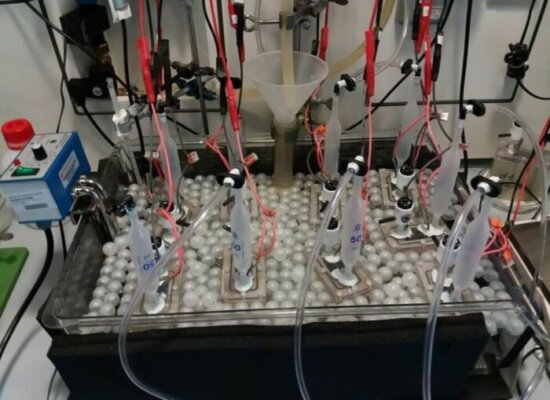

2019 project TUB, Fraunhofer ISC, Moll & Ford

Best Practices of Cell Testing for EFB regarding DCA and High-Temperature Durability

Partners

Technical University of Berlin, Fraunhofer ISC, Moll Batterien and Ford Aachen (Germany)

Duration

August 2020 - September 2023

Objective

This project aimed to improve laboratory test methods for 2V lead cells to investigate key parameters for automotive applications: high-temperature durability and water loss

Download the full summary

Research priority

Improve high-temperature durability and develop best practices for cell testing

See KPIs in our Technical Roadmap

Final results

• Best practices for measuring weight loss and electrolyte decomposition with 2V laboratory test cells during European Norm water consumption test 1 (EN 50342-1) and during new key-life test (nKLT) 2 were established.

• Best practices regarding test cell design and sealing to account for the harsh conditions at high temperatures were provided

• Impedance measurements provide some insight into dynamic charge acceptance (DCA) 3

• Results from 2V 5Ah small cells (Fraunhofer ISC) match with 2V 20 Ah commercial sized cells (TUB) and 12V commercial batteries regarding water loss and high-temperature durability tests

1 EN water consumption test: steady state overcharge test at 60 °C for 21 days

2 nKLT: High-temperature endurance test at 75°C for 28 days

3 DCA: the ability of a battery to accept instantaneous energy during charging

Impact

This research project has provided guidance for the methodology of laboratory cells and demonstrated that it yields more realistic results when comparing to the performance of commercial sized cells and batteries, which is important to optimize active material formulation for automotive battery applications

Contact us