa Energy, Università degli Studi di Napoli Federico II, University of Gabes

LoCEL-H2 (Low-cost, Circular, plug & play, Off-grid Energy for remote Locations including Hydrogen) is developing a new solution to bring renewable electricity and clean cooking fuel for off-grid communities.

The solution comprises three core technical innovations:

LoCEL-H2 will conduct two pilot programs, one located in Zambia and the other in Côte d’Ivoire, assessing each community’s energy needs and tailoring the solution in order to provide renewable energy and cooking fuel for approximately 30 households and businesses in each pilot.

For more information visit project's website: https://locelh2.org/

Europe’s bold plan for clean air and economic growth

Climate change is unfolding right before our eyes. While discussions surrounding it have persisted for decades, the time for mere discourse has passed. This year, we saw Arctic sea ice hit record lows during winter, endangering polar wildlife and accelerating global warming. In contrast to the ice decline, Europe experienced devastating floods in many countries. Heavy rains and high river levels caused widespread flooding, affecting communities and infrastructure. These are not isolated incidents but signs that our planet is in distress. It is now crucial to translate words into action. That's precisely where the European Commission’s Fit for 55 package takes the stage. As a vital part of the EU's Green Deal, this visionary plan is strategically crafted to tackle the pressing challenges of climate change. Its main objective is to reduce greenhouse gas emissions in the European Union by at least 55% by 2030. As the world heats up and our environment gets sadly more unpredictable, Fit for 55 steers towards a greener, more sustainable future.

At the heart of this change is energy storage. In the context of the Fit for 55 package, there are several reasons highlighting its importance. Energy storage fuels the transition to environmentally friendly transportation and green mobility. This is possible through innovations like smart grids and battery systems powering electric buses in urban areas. Such integration of energy storage with public transportation not only reduces emissions but also makes green mobility accessible. Energy storage opens up job opportunities and boosts local communities. Furthermore, it is crucial in making energy more affordable, offering a safety net for those grappling with rising energy costs.

Driving the energy transition

As a result of the Fit for 55 initiative, energy storage operates on three essential fronts: improving air quality, generating job opportunities, and stabilising energy prices.

Air pollution is a serious problem affecting millions of people around the world. It can cause respiratory problems, heart disease, and cancer. Improving air quality is one of the key goals of the Fit for 55 package. It sets a bold target: zero emissions from new cars and vans by 2035. Energy storage is a vital driver in this journey to reduced air pollution and eco-friendly mobility.

Electric cars are the ambassadors of emission-free transport, and energy storage has the ability to power them. Energy storage also provides backup power for charging stations, ensuring that electric car owners can always find a place to recharge. Electric cars produce fewer emissions than traditional diesel-powered cars, and increasing their use helps to improve air quality. It is a stride towards a future defined by greener travel, with less smog and more fresh, clean air.

Cities and towns all over Europe are tapping into the potential of energy storage, harnessing electricity from renewable sources like the sun and wind. This stored energy fuels the urban transit networks, providing a lifeline to buses and trams. The result? A sharp decline in air pollution, quieter streets, and reduced reliance on fossil fuels. Energy storage acts as a safety net for electric buses and trains, improving the resilience and reliability of public transportation systems. In the event of a power outage, energy storage can provide backup power, ensuring that the city's transport continues to operate. Energy storage becomes an indispensable sidekick as the world shifts towards green transportation, creating a healthier environment.

Added to the industrial new development, there is another aspect of European’s stagnating and lasting issue: high employment rates. The job market is evolving unprecedentedly, leaving job seekers and employers grappling with new challenges and opportunities. As the global appetite for renewable energy grows, so does the demand for a diverse and skilled workforce. The Fit for 55 package aims to create more job opportunities within the clean energy sector. Energy storage, among other clean energy solutions, calls for an array of professionals, from engineers and technicians to electricians and software developers.

When an energy storage company establishes a new factory in a rural area, it does not only bring job opportunities to the community but also stimulates the local economy. The ripple effect is significant, as various services are required to support the factory. Construction workers, transportation services, and material suppliers all benefit from the newfound wave of activity. This synergy, driven in no small part by energy storage, highlights the potential of clean energy to power our homes, livelihoods, and economies.

Affordable energy is a pressing concern for communities and individuals globally. The COVID-19 pandemic and the war in Ukraine have aggravated the energy crisis, pushing energy prices to record highs. This is having a devastating impact on people and businesses, particularly those who are already struggling to make ends meet. The Fit for 55 package seeks to make energy more wallet-friendly for everyone, and energy storage is central to this vision.

Energy storage allows storing electricity during quiet hours when it's less expensive and tapping into these reserves when electricity prices skyrocket during peak demand. It's akin to purchasing energy at a discount rate and seeing savings grow.

Energy storage fosters self-reliance, particularly in regions prone to power hiccups or environmental concerns. Community solar initiatives, often supported by energy storage, are expanding access to solar energy, cutting the cords to the traditional power grid. This approach delivers a double victory, benefiting our finances and the planet's well-being.

Integrating an energy storage system for homeowners with solar panels complies with having a personal vault for energy. During the day, the excess energy is safely stored away. This energy is later used to lighten homes without sending electricity bills soaring. Energy storage systems are transforming the energy landscape, addressing the energy affordability crisis and making it more accessible for everyone.

Towards a greener future

While the Fit for 55 package may initially seem like a distant, abstract concept, its impact is already spreading through our daily lives. Together with energy storage, this visionary strategy has the potential to redefine our homes, our cities, and our communities. Energy storage fuels the shift to environmentally friendly transportation, cleansing the streets and reducing our dependence on fossil fuels. Energy storage solutions create job opportunities, uplift local communities, and place affordable energy within reach.

When the Fit for 55 package and energy storage team up, they have the potential to transform societies, reshape our relationship with the environment, and pave the way for a greener, more sustainable world.

Uncovering the key role of energy storage in Europe's green revolution

In the scorching summer of 2023, Europe was gripping an unprecedented heatwave. This extreme weather triggered a series of devastating events, including wildfires raging through Southern France and droughts that left the water reservoirs in Spain critically low. Such disasters were a stark reminder of the pressing need to address climate change head-on, an undeniable call to action.

In response, the European Commission and the cities across the continent have united, propelling Europe toward a more environmentally conscious future. At the core of this collective effort lies the Effort Sharing Regulation, which assigns emission reduction targets to each member state. With their sights firmly set on these targets and a dedicated commitment to combat emissions, European cities are charting a course towards sustainability, driven by innovation and a shared vision of a greener tomorrow.

This article explores three local initiatives - Copenhagen’s and Barcelona’s Climate plans and Tallinn as Europe’s Green Capital. Together, they exemplify how cities actively invest in renewable energy, advocate for sustainable transportation, and advance emission reduction. What unites these cities is their reliance on energy storage, with batteries emerging as integral components within these systems.

A green wave all over Europe

In the heart of Catalonia, Barcelona takes a bold stance in Europe’s ongoing battle against climate change. The city’s Climate plan sets a clear course towards reducing emissions and embracing renewable energy. At the forefront of this environmental mission are energy storage systems, with time-tested batteries powering businesses and homes across the city.

Barcelona’s first energy community epitomises this shift. Along the bustling Barcelona Port, solar panels soak in radiant Mediterranean sun. What sets this community apart is its ability to capture excess solar energy, preventing it from going to waste. Instead, it’s harnessed by energy storage systems. This stored energy becomes a precious resource, fueling essential port operations, from lighting to refrigeration. The Barcelona Port stands as an exemplary testament to the transformative potential of energy storage, pushing the city toward its climate goals one watt at a time.

Copenhagen has set an ambitious goal: to become the world’s first carbon-neutral capital by 2050, as outlined in its Climate plan. This visionary concept encompasses many initiatives, all connected by a central theme, energy storage.

A standout feature of the plan is Copenhagen’s extensive electric bus fleet, powered by battery energy storage systems. These systems store the energy that propels emission-free buses along the city’s bustling streets. In 2021, Copenhagen made waves by introducing 100 electric buses, to reduce annual greenhouse emissions by 5,000 tons. The city’s vision stretches even further, anticipating 50,000 electric vehicles on its roads by 2025, with advanced energy storage technologies seamlessly integrating modernity into urban life.

Copenhagen’s Climate plan encompasses initiatives ranging from retrofitting buildings with energy-efficient technologies to harnessing wind turbines and photovoltaic systems. In this vibrant metropolis, we witness the potential that arises from the marriage of renewable energy and energy storage solutions.

One of Europe's greenest cities is Tallinn. This progressive city with mediaeval charm was honoured with the European Green Capital 2023 title, recognising its ambitious sustainability plans. To achieve carbon neutrality, Tallinn is making substantial investments in renewable energy and energy-efficient initiatives. The city’s strategic approach to sustainability hinges on energy storage and the development of a smart grid, using digital technology to manage the flow of electricity.

A shining example of Tallinn’s commitment to energy storage is Ülemiste City Energy Storage Park. A robust energy storage system is nested within the park, ensuring no clean energy goes to waste. The park reduces the city's dependence on polluting fossil fuels and paves the way for increased local clean energy generation.

Tallinn’s mayor, Mihhail Kõlvart, firmly believes cities will be crucial in achieving European climate and sustainability targets. “European Green Capitals need to take leadership in creating sustainable, resilient and inclusive cities of the future to ensure a high-quality living environment,” stated Kõlvart, emphasising the value of collaboration among cities.

A sustainable energy storage transition

These local initiatives showcase the proactive spirit of European cities in the battle against climate change. In their stories, energy storage is a bridge connecting renewable energy to our daily lives. In Copenhagen, energy storage ensures swift and modern public transportation. In Tallinn, it fuels the city’s green revolution. In Barcelona, it keeps the bustling port community in motion.

With their progressive climate plans, these cities remind us of the importance of energy storage and its role in achieving the goals set by the Effort Sharing Regulation and the European Green Deal. By hopping on the energy storage bandwagon, cities across Europe are speeding toward a sustainable and low-carbon future.

The European Energy Transition

By Nicola Filizola

As the world copes with the urgent need to address climate change and reduce greenhouse gas emissions, Europe has been leading the charge in transitioning to a cleaner and more sustainable energy future. The European energy transition is a comprehensive shift from traditional fossil fuels to renewable energy sources, such as wind, solar, hydro, and geothermal power. Among the critical components enabling this transformation, lead batteries have emerged as a key technology that plays a pivotal role in the transition's success. In this article, we will explore the energy transition in Europe and delve into the essential role that batteries are playing in shaping the continent's greener and brighter future.

The Growth of Renewable Energy in Europe

The European Union (EU) has been at the forefront of advocating for clean energy and sustainability. Through initiatives like the European Green Deal and the Paris Agreement, EU member states are committed to reducing their carbon emissions, fostering innovation in clean technologies, and achieving climate neutrality by 2050.

One of the main challenges of integrating renewable energy sources into the existing energy infrastructure is their intermittency. Solar and wind power, for instance, depend on weather conditions and daylight availability. To ensure a stable and reliable energy supply, an efficient energy storage system is essential, and that's where batteries come into the picture.

The Challenge of Intermittency

Unlike conventional power plants that can provide a consistent energy output, solar and wind power are dependent on weather conditions and natural variations. Cloudy days and calm winds can lead to a drop in power generation, causing fluctuations in the grid. This intermittency poses challenges to grid stability, and the power supply must be balanced in real-time to meet demand. If renewable energy sources are to dominate the energy mix, an effective and efficient energy storage solution is imperative to address this variability.

Batteries: The Key to Storing Renewable Energy

Batteries are essential components of the energy transition as they serve as a bridge between renewable energy generation and consumption. These energy storage systems can store surplus electricity when generation exceeds demand and release it when demand surpasses generation. In essence, batteries help to smooth out the intermittent nature of renewables and provide a stable supply of electricity to the grid.

Batteries act as buffers, absorbing excess energy during periods of high generation and releasing it when generation dips. By doing so, they stabilize the grid and ensure a steady supply of electricity, reducing the risk of blackouts and power disturbances. Moreover, batteries can respond rapidly to fluctuations in demand, providing grid operators with a valuable tool to manage the grid effectively.

The energy transition in Europe is also characterized by a shift towards decentralization, with an increasing number of small-scale renewable energy installations, such as rooftop solar panels and community wind farms. Batteries play a vital role in this decentralized energy landscape by enabling consumers to store and manage their locally generated energy. This promotes energy autonomy, reducing the reliance on centralized power plants and enhancing energy security.

Batteries make it possible to integrate a higher share of renewables into the grid. By storing excess energy during periods of high generation, batteries ensure that the energy is not wasted and can be used during times of low generation. This feature is particularly crucial during seasonal variations when renewable output may vary significantly.

Batteries also play a significant role in electrifying transportation, another essential aspect of the energy transition. The growth of electric vehicles (EVs) is dependent on advanced battery technology, allowing for longer driving ranges and faster charging times. Widespread EV adoption not only reduces greenhouse gas emissions from the transportation sector but also opens up the possibility of using EV batteries for grid storage through vehicle-to-grid (V2G) technology.

In conclusion

The energy transition in Europe represents a monumental effort to combat climate change and create a sustainable energy future. The integration of renewable energy sources is a crucial step in this journey, but their intermittent nature presents challenges that must be addressed. Lead batteries, together with other technologies, emerge as the silent protagonists, providing a robust and reliable energy storage solution. From enhancing grid stability and enabling renewable integration to empowering decentralized energy systems and fostering electric vehicle adoption, lead batteries will play a multifaceted role in reshaping Europe's energy landscape. As technology advances and costs continue to decline, the potential of batteries will only grow, propelling Europe towards a cleaner, greener, and more resilient energy future.

The lead battery industry could be in line for a $10 billion share of the burgeoning energy storage market within the next decade.

Research into upcoming projects and opportunities indicated that the ESS landscape is forecast to be 550GWh by 2030 with a value of $30-$50 billion for all battery technologies.

The lead battery industry has set its sights on securing 100GWh of that potentially lucrative ESS market.

CBI launched its first technical roadmap in 2019 setting specific goals for the end of 2022.

“It was all really market-driven. We used those targets to select our program. And the result of the

projects that we funded have pretty much shown that we delivered on these goals that we set.”

There are now batteries on the market, primarily from our members in the US and Asia, that meet that criteria.

This means there are now have advanced lead batteries on the market-oriented toward ESS that have an impressive globalized cost of ownership for the system, says Raiford.

“The way we view it as battery scientists is cycle life — most key stakeholders look at it from total cost of ownership.

“So we see stationary batteries now that really perform along the lines of lithium.”

Read the full article from Batteries International

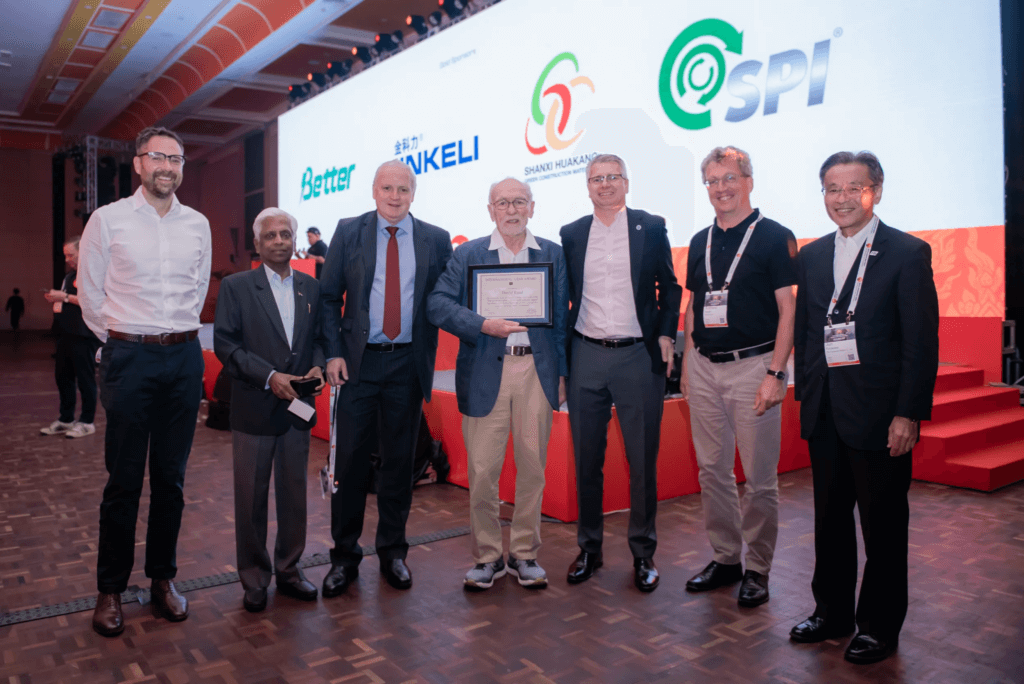

The Consortium for Battery Innovation connected with over 730 attendees from 42 different countries representing 319 different organizations in Siem Reap, Cambodia for the 20th Asian Battery Conference (20ABC) and the Recycle 100 International Secondary Lead Conference and Exhibition that featured global discussions on the world of lead, recycling, lead-acid batteries and energy storage.

CBI Senior Technical Manager, Dr. Matt Raiford said that lead batteries are made and produced in over 100 countries, and the Asian Battery Conference was a great venue to see how Asia, Africa, and other areas of the world are innovating and improving lead battery technology. For instance, CBI member companies, Hammond and Borregard, demonstrated deeper understandings of additive chemistry as a low threshold method to improve lead batteries for many different applications.

CBI participated in the line-up of over 45+ conference speakers during 20ABC to share our technical battery knowledge and insights with attendees with presentations that included:

The 20th Asian Battery Conference provided a chance to join several technical sessions providing valuable insights from industry leaders, market analysts and technical experts about the lead battery industry. Several speakers including CBI member companies presented innovations and advancements, such as new active material formulations and improvements in the manufacturing process, for several applications of lead batteries.

Dr. Begüm Bozkaya, CBI’s Technical Manager, shared that there are definitely future opportunities for lead battery technology in Asia and other continents of the world via the implementation of new developments to deliver cost-efficient, safe, and sustainable battery solutions.

8th International Secondary Lead & Battery Recycling Conference covered several aspects of lead recycling industry in Asia and Africa. Bozkaya shared that many of the speakers addressed the current issues related to environmental challenges, financial, and social risks in the secondary lead industry. It was beneficial for attendees as some of the ILA & CBI members also illustrated their new techniques and developments in recycling of lead batteries.

Recycle 100 illustrated the ins and outs of running battery recycling centers - the heart of lead battery sustainability. Raiford was intrigued by ongoing improvements at Asian recycling operations, especially in increasing recycling efficiency - and how these improvements were presented to representatives from dozens of countries.

The city of Siem Reap, Cambodia was an amazing host and we enjoyed seeing all the beautiful areas in that region. The 20ABC was a successful event from all angles – including the achievement from the event’s charity initiative. The "ONE Minute Giveback", exceeded organizer’s and sponsor Sorfin Yoshimura’s expectations, by raising over $22,000.00 USD to help fund a bed in the Oncology Department of Angkor Hospital for Children.

We look forward to next year’s events and continuing the technical conversations around lead batteries.

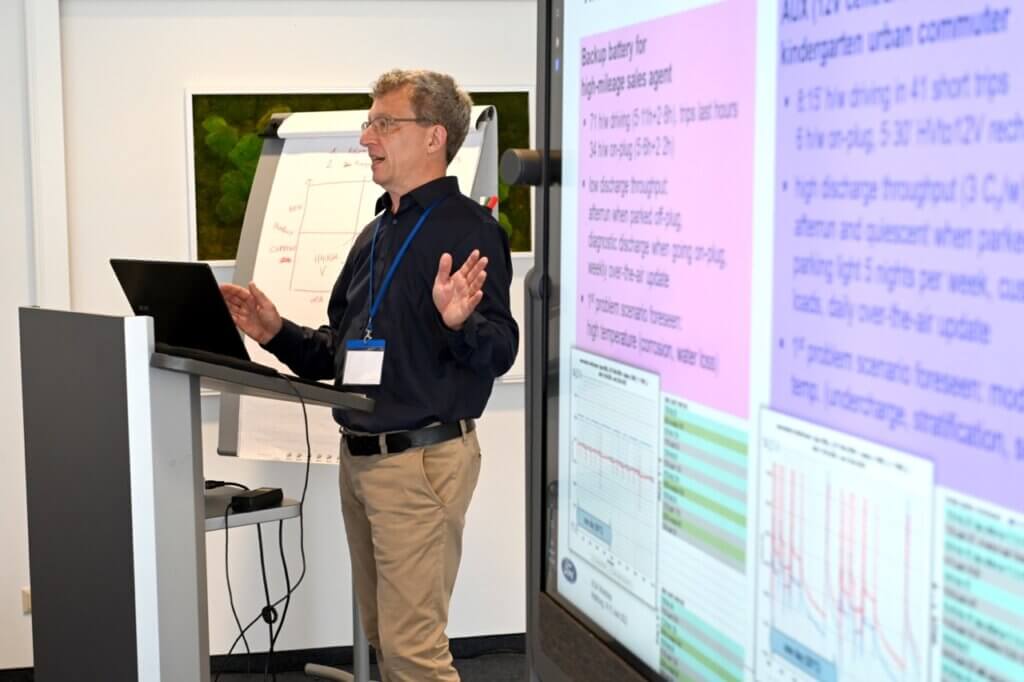

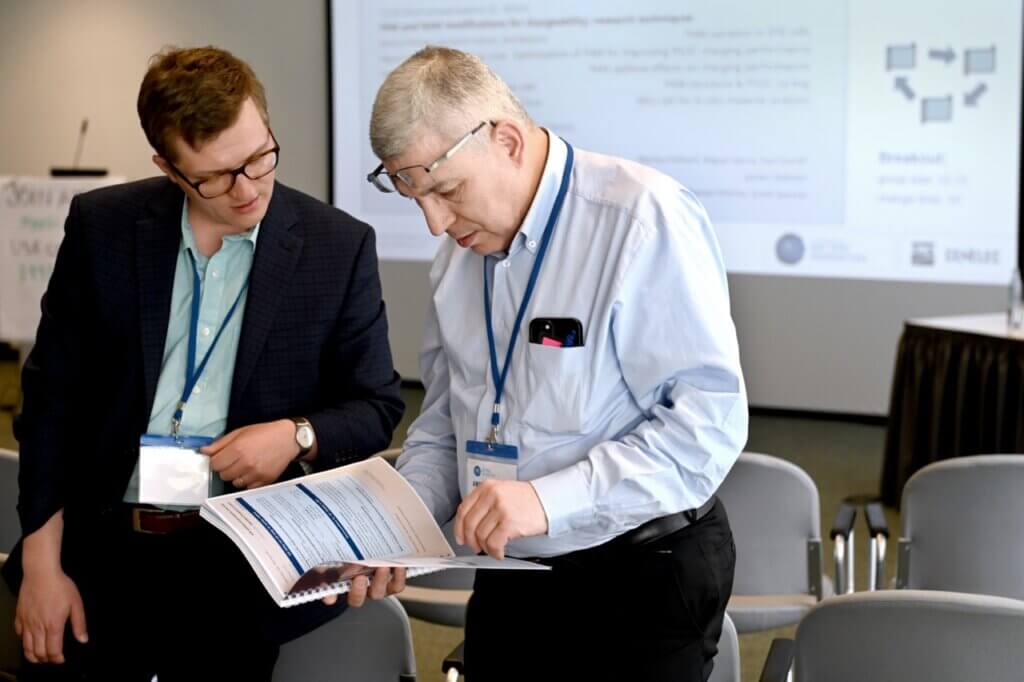

The CBI 2023 Techincal and ALBA Workshops were held on June 13-15, in Wolfsburg, Germany.

A solar and lead battery-powered tractor, that is being developed as a farming solution for Africa, was named a semifinalist for the Milken–Motsepe Prize in Green Energy. The competition rewards projects who expand access to reliable, affordable, and sustainable electricity in Africa.

AfTrak or Africa Tractor, is a prototype program funded by Innovate UK as part of its Energy Catalyst Round 9. The program was one of 20 teams selected to advance to the Semifinalist Round for a competition by the Milken Institute and the Motsepe Foundation. Semifinalists receive $20,000 for the continued development and testing of their designs, as well as complimentary access to a Stanford Online course to help build their businesses.

AfTrak was selected from over 160 entrants around the world, in over 36 countries.

This potentially revolutionary tractor design, featuring lead batteries, is an African farming project created in collaboration between the Consortium for Battery Innovation (CBI), UK- & Malawi-based charity Tiyeni, and Loughborough University.

“We are delighted to be selected as a semifinalist in this prestigious competition—a reflection of the inspiration and technical capabilities of the Loughborough and Tiyeni teams. It’s also a great indicator of CBI’s ambitions.” said Carl Telford, Senior R&I Manager at CBI.

Across large areas of Malawi, under the few inches of topsoil, there is a heavily compacted layer of rock-hard earth through which plants cannot penetrate. Tiyeni has created an innovative agricultural method called Deep Bed Farming (DBF). The tractor, being developed at Loughborough University, will be a low-cost, hand-operated, solution for farming in the difficult soil.

The proposed AfTrak project is a micro electric tractor capable of mechanizing land preparation in line with Tiyeni’s Deep Bed Farming to prepare soil to a depth of 400mm.

For this program, AfTrak aims to provide an affordable green energy solution in sub-Saharan Africa, utilize a solar array and lead battery system to power micro electric tractors for Deep Bed Farming, and create a self-sustaining model for decentralized energy access.

An independent panel of expert judges determined the 20 teams receiving funding. Moving forward in the competition involves semifinalist teams demonstrating the effectiveness of their ideas in field tests.

They will be evaluated for their ability to:

After the Semifinalist Round, judges will select five finalist teams to conduct another round of field tests in Africa. Then in May 2024, the judges will award a $1 million Grand Prize. A Runner-Up Prize of $250,000 will also be awarded.

The Milken Institute is a nonprofit, nonpartisan think tank focused on accelerating measurable progress. They bring together the best ideas and innovative resourcing to develop blueprints for tackling critical global issues.

The Milken–Motsepe Innovation Prize program is a series of multiyear, multimillion-dollar innovation competitions for technological solutions that accelerate progress toward the UN Sustainable Development Goals (SDGs).

One of the two innovation competitions in the program, the Milken–Motsepe Prize in Green Energy, aims to expand access to reliable, affordable, and sustainable electricity in Africa as an essential factor in achieving long-term economic growth and shared prosperity. The competition advances progress toward SDG 7 (ensuring access to affordable, reliable, sustainable, and modern energy for all).

The semi-finalists were announced on June 6, 2023.

More information:

NOTE: AfTrak is the second bid application to be awarded to CBI in the past year after LoCEL-H2, a sustainable microgrid project using lead batteries and a novel, lead-battery-enabled funded by the European Commission under the Horizon Europe program.

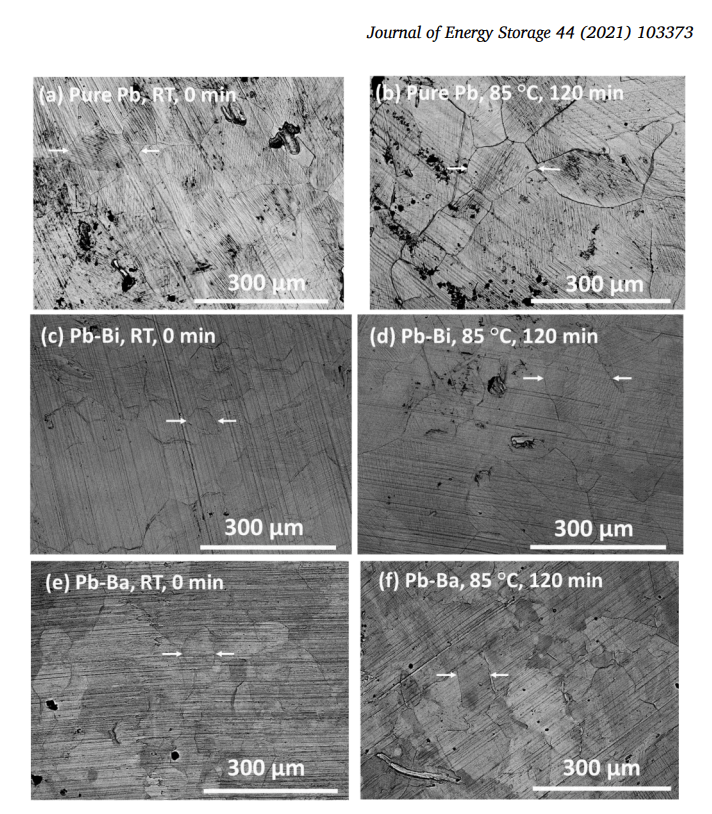

CBI spoke to Marcus Young, an Associate Professor and Associate Department Chair for the Undergraduate Program at the University of North Texas (UNT) about a two-year project that kicked off in February 2023 to look at materials in low voltage (12V) batteries for electric vehicles in an effort to further improve performance of lead batteries.

Lead batteries are still used in virtually every car on the road-from combustion engine vehicles through to Electric vehicles. Working alongside UNT, East Penn Manufacturing Company, and ECOBAT, CBI will further study the 12V battery electrochemical processes for materials and duty cycles common for lead batteries used in electric vehicles. By understanding more of how these batteries function in different charge conditions, temperature, and climate, we can determine what changes will attain a longer life span and better performance.

Electric vehicles rely on lead batteries to provide safety functionality in the case of failure of the main propulsion battery. This application is referred to as low voltage or auxiliary battery functionality. The lead batteries used in low-voltage EV applications use advanced alloys with different metallic additives to achieve current levels of performance. The study will focus on two specific additives, Ba (barium) and Bi (bismuth), and how their grain structure and influences on corrosion rates and crystallization would affect grid performance in the conditions found in EVs Previous research has shown that grids with Ba additives have reduced oxide formation, while Bi facilitates faster recrystallization.

Using XRM – or X-ray microscopy, this project will investigate corrosion in batteries and look at the impact of Ba or Bi additives on battery life. The technique requires relatively thin samples to be used. Extremely thin pieces have been created and used on the nano scale, so that they can be x-rayed. As the x-ray penetrates through these panels, researchers will isolate areas of interest and study the impact of aging time to see a source(s) of potential problems.

Beyond lab-scale techniques, synchrotron experiments at the APS at Argonne National Laboratory will be used on large samples linking lab findings to real world lead battery products used in auxiliary applications.

“We’re making battery life better for everyone,” said Young. He explained that ultimately this research will impact daily users as the battery storage community creates faster, better, and more efficient sources.

Planning is Underway for LoCEL-H2, a Four-Year, €10million Sustainable Energy Storage Project, Co-funded by the European Union

[LE BOURGET-DU-LAC, February, 2023] – A recently won European Union project by the Consortium for Battery Innovation (CBI) will pair advanced lead batteries with green hydrogen to deliver a new source of clean, reliable, and sustainable energy storage for off-grid communities in Africa.Awarded through Horizon Europe, this collaborative, four-year project called LoCEL-H2, (or Low-cost, Circular, plug & play, Off-grid Energy for remote Locations including Hydrogen), combines the expertise of lead battery manufacturers, academia, national laboratories, component manufacturers, and companies who are focused on integration, microgrids and renewables.

LoCEL-H2 will generate renewable energy, storage, and fuel for deployment in isolated and remote regions of Africa, to support communities that cannot connect to an electricity grid.

“The excitement around this innovative project is reflected by everyone involved,” said Dr. Carl Telford, the senior research and innovation manager at CBI. “Energy poverty is a problem that affects millions of people worldwide because they lack consistent access to electricity.”

The majority of the world’s population living in energy poverty are in Sub-Saharan Africa and are dependent on traditional stoves and fuels for their cooking. As a result, most of the domestic chores are handled by the women in these households, who then develop an increased health risk from a constant exposure to biomass, kerosene and/or coal fuels used for cooking.

The LoCEL-H2 project will provide a sustainable energy source as well as access to clean fuels. Another benefit will result in the education levels within these communities being positively impacted since they will now have access to online information through a reliable energy connection.

“This project is important to help address the United Nations Sustainable Development Goal 7 (Affordable and Clean Energy), while having an impact on other areas such as health,” noted Dani Strictland, professor of electrical power engineering at Loughborough University and a member of the LoCEL-H2 partnership.

This project involves nine partner companies across western Europe who will develop new technology for a novel distributed microgrid, as well as a Battolyser. The Battolyser is a new solution for producing clean hydrogen technology to power cooking surfaces and would replace biomass fueled stoves.

Whether as a response to climate impacts or future energy storage needs, advanced lead batteries are often an overlooked and innovative technology that bring safe, reliable, low-cost solutions to pair with a renewable source.

By combining lead batteries with wind and solar power, this forward-looking energy storage project will deliver ongoing, affordable electricity to off-grid communities and become a deployable solution for other energy-deprived areas around the globe.

The two pilot areas for the project will be focused in Zambia and Ivory Coast. Angel Kirchev, a senior expert, Ph.D., HDR, at CEA Tech and LoCEL-H2’s project coordinator said, “CEA looks forward to coordinating this exciting and challenging 4-year project which will bring sustainable energy and green hydrogen to challenged communities.”

Watch our LoCEL-H2 Kick-Off Video here.

![]() Project Co-Funded by the European Union

Project Co-Funded by the European Union

The members of the partnership are CEA, Hoppecke, Hollingsworth & Vose, UNINA, Loughborough University, Sunkofa, University of Gabes, SAS Réseaux Hydrogène Décarboné RHYDE, and LUMS.

Contact: Lara Wilson

CBI Sr. Communications Manager

Lara.wilson@batteryinnovation.org

About Consortium for Battery Innovation

The Consortium for Battery Innovation (CBI) is the world’s only global pre-competitive research organization funding research into lead batteries for energy storage, motive, and automotive applications. For more than 25 years, with its global membership of battery manufacturers, industry suppliers, research institutes, and universities, CBI has delivered cutting-edge research pushing the boundaries of innovation in lead battery technology, setting the standard for advanced lead batteries and the next generation of energy storage.

For more information, visit our website: batteryinnovation.org

About Loughborough University

Loughborough University is the home of world leading engineering, with an international reputation for being at the forefront of technological innovation and for maintaining extensive links with industry. The Wolfson School of Mechanical, Electrical and Manufacturing Engineering is one of the biggest engineering schools of its kind in the UK. The school aims to provide international leadership in research and innovation with a focus on climate change and net zero and has an unrivalled educational experience. Loughborough University is consistently in the top 10 in many university ranking tables for student experience.

Learn more at lboro.ac.uk/departments/meme/.

###

In January, a few members of CBI’s team visited eastern Pennsylvania to tour part of East Penn Manufacturing’s facility which produces over 500 types of batteries, including a large number of lead battery designs. Indeed, East Penn produces gigawatt hours of batteries every year – and is a real-world, established gigafactory.

Norbert Maleschitz, East Penn’s Executive Vice President & Chief Operating Officer, shared his excitement about the future of lead batteries. With innovation as part of their DNA, he explained that East Penn is pushing its technology further through an ongoing investment into R&D and Engineering. As lead batteries’ role in meeting future energy demands grows, Maleschitz and East Penn support improvements in manufacturing because they are key for enhancing technical solutions to both customers and the industry.

Dr. Matt Raiford, CBI’s Senior Technical Manager, inquired about the projects and enhancements underway at East Penn. There are several activities focused on improving electrode design, material innovations, and overall battery designs. The results will be a key part in continued performance improvements for lead battery technology and vital for ensuring that these batteries can meet future energy storage requirements.

CBI also had the chance to discuss and view some ongoing project work at the Briedegam-Miksiewicz Innovation Center R & D Department. Dr. Carl Telford, CBI’s Senior Research and Innovation Manager, met with Perry Kramer, Director of Technology, Research and Development at the Center and was able to look at how they are working with New Zealand-based development partner, ArcActive, to fully take advantage of the development of this novel technology.

Perry explained how ArcActive Technology features a carbon felt that replaces the standard lead grid structure of the negative current collector, enabling significant increases in charge acceptance. A battery featuring this technology helps to lower emissions in micro hybrid vehicle applications, and also improves the charging characteristics of the traditional 12 V lead batteries used in electric vehicles (these ‘auxiliary’ batteries power a vehicle’s accessories and critical safety functions).

Perry shared an overview of another large project that is focused on increasing cycle life. Bi-polar battery technology offers the potential to increase cycle life by three times over standard Absorbed Glass Mat (AGM) products while also reducing weight. The applications of this technology could range from use in automotive to reserve power and motive power, as well as other energy storage applications.

Telford and the rest of the team were particularly interested in East Penn’s work related to future manufacturing processes for lead batteries. Manufacturing needs to be very precise and predictable to enable the construction of a commercially successful, reliable, and dependable lead-battery product. East Penn has a large capability in manufacturing engineering and automation. Further innovations in manufacturing will provide the right mechanisms for extending battery longevity in future applications.

Finally, the team toured East Penn’s smelter and recycling facility. Lead batteries are a fantastic example of a product designed for complete end of life recycling, and currently over 99% of lead batteries are collected and recycled in North America. Their facility recycles everything including the acid. The facility recycles 182 million pounds of lead on an annual basis. In addition, they have a process in place to remove nitrogen oxide exhaust or off-gases and use them to create other products that benefit an adjacent industry.

Overall, CBI greatly appreciated the tour of East Penn to learn how their facilities’ efforts and leadership truly make the lead battery such an important contributor to global energy storage and a model for a more circular economy.