Did you know that there is a lead battery in nearly every vehicle on the road today? Lead batteries are crucial for the automotive industry, with 12 V lead batteries being used for SLI (starting, lighting and ignition), start-stop and micro-hybrid applications. According to Avicenne Energy (CBI’s Market Report 2023), the 12 V lead battery market for automotive applications is expected to grow from US$ 16 Bn in 2020 to almost US$ 25 Bn in 2030.

The Consortium for Battery Innovation (CBI) contributes to the growing demand for high-performing lead batteries by funding pre-competitive research as part of our Technical Program, based on research priorities defined on CBI’s Technical Roadmap. For automotive applications, research focus is on the following performance metrics and electrochemical properties:

| Dynamic charge acceptance (DCA): the ability of a battery to accept instantaneous energy during charging | |

| Hydrogen evolution reaction (HER): the side reaction occurring on a negative electrode surface which accelerates water loss | |

| Cold cranking amperage (CCA): the high discharge pulse power responsible for starting a car, rated at -18 °C for 30 seconds | |

| High-temperature durability: the ability of a battery to perform at higher temperatures, measured by standardised overcharge tests typically above 60 °C |

In the project ‘Investigations on the effect of carbon surface functional groups on electrochemical behavior of lead-carbon electrodes’, finalised in March 2023, Fraunhofer Institute for Silicate Research and Wrocław University of Science and Technology have collaborated to investigate the influence of different types of carbon additives on the performance of negative electrodes in advanced lead batteries. The base of this study was the application of chemical modifications to two different amorphous carbons with low and high external surface areas to obtain a range of acidic and basic carbons for testing. Their key finding was that specific surface functional groups of carbon can increase DCA while lowering HER activity and improving CCA.

Completed in September 2023, the project ‘Best practices of cell testing for EFB regarding DCA and high-temperature durability’ brough together four German partners – Technical University of Berlin, Fraunhofer Institute for Silicate Research, Moll Batterien and Ford Aachen – in a collaborative effort to establish improvements to laboratory test methods for 2V lead battery test cells during battery use in automotive applications. They have successfully defined best practices for measuring weight loss and electrolyte decomposition with 2V laboratory cells during standard tests, and for test cell design and sealing to account for the harsh conditions at high temperatures. These results provide guidance for better optimization of active material formulation for automotive batteries.

Lessons learned from previous projects about carbon surface functional groups and laboratory cells are not only relevant to 12 V lead batteries, but also for the growing use of lead batteries in auxiliary mode. Because of the nonstop evolution in automotive technology, auxiliary batteries have been increasingly employed for safety back-up and supply power to specific electronic features, being a significant opportunity for low-voltage lead battery systems.

Helping to build up that knowledge for this significant emerging market, one new project kicked off in 2023 focusing specifically on auxiliary automotive use. The project ‘In Situ Imaging and Phase Analysis of Live Cell Lead Battery Materials for Auxiliary Battery Cycling Regimes’ is investigating processes occurring at microscopic level during representative tests for auxiliary batteries to understand how positive and negative electrodes change during different charge conditions. This study will link laboratory findings to commercial lead battery products, having large potential to improve performance metrics of lead batteries used in auxiliary applications.

If you want to know more about the findings of pre-competitive research projects supported by CBI, the full detailing of results is available for CBI members.

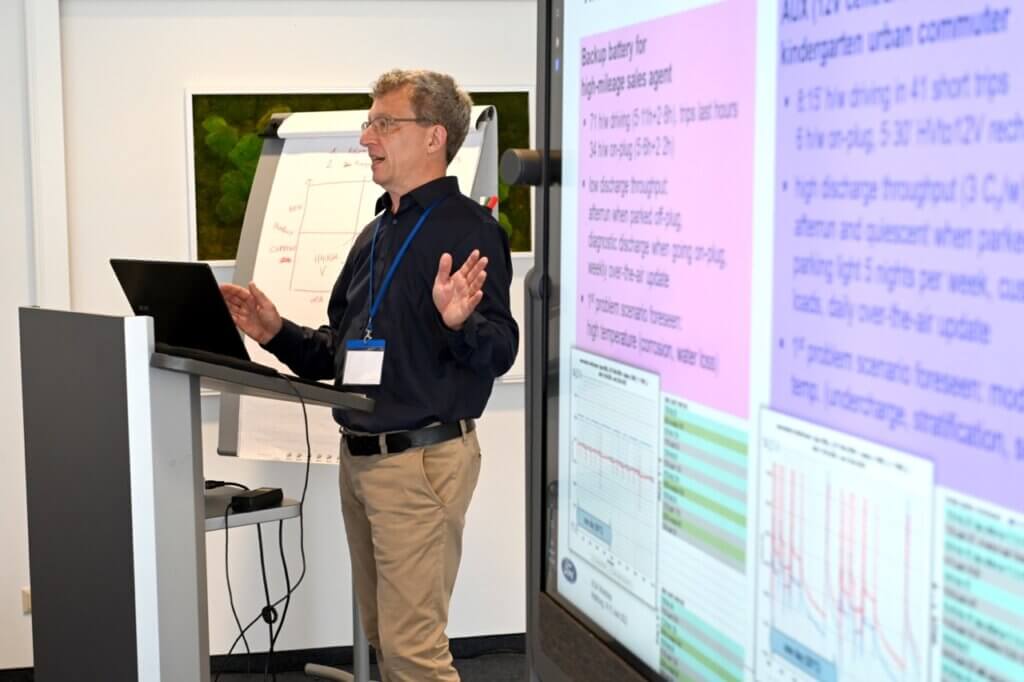

The CBI 2023 Techincal and ALBA Workshops were held on June 13-15, in Wolfsburg, Germany.

This European research collaboration aims to optimise lead battery performance for micro-hybrids. Researchers from Fraunhofer ISC and Wroclaw University are investigating the effect of carbon surface chemistry on the battery performance, and the goal is to understand which kind of surface chemistry is beneficial for improved charging and discharging behaviour for lead batteries.

Research projects like this one are proving to be relevant for wider scientific topics, such as low-emission vehicles, electrification and decarbonisation, as well as for carbon additive research.

According to Expert Group Manager from Fraunhofer ISC, Jochen Settelein, to follow the energy transition, batteries play a central role and lead batteries are safe, highly recyclable, produced at a low cost and the entire value chain exists within single countries or regions. By undertaking research and innovation into the lead battery technology, researchers are finding their way to adapt this « well-established technology » to the needs and requirements of the current energy transition.

Through this specific project, CBI is bringing together leading European researchers, scientists, and institutions to work towards a common goal, achieving CBI’s Technical Roadmap goals for the automotive sector, such as improving DCA.

Watch full video about this project here:

As part of CBI’s technical team, we’ve recently welcomed Begüm Bozkaya. With a BSc degree in Chemistry from the Middle East Technical University and an MSc degree in Materials Science from the Technical University of Munich, she gained extensive knowledge on the effects of carbon additives on negative plates for lead batteries, after using this as a Ph.D. research topic.

After working on several industrial projects for the past 6 years, Begüm joined CBI to gain a broader perspective on lead battery research as her role involves directly working with CBI’s global members from different companies and stages of the supply chain. She will be managing all of CBI’s European Technical projects as well as supporting CBI’s standards program.

According to her, CBI is doing what no one else in the industry is by “combining the knowledge from the industry and research institutes and collecting them in a non-competitive environment”. This means it’s possible to pool knowledge from a range of battery experts in order to advance lead battery technology for all applications, from energy storage systems to automotive.

As part of CBI’s team based in Europe, it is also important to look at the role of EU industry-research-academia partnerships in driving innovation. “We need to strongly defend the place of lead batteries. This is a well-established technology: we are cost-effective, recyclable, we have innovative research initiatives underway, and we’re committed to contributing to a cleaner future in the energy sector, especially to facilitate decarbonisation and support climate goals. It is vital that the EU includes all batteries in their future work plans”.

In that sense, the work developed by CBI through its Technical Roadmap has been essential to collect relevant information for lead battery applications and to help educate the audience regarding the future of this technology that has an enormous potential:

“If we can open new research topics and innovative ideas that can cover what we have in the roadmap, I’m sure lead batteries can still be considered a key player in the efforts to decarbonise, and developed further as a result. Research is the key point.”

When mentioning the new year and the developments that we can expect from advanced lead batteries, Bozkaya said that bipolar or advanced PbC batteries “can bring new research topics” for the industry and that these are “great candidates for EU initiatives”:

“There’s a bright future for advanced lead batteries and a lot of great research projects being developed as a result of CBI’s work, so I believe that in the near future we will be able to show even more how committed the industry is to Europe’s climate goals and, therefore be more involved with EU initiatives through lead battery research projects”.

For more information on CBI’s innovative technical program, click here.