ORLANDO, FL — April 29, 2025 Battcon, organized by the Consortium for Battery Innovation (CBI), is the industry’s benchmark event for real-world application training and the latest critical developments in stationary battery systems. Today, Battcon announced that the IEEE Power & Energy Society (PES) will be the technical co-sponsor for its 2025 event. This marks the first technical co-sponsorship between Battcon and the IEEE Power & Energy Society, expanding the conference’s global reach and technical impact.

Scheduled for Aug. 3–6, 2025, in Orlando, Florida, Battcon brings together engineers, operators, manufacturers and end users to address critical challenges in backup power systems for many different markets like data centers, energy storage systems, utilities, and telecommunications. With IEEE PES involvement, Battcon 2025 will be included on the IEEE Conference Search/Call for Papers website, and conference materials will be eligible for archival in IEEE Xplore®, expanding access to speaker research and technical findings across the global energy community.

“The involvement of IEEE PES as a technical co-sponsor enhances the already outstanding technical content at Battcon 2025,” said Dr. Matt Raiford, senior technical director of the Consortium for Battery Innovation. “Their role in co-publishing and archiving the conference’s peer-reviewed technical papers ensures that our speakers’ contributions are preserved and shared with a global network of power and energy professionals. This partnership strengthens the value of Battcon as a platform for advancing real-world battery applications in critical infrastructure.”

The IEEE Power & Energy Society, the world’s leading forum for electric power and energy innovation, has more than 42,000 members worldwide. Their participation furthers Battcon’s mission to deliver top-tier technical education and drive advancements across grid storage, telecom backup and data center UPS systems.

Battcon, organized by the Consortium for Battery Innovation (CBI), is where technical expertise meets real-world application. The 2025 event will feature expert-led sessions, pre- and post-conference workshops, an expanded expo, and targeted networking receptions connecting professionals across the stationary battery community. In Battcon’s uniquely independent exhibit hall, attendees can engage directly with leading manufacturers, suppliers and service providers. Learn more at www.battcon.com.

From a speech by Dr Carl Telford at the European Parliament in Brussels

As the Consortium for Battery Innovation’s name implies, my work places me in the middle of European energy storage activity. I work with large battery companies, universities, and put exciting project together. CBI’s core research aims at improving the capabilities of advanced lead batteries – but we are also technology agnostic and are extending our research to include other battery chemistries. Not just lithium, but sodium, zinc, redox flow, and perhaps technologies that are hitherto unknown.

The key thing is, we recognise the role of all these technologies in enabling energy security, decarbonisation, and affordable energy provision.

The European energy storage industry is already an impressive space. From Germany, to Portugal, Italy, Bulgaria and more – I have travelled and visited advanced lead battery manufacturing facilities across the continent. Combined, we have a pan-European multi-gigawatt production capability at our fingertips. Today. These batteries are used in a wide variety of mission-critical applications, not just car batteries but also renewable energy systems, backup power, peak shaving, nuclear power plant operation, and defence applications such as tanks or submarines. They are a critical to European security and a key piece in the jigsaw puzzle that is the Clean Industrial Deal and the Affordable Energy Action Plan.

I recently visited a European factory, and as part of a factory tour, I was shown a battery about the size of a large box. It was a metre high . A rather anonymous looking thing. But without this box, you could not operate a nuclear power plant safely. A big battery, with an even bigger responsibility.

In most of these factories, old batteries come in at one end, and new batteries come out the other end. The lead battery industry is a closed loop. This is not only a good thing from a circularity perspective, but also from cost and energy-security perspectives. These are batteries whose raw materials are all freely available in Europe, with zero reliance on expensive difficult-to-source materials.

A lot of the work I do relates to renewable energy and energy storage systems or ESS for short. The ESS market is growing rapidly. A recent report by KPMG noted that the European market for ESS will approach 200GWh-per-year by 2035, and lead batteries have the potential to supply an important chunk of this, around 10-15GWh-per-year. CBI recently visited the Isle of Eigg, off the Northwest coast of Scotland. This community relies on a microgrid with an advanced lead-battery storage system to provide affordable electricity. You see the same story across the world, from Africa to Antarctica. We make tough, cost-effective batteries for challenging environments.

Our industry also conducts cutting edge research, which doesn’t always fall under the spotlight. I’ve put together a microgrid project for Horizon Europe which features a battery that, when fully charged, becomes an electrolyser, producing hydrogen. You don’t run out of storage, you just transition to another energy vector. Electrons to gas. This technology – called a battery-electrolyser or battolyser – is a European invention, developed in the Netherlands and the UK.

Another project we co-founded is called Aftrak. It combines a small, low-cost electric tractor, a scalable solar microgrid, and a novel agricultural technique. The tractor enables African farmers to increase their yields, sell surplus crops, and lift themselves out of subsistence. It is electrical and economic empowerment. I have seen this project grow from an idea on a scrap of paper in a hotel in Malawi, to a government-funded project, to an international prize winner, to a startup company, in 3 years.

These exciting projects would not be possible without the brilliant University scientists, imaginative startups, and determined, practical and supportive lead-battery manufacturers we have at our disposal in Europe.

We must not take them for granted; there is much more we can do.

My message to decision-makers in Europe is this:

Thank you.

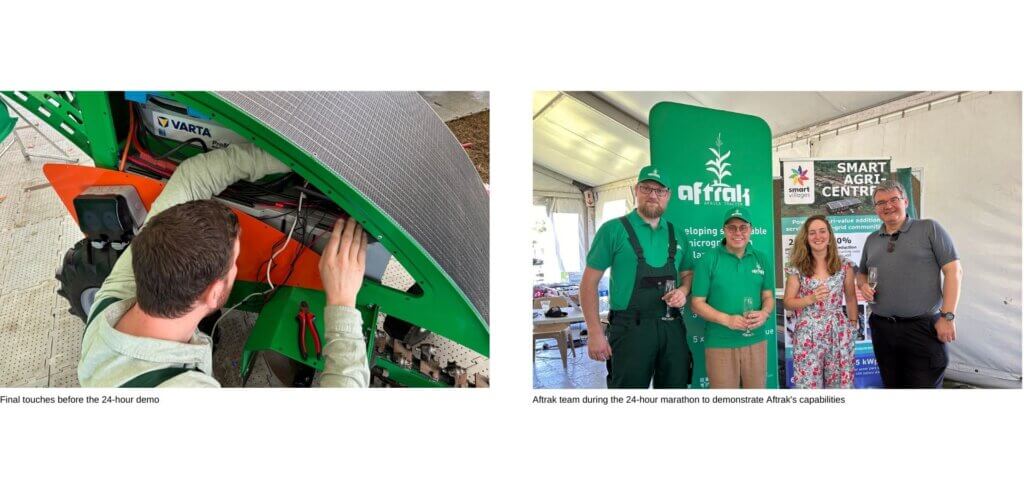

Aftrak is an innovative project combining solar microgrids and tailored tractors to empower smallholder farmers across Africa. In this interview, Dr. Carl Telford, CBI's Research & Innovation Director, talks about his trip to South Africa to demonstrate Aftrak's capabilities and their exciting journey as finalists for the Milken-Motsepe Prize in Green Energy.

Could you start by telling us a bit about Aftrak? What are you aiming to achieve with this initiative?

Aftrak is more than just a tractor. It's a complete ecosystem where agriculture boosts energy provision, and that energy revolutionises how we farm, leading to economic empowerment. It all started with Jonathan Wilson getting the idea for Aftrak in a hotel bar in Malawi during an Innovate UK field trip about 18 months ago.

Since then, we've secured over £300,000 in funding, designed and built two innovative tractors, and created a smart solar array to power them, all using green energy and recyclable materials. These tractors are easy to assemble and self-propelling, making them accessible to just about anyone. Plus, they use standard 12V truck batteries, so they can also power other essential devices like fridges and lights.

Aftrak made it as a finalist for the Milken-Motsepe Prize in Green Energy. How did you feel when you got the news? What could this mean for the project moving forward?

I was absolutely overjoyed but also a bit torn. On one hand, I couldn't believe we'd made it to the finals of such a prestigious competition. On the other hand, given all the innovation and hard work we've put in, I felt it was well-deserved. Being a finalist is a major achievement and opens up opportunities to expand and potentially create a whole new sector if we win!

24 hours of innovation

In February, you went to South Africa to demonstrate Aftrak's capabilities. Before heading to South Africa, what were you hoping to accomplish with the demo?

Our first goal was to have all the systems up and running smoothly. The team from Loughborough did an amazing job in this regard. Just getting the units shipped was hard enough in a short time. It was a real challenge, but seeing it all come together and work was just incredible.

How did people react to Aftrak, and what kind of feedback did you get right off the bat?

The response we received was overwhelmingly positive. People were impressed by our team's professionalism and how well everything was set up. They also seemed curious about the Aftrak unit itself, asking what it was, which led us to hold a few mini-training sessions. The Solar Array, in particular, got a lot of attention, with several attendees asking about purchasing it!

You and the team pulled off a 24-hour demo marathon. How did it go, and what were some standout moments?

The 24-hour demo was all about proving that our system could reliably generate 90kW/h of electricity. We exceeded those expectations, which was fantastic. We also wanted to prove the tractor worked. So we got it to dig in a sand pit and power a chest freezer and a tea urn. One funny moment was during the night when we could monitor energy usage and tell the exact time when the security team was making tea!

Redefining farming strategies

Deep bed farming is central to Aftrak's strategy. Can you tell us about this method and the difference it makes for the farmers and communities?

In some parts of Africa, a hard layer beneath the soil stops water and roots from penetrating, which is terrible for farming. Our partner Tiyeni developed Deep Bed Farming, which is a proven method that breaks up this layer, increasing crop yields, reducing flooding, and providing additional revenue for smallholder farmers. This technique, however, requires a lot of manual labour. Unless you use an Aftrak unit, which can do it for you.

Trips like these always have their surprises. What was something unexpected that happened during your time in South Africa?

One of the most unexpected things was a sudden power outage during our setup, which is a huge issue in South Africa. At one point, the entire demo tent went dark! However, we quickly hooked up our tractor to the power supply, lighting up the tent again and allowing everyone to continue their preparations.

With the announcement just around the corner, how do you feel about Aftrak's chances?

It may sound like a cliche, but making it to the final five is the real achievement. Just getting on the stage at the Milken conference is already a win for me. I believe we have a chance, but I don't have any additional expectations from this point on. I don't think we could have done any more in terms of preparation, and I have confidence in the team going forward, whether we win or not. That's all I have to say!

Aftrak's vision for the future

Looking down the road, what's the big dream for Aftrak? Where do you see it going, and what kind of impact do you hope it'll keep having?

It's very straightforward. We want to provide access to energy, double crop yield, reduce flooding, and enable economic and literal empowerment for millions of people in sub-Saharan Africa. However, to achieve this, we have a lot of work ahead of us.

We need to establish a company or, at least, find some way of building it on a large scale. Additionally, we must ensure the system is affordable for end-users. Despite these major challenges, we have made huge progress in the last 18 months, and I believe these are achievable.

Among all the milestones Aftrak has achieved so far, is there one that stands out as a 'wow' moment for you? What made it so memorable?

There are two. The first was when I saw the Aftrak unit in person at Loughborough University, all set to ship out to South Africa. It made all of it seem real. The second moment was when I arrived at the demo site in Stellenbosch. There, I saw all the equipment being set up, and I also met the team from Malawi for the first time in person.

At that point, I remembered Jonathan's initial idea that we had discussed in the hotel bar. A lead-battery tractor? At that time, I told him he was crazy. But the more we explored the idea, the more it made sense. In Stellenbosch, after seeing the people and the technology, my belief in what we were doing took off like a rocket.

Uncovering the key role of energy storage in Europe's green revolution

As we step into a new year marked by record-breaking temperatures, the urgency to address climate change intensifies. A recent analysis has confirmed 2023 as the warmest year on record, with over 200 days setting new daily temperature records.

It is crucial that cities join the shared drive to mitigate the climate crisis and transition to greener, more sustainable energy. This was emphasised at COP28, where fossil fuels were officially recognised as the primary cause of climate change for the first time after 28 years. Within Europe, the European Commission is leading the way by introducing ambitious initiatives such as the Fit for 55 package and Effort Sharing Regulation to shift towards a low-carbon economy. These initiatives have sparked innovation and collaboration among European cities as they strive to embrace a more sustainable path.

The second part of our series on sustainable cities highlights the transformative efforts of three European cities – Helsinki, Ljubljana, and Sofia – in embracing energy storage to spearhead their sustainability goals. These cities serve as examples of how local governments can initiate a transition towards renewable energy, sustainable transportation, and emission reduction.

Embracing sustainable energy solutions

In the northern part of Europe, Helsinki is a pioneer in sustainability. The Finnish capital has embraced energy storage as a key element in achieving its goal of carbon neutrality by 2030. The city has launched an inventive project in collaboration with its energy provider to integrate battery energy storage into electric vehicle charging stations. The initiative taps into the potential of electric vehicles as mobile energy storage units, capable of storing excess energy generated from renewable sources. This energy can power the vehicles or be returned to the grid, making the energy ecosystem more connected and resilient.

According to the city's mayor, Juhana Vartianten, building a sustainable future is the most pressing issue we face today. "Helsinki wants to encourage cities around the world to embrace sustainability work and take concrete action. The coming years will determine the direction humanity takes, " said Vartiainen in the 2023 Voluntary Local Review, "That is why we must act now, and we must act together. We still have a long way to go, but fortunately, we are heading in the right direction."

Sofia, the vibrant capital of Bulgaria, is another city that has made sustainability a cornerstone of its urban development strategy. The city has implemented a number of innovative projects that are helping to reduce its reliance on fossil fuels and improve energy efficiency.

One of Sofia's most notable initiatives involves the installation of intelligent batteries throughout the city's public transportation network. These batteries act as mobile energy storage units, allowing buses and trams to store energy while braking or coasting downhill. The captured energy can then power the vehicles as they climb uphill or accelerate. This approach has shown promising results during its trial phase, with an expected 10-15% reduction in fuel usage and a 30% decrease in harmful carbon emissions, contributing to cleaner air and a more sustainable transportation system.

In addition to the environmental benefits, Sofia's battery storage project also streamlines the public transportation system, reducing the need for frequent recharging. The batteries provide a clean source of energy that can be used during peak hours, allowing passengers to rely on a more efficient public transportation system.

Harnessing the power of energy storage

Ljubljana, the capital of Slovenia, is known for its eco-friendliness and sustainable urban development. The city is taking steps to make its buildings sustainable while preserving its rich cultural heritage. One way Ljubljana is achieving this balance is by implementing energy storage systems in public buildings and infrastructure. The Ljubljana City Hall is equipped with a battery storage system that can store energy from the sun. Moreover, Ljubljana aims to expand its energy-saving efforts beyond City Hall by installing energy storage systems in public buildings such as schools, libraries, and other facilities.

Integrating energy storage systems into public buildings is a win-win solution for both cities and citizens. By doing so, the city enhances energy security, lowers energy expenses, and provides backup power during grid outages. This not only reduces the city's environmental footprint, but also provides its citizens with reliable access to energy.

In a world where climate change looms, Helsinki, Ljubljana, and Sofia are examples of how innovation and energy storage can shape a sustainable future. These cities have set the bar high by adopting measures that align with the EU's Green Deal goals, aiming to reduce carbon emissions and switch to renewable energy sources.

Helsinki's electric vehicle charging stations, Ljubljana's public buildings integrated with battery systems, and Sofia's intelligent battery storage for public transportation all show how technology can help create a cleaner, more resilient planet. By reducing carbon emissions and embracing renewable energy sources, these cities are leading the way in the fight against climate change.

Low-cost, Circular, plug & play, Off-grid Energy for remote Locations including Hydrogen

Funding: Horizon Europe

Duration: 1 January 2023 – 31 December 2026

Project partners: Consortium for Battery Innovation, Commissariat a l'Energie Atomique et aux Energies Alternatives, Hollingsworth & Vose, HOPPECKE Batteries, Lahore University of Management Sciences, Loughborough University, RHYDE, Sunkofa Energy, Università degli Studi di Napoli Federico II, University of Gabes

LoCEL-H2 (Low-cost, Circular, plug & play, Off-grid Energy for remote Locations including Hydrogen) is developing a new solution to bring renewable electricity and clean cooking fuel for off-grid communities.

The solution comprises three core technical innovations:

LoCEL-H2 will conduct two pilot programs, one located in Zambia and the other in Côte d’Ivoire, assessing each community’s energy needs and tailoring the solution in order to provide renewable energy and cooking fuel for approximately 30 households and businesses in each pilot.

For more information visit project's website: https://locelh2.org/

New Report Reveals How Lead Batteries are Featured in Chinese Energy Storage Systems

As the global power industry wrestles with the need to expand energy storage to accommodate renewable generation and meet soaring demand for electricity overall, a new CHR Metals Limited report states that countries like China are shifting some focus toward lead batteries over lithium for battery energy storage systems.

“The growth of lead battery energy storage systems in Asia, especially in China, is promising, driven by efforts to reduce fossil fuel use and achieve net-zero goals,” said Dr. Alistair Davidson, director of the Consortium for Battery Innovation. “With the energy storage market expected to exceed 400 GW by 2030, the CHR Metals analysis highlights significant opportunities for lead battery projects regionally and globally.”

Currently, only lithium-ion and lead batteries operate on a scale sufficient to meet demand, representing over 98 percent of the rechargeable battery market through 2030.

Lead batteries, known for their efficiency and reliability, continue to play a vital role in backup power for critical infrastructure, hybrid automotive, and motive power applications. Advanced lead batteries emerge as an ideal solution for energy storage, boasting superior performance, safety, and scalability to align with the U.S. and E.U.'s net-zero emission goals for 2050.

This week’s CHR Metals Limited Report also notes:

Contrary to misconceptions, lead batteries stand out as the most recycled and innovative products globally, minimizing the carbon footprint by utilizing recycled materials. Over 97 percent of lead batteries in North America and Europe are collected and recycled, with 85 percent of the recycled lead used in manufacturing new batteries—a testament to the circular economy in action. (Source: Association of Battery Recyclers)

Lead batteries can help deliver on climate-neutral pledges and provide energy resiliency in specific applications.

“Despite ongoing misconceptions, ongoing research and innovation have propelled advanced lead batteries to impressive strides in performance over the past decade,” added Davidson. “These advancements, including improved cycle life, lifetime, and overall energy efficiency, translate into substantial benefits in terms of total cost of ownership and reliability.”

While embracing an overall diversification of energy sources and plans to increase renewables, the versatility and proven performance of advanced lead batteries position them as a scalable and cost-effective solution to meet today's demands and future energy storage needs.

September 26, 2023

By Alyssa McQuilling

The Electric Power Research Institute’s (EPRI) Energy Storage Integration Council (ESIC) held a Strategy Meeting on September 14, 2023 at the JW Marriott in Indianapolis to focus on identifying the energy storage gaps and how ESIC can address them.

The mission of ESIC is to advance the deployment and integration of energy storage systems through open, technical collaboration.

This meeting was open to the technical community of energy storage stakeholders, such as electric utilities, energy storage developers and integrators, regulators, system operators, independent power producers, and research and consulting organizations.

As the technical voice of the lead battery industry, CBI sent US Research and Innovation Manager, Dr. Alyssa McQuilling, to share and collaborate on industry insights.

Her takeaways from the event included:

Lastly, the six national labs have to a role to play in getting emerging technologies ‘over the hump’ in terms of development. This includes those opportunities created through Grid Storage Launchpad and ROVI (Rapid Operational Validation Initiative).

We look forward to seeing CBI’s members transform projects into products that can benefit industry and utilities in meeting their renewable integration and decarbonization goals.

The European Energy Transition

By Nicola Filizola

As the world copes with the urgent need to address climate change and reduce greenhouse gas emissions, Europe has been leading the charge in transitioning to a cleaner and more sustainable energy future. The European energy transition is a comprehensive shift from traditional fossil fuels to renewable energy sources, such as wind, solar, hydro, and geothermal power. Among the critical components enabling this transformation, lead batteries have emerged as a key technology that plays a pivotal role in the transition's success. In this article, we will explore the energy transition in Europe and delve into the essential role that batteries are playing in shaping the continent's greener and brighter future.

The Growth of Renewable Energy in Europe

The European Union (EU) has been at the forefront of advocating for clean energy and sustainability. Through initiatives like the European Green Deal and the Paris Agreement, EU member states are committed to reducing their carbon emissions, fostering innovation in clean technologies, and achieving climate neutrality by 2050.

One of the main challenges of integrating renewable energy sources into the existing energy infrastructure is their intermittency. Solar and wind power, for instance, depend on weather conditions and daylight availability. To ensure a stable and reliable energy supply, an efficient energy storage system is essential, and that's where batteries come into the picture.

The Challenge of Intermittency

Unlike conventional power plants that can provide a consistent energy output, solar and wind power are dependent on weather conditions and natural variations. Cloudy days and calm winds can lead to a drop in power generation, causing fluctuations in the grid. This intermittency poses challenges to grid stability, and the power supply must be balanced in real-time to meet demand. If renewable energy sources are to dominate the energy mix, an effective and efficient energy storage solution is imperative to address this variability.

Batteries: The Key to Storing Renewable Energy

Batteries are essential components of the energy transition as they serve as a bridge between renewable energy generation and consumption. These energy storage systems can store surplus electricity when generation exceeds demand and release it when demand surpasses generation. In essence, batteries help to smooth out the intermittent nature of renewables and provide a stable supply of electricity to the grid.

Batteries act as buffers, absorbing excess energy during periods of high generation and releasing it when generation dips. By doing so, they stabilize the grid and ensure a steady supply of electricity, reducing the risk of blackouts and power disturbances. Moreover, batteries can respond rapidly to fluctuations in demand, providing grid operators with a valuable tool to manage the grid effectively.

The energy transition in Europe is also characterized by a shift towards decentralization, with an increasing number of small-scale renewable energy installations, such as rooftop solar panels and community wind farms. Batteries play a vital role in this decentralized energy landscape by enabling consumers to store and manage their locally generated energy. This promotes energy autonomy, reducing the reliance on centralized power plants and enhancing energy security.

Batteries make it possible to integrate a higher share of renewables into the grid. By storing excess energy during periods of high generation, batteries ensure that the energy is not wasted and can be used during times of low generation. This feature is particularly crucial during seasonal variations when renewable output may vary significantly.

Batteries also play a significant role in electrifying transportation, another essential aspect of the energy transition. The growth of electric vehicles (EVs) is dependent on advanced battery technology, allowing for longer driving ranges and faster charging times. Widespread EV adoption not only reduces greenhouse gas emissions from the transportation sector but also opens up the possibility of using EV batteries for grid storage through vehicle-to-grid (V2G) technology.

In conclusion

The energy transition in Europe represents a monumental effort to combat climate change and create a sustainable energy future. The integration of renewable energy sources is a crucial step in this journey, but their intermittent nature presents challenges that must be addressed. Lead batteries, together with other technologies, emerge as the silent protagonists, providing a robust and reliable energy storage solution. From enhancing grid stability and enabling renewable integration to empowering decentralized energy systems and fostering electric vehicle adoption, lead batteries will play a multifaceted role in reshaping Europe's energy landscape. As technology advances and costs continue to decline, the potential of batteries will only grow, propelling Europe towards a cleaner, greener, and more resilient energy future.

The lead battery industry could be in line for a $10 billion share of the burgeoning energy storage market within the next decade.

Research into upcoming projects and opportunities indicated that the ESS landscape is forecast to be 550GWh by 2030 with a value of $30-$50 billion for all battery technologies.

The lead battery industry has set its sights on securing 100GWh of that potentially lucrative ESS market.

CBI launched its first technical roadmap in 2019 setting specific goals for the end of 2022.

“It was all really market-driven. We used those targets to select our program. And the result of the

projects that we funded have pretty much shown that we delivered on these goals that we set.”

There are now batteries on the market, primarily from our members in the US and Asia, that meet that criteria.

This means there are now have advanced lead batteries on the market-oriented toward ESS that have an impressive globalized cost of ownership for the system, says Raiford.

“The way we view it as battery scientists is cycle life — most key stakeholders look at it from total cost of ownership.

“So we see stationary batteries now that really perform along the lines of lithium.”

Read the full article from Batteries International

22nd September 2023

The 7th World Energy Storage Day (WESD) Global Conference & Virtual Expo, 22nd September 2023 and is a virtual, 24-hour marathon conference covering 100+ countries including topics like Energy Storage Manufacturing, Innovation, Supply Chain, Mechanical Storage, Thermal Storage, Electro-Chemical Batteries, Energy Access, Stationary Energy Storage, Energy Storage Financing, Investment, ESS, EV infrastructure, Battery Swapping, Urban Air Mobility (UAM), EV OEMs, Battery Recycling, Circular Economy, Global Start-up showcase, Start-up workshop, Women in Energy and Green Hydrogen applications & Manufacturing.

The WESD platform is one of the largest open (Free to attend live) global events in this domain. The event is supported by Gold Partner UL and supporting Partner Green Hydrogen Organisation (GH2), MENA Energy Storage Alliance (MENA-ESA), Thailand Energy Storage Association (TESTA), Consortium of Battery Innovation (CBI), Eurobat, Smart Energy Council (SEC), Innovation Norway, Scotland Development International, LDES Council, Batteries European Partnership Association (BEPA), Global Renewables Alliance and others.

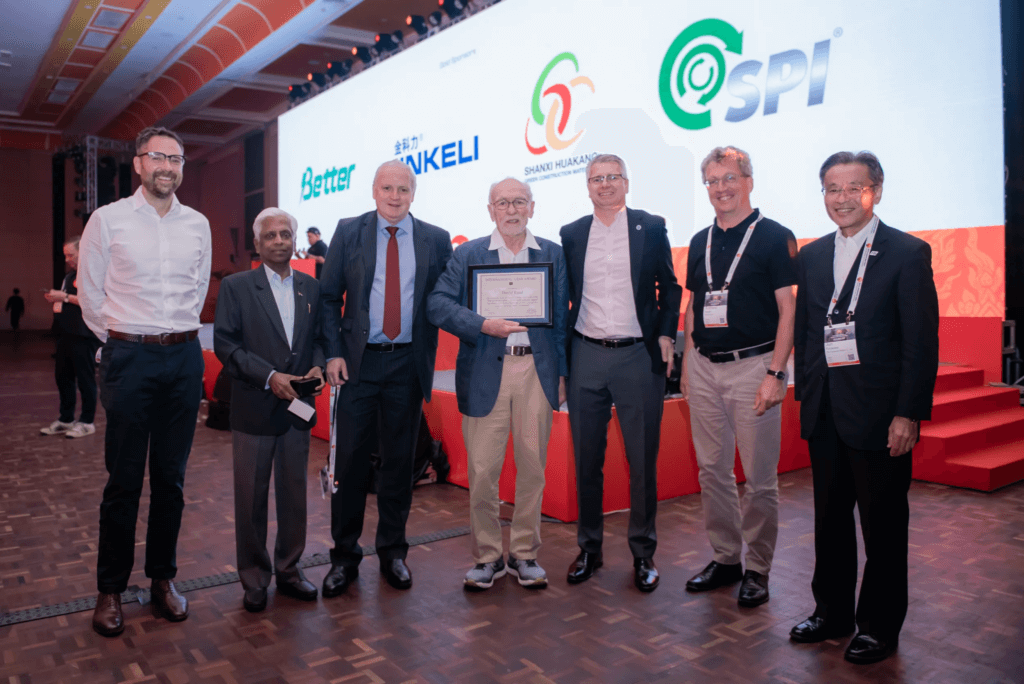

The Consortium for Battery Innovation connected with over 730 attendees from 42 different countries representing 319 different organizations in Siem Reap, Cambodia for the 20th Asian Battery Conference (20ABC) and the Recycle 100 International Secondary Lead Conference and Exhibition that featured global discussions on the world of lead, recycling, lead-acid batteries and energy storage.

CBI Senior Technical Manager, Dr. Matt Raiford said that lead batteries are made and produced in over 100 countries, and the Asian Battery Conference was a great venue to see how Asia, Africa, and other areas of the world are innovating and improving lead battery technology. For instance, CBI member companies, Hammond and Borregard, demonstrated deeper understandings of additive chemistry as a low threshold method to improve lead batteries for many different applications.

CBI participated in the line-up of over 45+ conference speakers during 20ABC to share our technical battery knowledge and insights with attendees with presentations that included:

The 20th Asian Battery Conference provided a chance to join several technical sessions providing valuable insights from industry leaders, market analysts and technical experts about the lead battery industry. Several speakers including CBI member companies presented innovations and advancements, such as new active material formulations and improvements in the manufacturing process, for several applications of lead batteries.

Dr. Begüm Bozkaya, CBI’s Technical Manager, shared that there are definitely future opportunities for lead battery technology in Asia and other continents of the world via the implementation of new developments to deliver cost-efficient, safe, and sustainable battery solutions.

8th International Secondary Lead & Battery Recycling Conference covered several aspects of lead recycling industry in Asia and Africa. Bozkaya shared that many of the speakers addressed the current issues related to environmental challenges, financial, and social risks in the secondary lead industry. It was beneficial for attendees as some of the ILA & CBI members also illustrated their new techniques and developments in recycling of lead batteries.

Recycle 100 illustrated the ins and outs of running battery recycling centers - the heart of lead battery sustainability. Raiford was intrigued by ongoing improvements at Asian recycling operations, especially in increasing recycling efficiency - and how these improvements were presented to representatives from dozens of countries.

The city of Siem Reap, Cambodia was an amazing host and we enjoyed seeing all the beautiful areas in that region. The 20ABC was a successful event from all angles – including the achievement from the event’s charity initiative. The "ONE Minute Giveback", exceeded organizer’s and sponsor Sorfin Yoshimura’s expectations, by raising over $22,000.00 USD to help fund a bed in the Oncology Department of Angkor Hospital for Children.

We look forward to next year’s events and continuing the technical conversations around lead batteries.

As part of the knowledge economy, individuals with a Ph.D. desire an in-depth knowledge within a specific field. To begin this journey, all Ph.D. or Doctor of Philosophy candidates must have very specific criteria to enter the doctoral program including a masters degree, letters of recommendation, and a statement of purpose that describes why they are seeking a PhD, what they have done so far to prepare themselves, and what goals they plan to achieve later.

For Begüm Bozkaya, her pursuit of a doctoral degree program was a way to explore advancements, provide more areas for career opportunity and continue to grow professionally.

Because of her appreciation in the study of electrochemistry during grad school that focused on batteries including Li-ion and carbon research, Fraunhofer Institute approached her about a position to work on advanced lead acid batteries. The opportunity was for more than just a Ph.D., as it was a complete package that involved a paid position on industrial projects. The program through Fraunhofer kept Bozkaya busy working on various carbon related industry projects, participating in networking and conferences, interacting with the lead battery industry, and of course spending time on her own studies.

“It’s important to network just as much as it is to allow time for your personal and social life,” Bozkaya said reflecting on her work-life balance. “You need to keep the bigger picture in mind. I recommend networking to help you widen your perspectives by meeting new people to collaborate with. During this time, she recommends shaping and structuring your thesis.

Bozkaya describes the path to her Ph.D. with a range of emotions and ultimately perseverance in overcoming a program that challenges you each day. She explained that there was a period toward the end of the program where her work was consuming, her ability to find focus time to write was limited, and she began to feel overwhelmed. She thought about quitting.

Instead, she found the motivation to keep going by just doing a little more each day.

“When you feel like you don’t want to continue in the program, give yourself one more push. You owe it to yourself. Then you will start to see how those little steps will move you forward. And the result will be rewarding.”

Her advice for anyone entering a doctoral program is to believe in yourself.

She warned that at some point you may start to feel overwhelmed for any number of reasons, and you might want to reconsider the research path. “That is the time to really lean into the support from your friends, family and colleagues,” encouraged Bozkaya.

That support and effort paid off and finally put her over the hump. And along with encouragement from both an old colleague and her family, Bozkaya could finally grasp her goal.

“The day of my defense was filled with emotion because of all the ups and downs it took to get this point,” said Bozkaya.

She completed her defense with an excellent score - a 1.0!

After an academic journey that started with a Bachelors in Chemistry, then a Masters of Materials Science, Begüm Bozkaya finally defended her Ph.D. thesis entitled, “Influence of Carbon Additives on the Electrochemical Performance of Modern Lead-Acid Batteries” on May 10, 2023.

Now Bozkaya continues her interest in materials science and batteries. In 2021, she was offered a role as Technical Manager for the Consortium for Battery Innovation. Bozkaya works with colleagues to secure EU funding projects and is responsible for CBI’s technical program in Europe – including workshops and conferences. Catch one of her presentations at an upcoming CBI conference and be sure to congratulate her on the new doctorate.

A solar and lead battery-powered tractor, that is being developed as a farming solution for Africa, was named a semifinalist for the Milken–Motsepe Prize in Green Energy. The competition rewards projects who expand access to reliable, affordable, and sustainable electricity in Africa.

AfTrak or Africa Tractor, is a prototype program funded by Innovate UK as part of its Energy Catalyst Round 9. The program was one of 20 teams selected to advance to the Semifinalist Round for a competition by the Milken Institute and the Motsepe Foundation. Semifinalists receive $20,000 for the continued development and testing of their designs, as well as complimentary access to a Stanford Online course to help build their businesses.

AfTrak was selected from over 160 entrants around the world, in over 36 countries.

This potentially revolutionary tractor design, featuring lead batteries, is an African farming project created in collaboration between the Consortium for Battery Innovation (CBI), UK- & Malawi-based charity Tiyeni, and Loughborough University.

“We are delighted to be selected as a semifinalist in this prestigious competition—a reflection of the inspiration and technical capabilities of the Loughborough and Tiyeni teams. It’s also a great indicator of CBI’s ambitions.” said Carl Telford, Senior R&I Manager at CBI.

Across large areas of Malawi, under the few inches of topsoil, there is a heavily compacted layer of rock-hard earth through which plants cannot penetrate. Tiyeni has created an innovative agricultural method called Deep Bed Farming (DBF). The tractor, being developed at Loughborough University, will be a low-cost, hand-operated, solution for farming in the difficult soil.

The proposed AfTrak project is a micro electric tractor capable of mechanizing land preparation in line with Tiyeni’s Deep Bed Farming to prepare soil to a depth of 400mm.

For this program, AfTrak aims to provide an affordable green energy solution in sub-Saharan Africa, utilize a solar array and lead battery system to power micro electric tractors for Deep Bed Farming, and create a self-sustaining model for decentralized energy access.

An independent panel of expert judges determined the 20 teams receiving funding. Moving forward in the competition involves semifinalist teams demonstrating the effectiveness of their ideas in field tests.

They will be evaluated for their ability to:

After the Semifinalist Round, judges will select five finalist teams to conduct another round of field tests in Africa. Then in May 2024, the judges will award a $1 million Grand Prize. A Runner-Up Prize of $250,000 will also be awarded.

The Milken Institute is a nonprofit, nonpartisan think tank focused on accelerating measurable progress. They bring together the best ideas and innovative resourcing to develop blueprints for tackling critical global issues.

The Milken–Motsepe Innovation Prize program is a series of multiyear, multimillion-dollar innovation competitions for technological solutions that accelerate progress toward the UN Sustainable Development Goals (SDGs).

One of the two innovation competitions in the program, the Milken–Motsepe Prize in Green Energy, aims to expand access to reliable, affordable, and sustainable electricity in Africa as an essential factor in achieving long-term economic growth and shared prosperity. The competition advances progress toward SDG 7 (ensuring access to affordable, reliable, sustainable, and modern energy for all).

The semi-finalists were announced on June 6, 2023.

More information:

NOTE: AfTrak is the second bid application to be awarded to CBI in the past year after LoCEL-H2, a sustainable microgrid project using lead batteries and a novel, lead-battery-enabled funded by the European Commission under the Horizon Europe program.

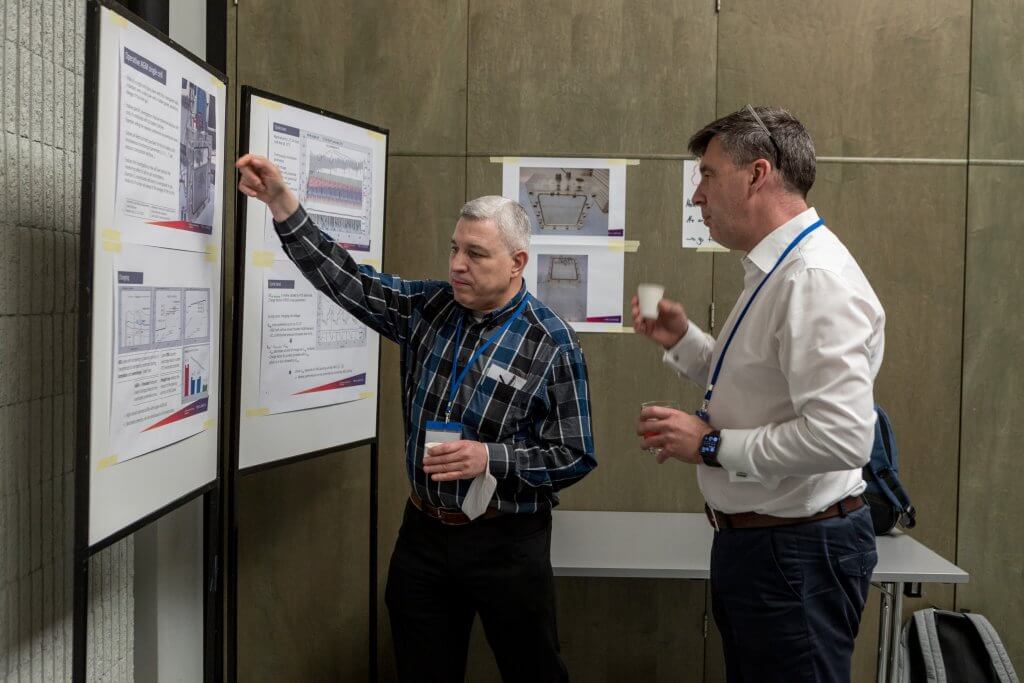

The Global Lead Battery Innovation Conference and Expo (ELBC), co-organised for the first time by CBI, took place in Lyon, France (6-9 Sept).

As a warm-up to the main conference, CBI brought together lead battery industry experts from all over the world, to take part in:

On day one of ELBC, CBI’s Director (Dr Alistair Davison) set out a positive assessment of the opportunities for advanced lead batteries highlighting CBI’s roadmap, which charts a path to a new generation of batteries in a session dedicated to Markets and Trends.

And CBI technical experts, including Begüm Bozkaya, Technical Manager, outlined the CBI technical program with an insightful presentation focusing on improving energy storage systems and automotive batteries as key innovations in the industry.

To promote CBI’s Technical Roadmap and its work in driving innovation across the industry Dr Matthew Raiford, CBI’s Senior Technical Manager updated delegates. And in a major announcement, Dr Carl Telford impressed ELBC attendees with news of a 10 million Euro funding award for an innovative lead-battery powered microgrid project in Africa, brokered by CBI.

In his presentation entitled « Opportunities for Lead Batteries in Energy Storage Systems », Dr Telford spoke about the use of lead batteries for sustainable energy projects and presented for the first time this novel project funded by the European Commission that gathers lead batteries, renewables, and hydrogen.

As always at ELBC there were many networking opportunities, with delegates able to meet face to face for the first time in four years. The well-attended gala dinner took place at La Sucrière, and WGBI’s (Women in the Global Battery Industry) held its first meeting in Europe. This important initiative aims to bring more women to our industry and empower them through networking sessions, workshops, and mentoring opportunities.

CBI is very much looking forward to seeing all these fantastic attendees and delegates again at ELBC 2024 in Milan, Italy.

Watch the Event video:

A ground-breaking new battery ‘match’ service is set to help utility companies choose the most suitable batteries as partners for their energy storage schemes.

CBI Battery Match has been designed and built by the Consortium for Battery Innovation (CBI) – the global advanced lead battery research group – to help electricity providers and other energy storage projects find a battery system that best meets their requirements.

The online service, launched in conjunction with the Energy Storage Association’s Virtual Conference (ESACon20), is targeted at systems specifiers and integrators for utility and renewable energy companies and presents them with a series of potential battery partners, before linking them directly with battery manufacturers.

Just like human dating apps, users tap in information about themselves together with details of their expectations and requirements. Using an intelligent algorithm based on battery industry expertise, a range of battery solutions best suited to their needs are identified in real-time.

Dr Alistair Davidson, Director of CBI said: “We’re aiming to bridge the gap between utilities and renewable energy providers and battery manufacturers by demonstrating the wide range of reliable, high-performance advanced lead batteries available.

“Our research Consortium of battery manufacturers has found that their customers needed a simpler way to sort through the range of choices to identify the best battery for their energy storage system.

“Our battery matchmaker will help demonstrate that there are a range of options available, where advanced lead batteries are best-suited to their needs, that allows them to find a tailor-made solution for their specific system.”

“We’re seeing massive growth in demand for battery energy storage across the globe which means we need many more batteries. This new tool helps users consider the range of potential solutions and puts them in touch with potential partners in the shape of the manufacturers.”

With the energy storage market expected to grow at nearly 25% in the next five years, batteries will be one of the key energy storage technologies.

“All battery chemistries will have a part to play achieving future clean energy targets.” added Dr Davidson. “One of the advantages of using advanced lead batteries is that they combine reliability, high technical performance and cost-effectiveness with a recycling rate of almost 100% in North America and Europe.”

The technology is already widely used by utility and renewable energy companies for projects ranging from large-scale peak-shaving and frequency regulation projects to microgrids and off-grid systems.

The battery match service is a collaborative effort between the lead battery industry and CBI, which brings together robust, technical information from some of the leading global players in one place. Companies including Advanced Battery Concepts, C&D Technologies, East Penn Manufacturing, Electric Applications Incorporated, EnerSys, Exide Technologies, Gridtential, NorthStar Battery and Trojan Battery Company are engaged in the project.

With a user-friendly interface available on desktop and mobile, energy storage end-users can log on to the tool, input their system requirements, and the outcome is a direct match with the battery best suited for their project. CBI Battery Match will enable direct communication between the energy storage company and the battery manufacturer, a streamlined process where inputted information results in the output of a battery.

END

Notes to editors:

About the Consortium for Battery Innovation:

The Consortium for Battery Innovation is developing short, informative videos covering all topics related to lead batteries across all the applications they’re used in, from automotive and motive power to energy storage.

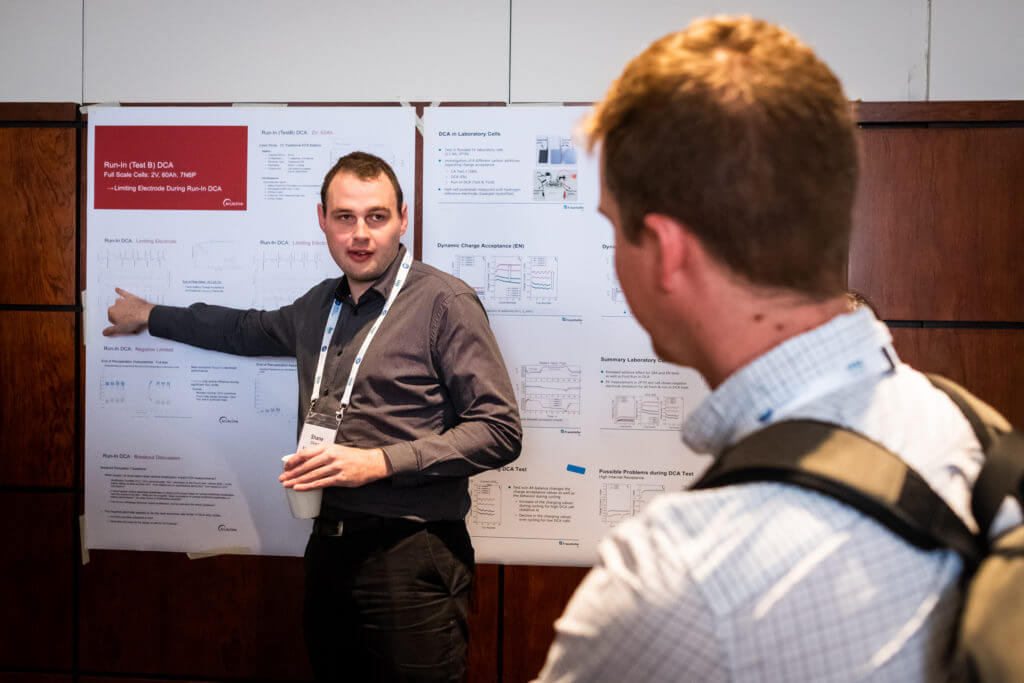

From definitions about the range of lead battery technologies available on the market to explanations covering key terms such as Dynamic Charge Acceptance and cycle life, CBI's Battery 101 Series features our battery experts.

Keep an eye below for the latest videos in the series.

The organisers of the DCA & Heat workshop have been reviewing the situation with respect to the COVID-19 virus (Coronavirus). This situation has developed significantly over the past weeks and, given this, we have taken the decision to postpone the DCA & Heat meeting until 7-8 October 2020. The CBI technical workshop will be postponed until 8-9 October 2020.

The schedule for meetings will remain the same and the location will remain the Royal Scots Club, Edinburgh, UK. We will post an update when registration re-opens for the meetings.

The DCA & Heat Workshop (7-8 October) and CBI Workshop (8-9 October) to be held in Edinburgh, Scotland, UK. The Consortium for Battery Innovation with CENELEC are holding a DCA & Heat Workshop bringing together technical global experts from the advanced lead battery and automotive industries. This follows meetings held Bruges in 2019, Alcalá de Henares in 2018 and Kloster Eberbach in 2017.

The advanced lead 12V battery workshop will be followed on 8 October (starting at 3.30pm) and 9 October (9am-3pm) by a Consortium for Battery Innovation (CBI) European Technical Workshop, to discuss the launch of new projects to be funded under the 2020 CBI technical program.

Agenda - DCA and Heat Workshop

Following the successful events in Bruges, Alcalá and Kloster Eberbach, CBI and CENELEC will be holding a workshop ‘Maximizing hot-climate durability and brake energy recuperation: an automotive workshop on battery technology and standards’ on 7-8 October in Edinburgh, Scotland. View the agenda here.

Agenda - CBI European Technical Workshop

The EFB & Heat workshop will be followed on 8 October (starting at 3.30pm) and 9 October (9am-3pm) by a Consortium for Battery Innovation (CBI) European Technical Workshop, to discuss the launch of new projects to be funded under the 2020 CBI technical program. An agenda will be available in due course.

Registration for both workshops will open in due course.

50% discount is available to students - please contact Anita Wright (Anita.wright@batteryinnovation.org) to obtain the student discount rate.

Hotel

Hotel reservations will open closer to the event.

This will be held on 5-6 November Nashville, Tennessee, USA, starting at 12:30pm with lunch on the 5th November and finishing at 4:00pm on the 6th November. A draft agenda can be found here. Registration for the event can be made here. Further information can be found below.

Prior to the workshop, a bipolar workshop sponsored by Advanced Battery Concepts and East Penn will be held from 9am-12pm. Further information on this workshop can be found below.

The Consortium for Battery Innovation is holding a North American Technical Workshop in Nashville, Tennessee, USA, on 5-6 November 2019. The meeting will begin on Tuesday 5th November from 1.30 pm-5:30pm, and on Wednesday 6th November from 9am-4:00pm. A draft agenda for the workshop can be found here.

A Bipolar Lead Battery Technical Session will be held from 9am-12pm on the 5th November. This session will focus on the history, development, current technology and, most importantly, the future potential bipolar lead batteries at commercial scale. Individual companies will present their current state-of-the-art and planned advances in bipolar battery technology. Audience questions will be addressed in a roundtable discussion with technical experts. A draft agenda can be found here.

Registration is now open. The fee for the CBI North American Technical Workshop is $375 (USD) per person. The fee will cover attendance at the workshop, lunches on 5th and 6th November and a dinner on the evening of 5th November. The workshop is free for students. Students registering need to contact Anita Wright for the discount code before completing their registration. Registration for the event can be made here.

The workshop will be held at the Hotel Indigo Nashville Downtown, 301 Union Street, Nashville, TN 37201 USA. Click here to register online at the hotel for our group. Hotel cancellations must be made directly with the hotel.

A dinner will be held at 7:00pm on 5th November 2019. The cost of this dinner is covered in the registration fee for the Technical Workshop. Registrants are required to confirm attendance for this dinner by selecting yes or no in order to continue your online Technical Workshop registration.

All workshop cancellations must be received in writing by Wednesday 30th October 2019. Registration fees may be refunded, minus a $25.00 processing fee, IF cancellations are made by this date. Please email workshop cancellations to (wright@ila-lead.org) or fax (919-361-1957). After this date, fees will be non-refundable. Substitutions are permitted.

Should you experience any difficulty with the online registration process, please contact Anita Wright at wright@ila-lead.org.

In 2019, car companies met with battery manufacturers in Bruges, Belgium to explore breakthrough technology using advanced lead batteries.

Organised by the Consortium, the EFB & heat workshop was part of a CBI technical workshop.

The innovative event drew battery experts from across the globe to discuss the latest developments in lead battery technology to propel the next generation of advanced lead batteries for automotive applications.

Watch our short video which features global lead battery experts and researchers explore how CBI, in collaboration with the world’s leading research institutes and battery manufacturers, are pushing the boundaries of lead battery technology to ensure their continued dominance in the automotive market.

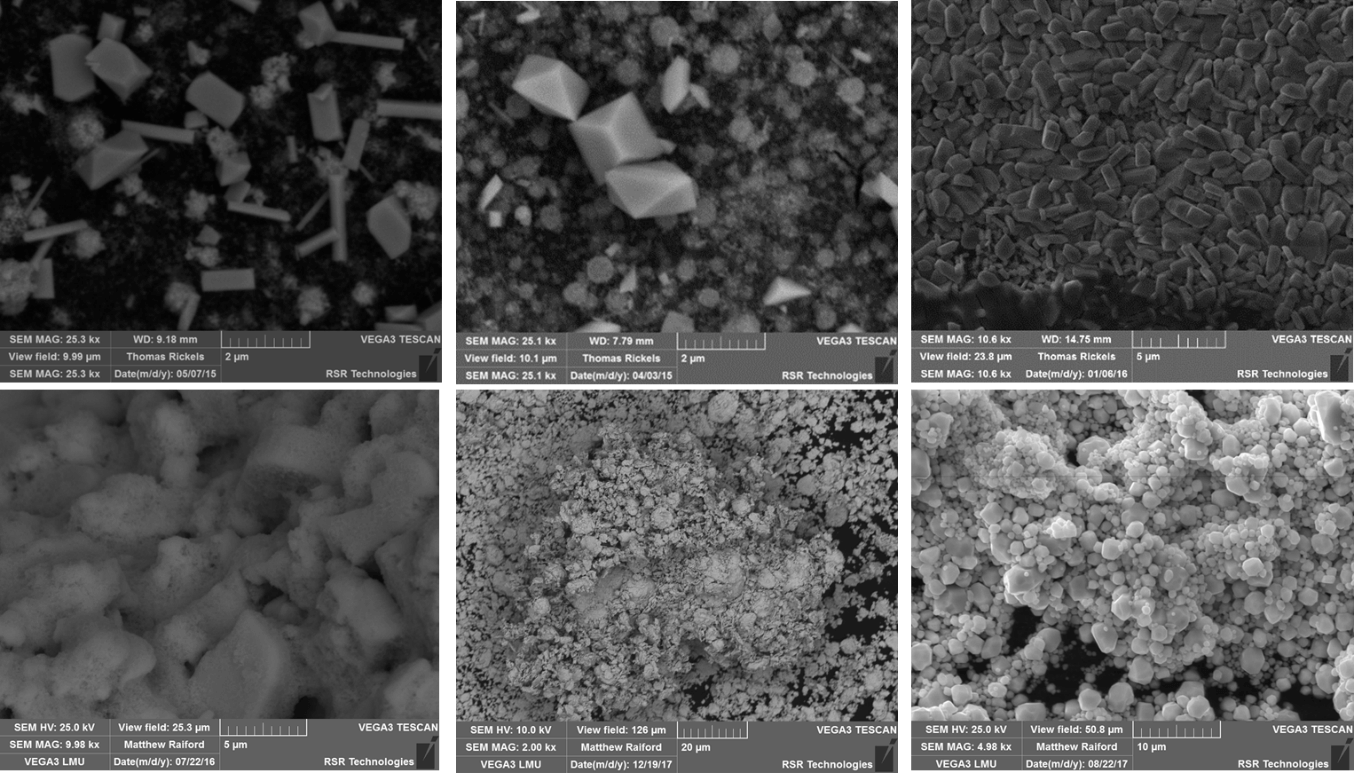

CBI invited member company RSR Technologies, a unit of ECOBAT Technologies, to share their research focus relating to lead batteries and energy storage

By: Travis Hesterberg (RSR Technologies), Tim Ellis (RSR Technologies and Chairman of CBI) and Matt Raiford (formerly RSR, now CBI)

Lead batteries offer a unique cross section of performance, cost, and sustainability. These advantages are accessed because of the very materials that make up lead batteries, mainly lead, plastic and electrolyte. However, performance enhancement in lead batteries must keep pace with the added requirements demanded by an increasingly energy storage dependent world. RSR Technologies’ view of this issue is the best way to change how lead batteries perform is to start from the very beginning: lead.

Alloy developments have been the hallmark of RSR Technologies, and research is centered on producing alloys for the needs of today and tomorrow. Current research efforts use highly resolved materials characterization techniques, such as the Advanced Photon Source at Argonne National Laboratory, to monitor the fundamental growth and dissolution processes that occur in lead batteries and understand how our alloy developments can change these processes for the better.

The role of common elements found in lead alloys on the growth and crystal habit of the many species (PbSO4 and PbO2 for instance) in lead batteries is not understood. Each element has an effect and we are studying how each can benefit or limit the dynamic charge acceptance and cycle life of lead active material. For instance, electron microscopy has shown that the PbSO4 crystal behavior can change drastically based on the elements present in the active material or electrolyte.

The slow dissolution behavior of PbSO4 is of key importance due to its negative effect on charge acceptance and cycle life. The focus on PbSO4 crystal behavior has been fruitful, yielding a new alloy for higher performing lead battery active material, SUPERSOFT-HCYCYLE®. Trace elements in this alloy help govern the crystallization of PbSO4 in the positive and negative electrode. Smaller PbSO4 crystallites with a more easily dissolved crystal habit are formed using SUPERSOFT-HCYCYLE®. The faster dissolution in turn facilitates high charge acceptance and cycle life.

This is just the tip of the iceberg. As we push forward, others are as well. Benefits from SUPERSOFT-HYCYCLE® can be interwoven with the performance enhancements offered by additives, carbon containing and carbon-based electrodes, and bi-polar batteries. All these enhancements working together completely reform the lead battery, advancing the technology to the requirements of the future.

Engineers from European car companies met in Bruges, Belgium, to explore advances in lead battery technology specific for future low emission vehicles.

The workshop, organized by the Consortium for Battery Innovation (CBI) in co-ordination with CENELEC, the European Committee for Electrotechnical Standardization, brought together nearly 100 global technical experts from across the advanced lead battery and automotive industries on 22 and 23 May.

Advanced lead batteries already enable start-stop technology which has helped cut emissions from cars in Europe and the US by up to 10%.

Now, engineers hope to reduce heat and water loss and improve battery performance further as they prepare the next generation of low emission vehicles.

Delegates from around the globe arrived in Bruges to attend the EFB & Heat technical workshop, exploring high-temperature durability tests for advanced lead 12 V batteries.

The benefits of carbon additives have been widely studied and been shown to improve dynamic charge acceptance (DCA) of lead batteries. However, current test standards indicate that the increased use of carbon for micro and mild-hybrids may result in high-temperature durability issues.

Lead batteries are the dominant automotive battery technology, with virtually every vehicle on the road today containing a lead battery. Automotive market dominance has been maintained through recent performance improvements that have been spurred by research and innovation by the lead battery industry, which has included studies into a range of additives such as carbon.

Encouragingly, recent research conducted by CBI members under real-world conditions has indicated that the side effects of carbon additives may be significantly overestimated and may be a result of the ways in which batteries are tested.

Significant new opportunities in micro and mild-hybrid vehicles are available for lead battery technology if these issues can be addressed and overcome through continued research, innovation and collaboration within the industry.

Following successful meetings in Eberbach and Alcalá, the workshop in Bruges facilitated the interaction between OEM engineers and lead battery scientists from around the world to work and plan collaborative projects and experiments focused on exploring high-temperature durability improvements and water loss mechanisms in lead batteries.

A series of plenary talks outlined current and possible methods used to continue improvement in advanced lead battery technology. Water loss mechanisms, new gas monitoring instrument development, research methods for new additives, and new tests developed to study these issues were just some of the topics covered in the intensive 2-day technical workshop.

The lead battery industry, through collaborative CBI technical workshops such as the EFB & Heat workshop, is continuously researching and striving to improve and innovate in lead battery technology to meet the future demands of automotive applications. The workshop in Bruges is the latest partnership between CBI, CENELEC and the European car industry to support lead battery innovation.

The work of CBI and its members does not end in Bruges. Working groups have been established in collaboration with important industry organizations to focus on unique issues that will be developed over the coming year. The lead battery industry will continue to research and innovate to propel automotive lead battery technology into the future.

Two CBI members, Narada and Microporous, have been acknowledged as ‘honorable mentions’ by the judging committee at the U.S. annual Battery Council innovation awards.

Narada has partnered energy storage operator Upside Group in an innovative frequency regulation project, which represents the first large-scale application of lead-carbon batteries in grid-level frequency regulation energy storage systems.

The project was for the German power grid (see the CBI case study here) and the installation, at Langenreichenbach, has a planned construction capacity of 75MW. The installed capacity of the first phase of the project is 16.4MW, and the peak energy storage capacity can reach 25MWh. This project consists of 18 containers, and the battery consists of 10,584 units of 1200Ah lead-carbon valve regulated cells. It is powered by nine inverters, each of which can provide 1.8 MVA.

Narada was one of the pioneers in terms of developing lead-carbon battery systems in energy storage. The company says this project is the first investment and operation model project in the overseas market.

Narada chose Germany as a test location because its utilization of renewable energy is one of the most advanced in the world. Its power grid frequency regulation market is thus a mature power market auxiliary service trading market.

Narada’s project development team was responsible for the finance and development of the entire project. Narada will work with Upside to finish building the project, with a total investment of around €42 million ($47 million).

Meanwhile, the awards committee said that separator product developer Microporous’ innovation — a product known as the DCA Booster Mat — provides greater dynamic charge acceptance without needing any change for the negative active material in the battery.

The Booster Mat can be bundled with the firm’s SLI or industrial separators and is suitable for enhanced flooded batteries — meaning that it allows charge acceptance optimization in high rate partial state of charge requirements (such as in start-stop applications).

Microporous hopes to have completed prototype testing in the next 12 months. It will then develop partnerships with battery companies to evaluate and market the product.

Divya Tiwari, Technical Manager at Microporous, said the innovation offers excellent charge acceptance in industrial markets such as motive power, where opportunity charging is required.

Lead battery-powered energy storage highlighted by research consortium’s online map

A digital map detailing more than 120 lead battery-powered energy storage projects has been unveiled by the Consortium for Battery Innovation (CBI).

The map, published online ahead of the Energy Storage Association’s annual conference held in Phoenix, Arizona, includes diverse case studies demonstrating successful lead battery energy storage installations from the United States, to Asia and Europe.

The feature is included on the Consortium for Battery Innovation’s website.

Through a range of case studies, the map details how lead battery storage is supporting utility and renewable energy systems. This includes providing back-up for local power grids and supplying off-grid electricity to power remote communities.

CBI Director Dr Alistair Davidson said: “We are seeing growing interest in lead battery energy storage for utility and renewables systems all over the world. The aim of this initiative is to highlight some of these installations and encourage companies to share other examples we can highlight demonstrating the variety of projects currently in place.”

“Our analysis suggests demand for battery energy storage will increase significantly in the next five years. This new tool will allow us to demonstrate that the latest lead battery technology is supporting a wide range of installations with reliable, safe, sustainable and cost-effective energy storage.

“A focus of CBI is to conduct pre-competitive research to support development of the next generation of lead batteries which will significantly extend both battery life and performance, to support diverse energy systems and electrification.”

ENDS

Note to editors:

Consortium website:

The Consortium for Battery Innovation with CENELEC are holding a workshop bringing together technical global experts from the advanced lead battery and automotive industries. This follows meetings held Kloster Eberbach in 2017 and Alcalá de Henares in 2018.

The advanced lead 12V battery workshop will be followed on 23 May (3.30pm-6pm) and 24 May (9am-3pm) by a Consortium for Battery Innovation (CBI) European Technical Workshop, to discuss the launch of new projects to be funded under the 2019 CBI technical program.

Agenda - EFB and Heat Workshop

The “EFB and Heat” Workshop will trigger discussion and establish co-operation between battery experts working in all parts of the value-added chain. Download the agenda here.

Agenda - CBI European Technical Workshop

The CBI European Technical Workshop agenda can be downloaded here.

Both the EFB & Heat workshop and CBI Technical Workshop will take place at the Crowne Plaza Hotel in the ancient city centre of Bruges, Belgium.

We have negotiated a hotel rate of Euro 137 per night and you can make your hotel booking using this link. The latest date for making a room reservation is 1 April 2019. We recommend early bookings as Bruges is particularly busy over the conference dates.

Registration for both workshops can be made here.

50% discount is available to students attending the meetings. Please contact Anita Wright to obtain the student discount code.

Further information and a draft agenda for EFB and Heat can be found here. For assistance with workshop registration, please contact Anita Wright. For assistance with hotel details, please contact Maura McDermott.