ORLANDO, FL — April 29, 2025 Battcon, organized by the Consortium for Battery Innovation (CBI), is the industry’s benchmark event for real-world application training and the latest critical developments in stationary battery systems. Today, Battcon announced that the IEEE Power & Energy Society (PES) will be the technical co-sponsor for its 2025 event. This marks the first technical co-sponsorship between Battcon and the IEEE Power & Energy Society, expanding the conference’s global reach and technical impact.

Scheduled for Aug. 3–6, 2025, in Orlando, Florida, Battcon brings together engineers, operators, manufacturers and end users to address critical challenges in backup power systems for many different markets like data centers, energy storage systems, utilities, and telecommunications. With IEEE PES involvement, Battcon 2025 will be included on the IEEE Conference Search/Call for Papers website, and conference materials will be eligible for archival in IEEE Xplore®, expanding access to speaker research and technical findings across the global energy community.

“The involvement of IEEE PES as a technical co-sponsor enhances the already outstanding technical content at Battcon 2025,” said Dr. Matt Raiford, senior technical director of the Consortium for Battery Innovation. “Their role in co-publishing and archiving the conference’s peer-reviewed technical papers ensures that our speakers’ contributions are preserved and shared with a global network of power and energy professionals. This partnership strengthens the value of Battcon as a platform for advancing real-world battery applications in critical infrastructure.”

The IEEE Power & Energy Society, the world’s leading forum for electric power and energy innovation, has more than 42,000 members worldwide. Their participation furthers Battcon’s mission to deliver top-tier technical education and drive advancements across grid storage, telecom backup and data center UPS systems.

Battcon, organized by the Consortium for Battery Innovation (CBI), is where technical expertise meets real-world application. The 2025 event will feature expert-led sessions, pre- and post-conference workshops, an expanded expo, and targeted networking receptions connecting professionals across the stationary battery community. In Battcon’s uniquely independent exhibit hall, attendees can engage directly with leading manufacturers, suppliers and service providers. Learn more at www.battcon.com.

The European Energy Transition

By Nicola Filizola

As the world copes with the urgent need to address climate change and reduce greenhouse gas emissions, Europe has been leading the charge in transitioning to a cleaner and more sustainable energy future. The European energy transition is a comprehensive shift from traditional fossil fuels to renewable energy sources, such as wind, solar, hydro, and geothermal power. Among the critical components enabling this transformation, lead batteries have emerged as a key technology that plays a pivotal role in the transition's success. In this article, we will explore the energy transition in Europe and delve into the essential role that batteries are playing in shaping the continent's greener and brighter future.

The Growth of Renewable Energy in Europe

The European Union (EU) has been at the forefront of advocating for clean energy and sustainability. Through initiatives like the European Green Deal and the Paris Agreement, EU member states are committed to reducing their carbon emissions, fostering innovation in clean technologies, and achieving climate neutrality by 2050.

One of the main challenges of integrating renewable energy sources into the existing energy infrastructure is their intermittency. Solar and wind power, for instance, depend on weather conditions and daylight availability. To ensure a stable and reliable energy supply, an efficient energy storage system is essential, and that's where batteries come into the picture.

The Challenge of Intermittency

Unlike conventional power plants that can provide a consistent energy output, solar and wind power are dependent on weather conditions and natural variations. Cloudy days and calm winds can lead to a drop in power generation, causing fluctuations in the grid. This intermittency poses challenges to grid stability, and the power supply must be balanced in real-time to meet demand. If renewable energy sources are to dominate the energy mix, an effective and efficient energy storage solution is imperative to address this variability.

Batteries: The Key to Storing Renewable Energy

Batteries are essential components of the energy transition as they serve as a bridge between renewable energy generation and consumption. These energy storage systems can store surplus electricity when generation exceeds demand and release it when demand surpasses generation. In essence, batteries help to smooth out the intermittent nature of renewables and provide a stable supply of electricity to the grid.

Batteries act as buffers, absorbing excess energy during periods of high generation and releasing it when generation dips. By doing so, they stabilize the grid and ensure a steady supply of electricity, reducing the risk of blackouts and power disturbances. Moreover, batteries can respond rapidly to fluctuations in demand, providing grid operators with a valuable tool to manage the grid effectively.

The energy transition in Europe is also characterized by a shift towards decentralization, with an increasing number of small-scale renewable energy installations, such as rooftop solar panels and community wind farms. Batteries play a vital role in this decentralized energy landscape by enabling consumers to store and manage their locally generated energy. This promotes energy autonomy, reducing the reliance on centralized power plants and enhancing energy security.

Batteries make it possible to integrate a higher share of renewables into the grid. By storing excess energy during periods of high generation, batteries ensure that the energy is not wasted and can be used during times of low generation. This feature is particularly crucial during seasonal variations when renewable output may vary significantly.

Batteries also play a significant role in electrifying transportation, another essential aspect of the energy transition. The growth of electric vehicles (EVs) is dependent on advanced battery technology, allowing for longer driving ranges and faster charging times. Widespread EV adoption not only reduces greenhouse gas emissions from the transportation sector but also opens up the possibility of using EV batteries for grid storage through vehicle-to-grid (V2G) technology.

In conclusion

The energy transition in Europe represents a monumental effort to combat climate change and create a sustainable energy future. The integration of renewable energy sources is a crucial step in this journey, but their intermittent nature presents challenges that must be addressed. Lead batteries, together with other technologies, emerge as the silent protagonists, providing a robust and reliable energy storage solution. From enhancing grid stability and enabling renewable integration to empowering decentralized energy systems and fostering electric vehicle adoption, lead batteries will play a multifaceted role in reshaping Europe's energy landscape. As technology advances and costs continue to decline, the potential of batteries will only grow, propelling Europe towards a cleaner, greener, and more resilient energy future.

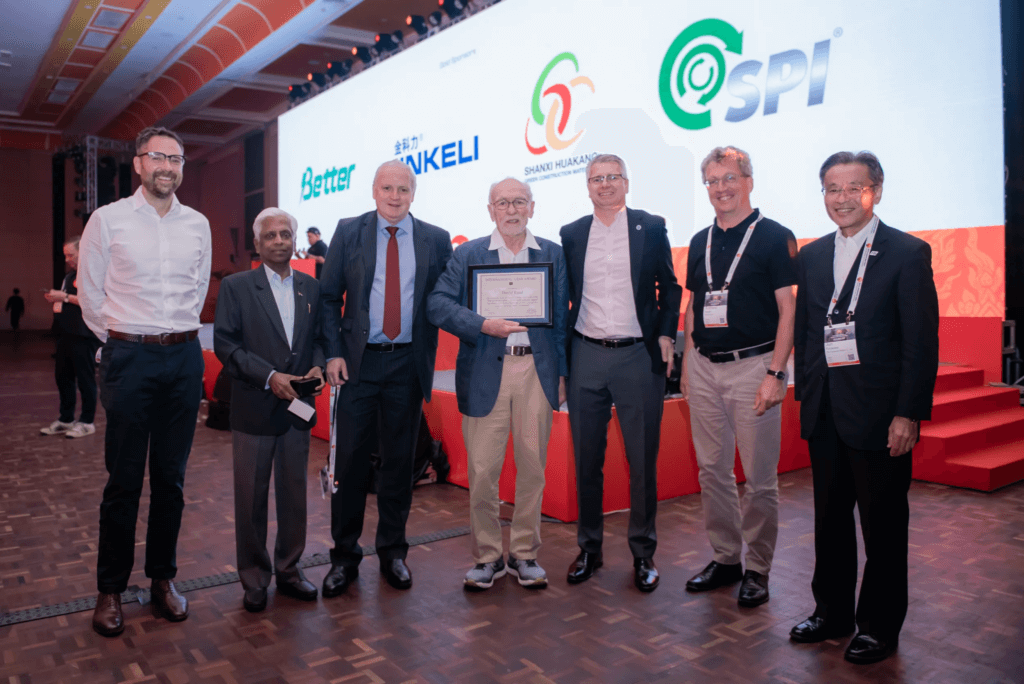

The Consortium for Battery Innovation connected with over 730 attendees from 42 different countries representing 319 different organizations in Siem Reap, Cambodia for the 20th Asian Battery Conference (20ABC) and the Recycle 100 International Secondary Lead Conference and Exhibition that featured global discussions on the world of lead, recycling, lead-acid batteries and energy storage.

CBI Senior Technical Manager, Dr. Matt Raiford said that lead batteries are made and produced in over 100 countries, and the Asian Battery Conference was a great venue to see how Asia, Africa, and other areas of the world are innovating and improving lead battery technology. For instance, CBI member companies, Hammond and Borregard, demonstrated deeper understandings of additive chemistry as a low threshold method to improve lead batteries for many different applications.

CBI participated in the line-up of over 45+ conference speakers during 20ABC to share our technical battery knowledge and insights with attendees with presentations that included:

The 20th Asian Battery Conference provided a chance to join several technical sessions providing valuable insights from industry leaders, market analysts and technical experts about the lead battery industry. Several speakers including CBI member companies presented innovations and advancements, such as new active material formulations and improvements in the manufacturing process, for several applications of lead batteries.

Dr. Begüm Bozkaya, CBI’s Technical Manager, shared that there are definitely future opportunities for lead battery technology in Asia and other continents of the world via the implementation of new developments to deliver cost-efficient, safe, and sustainable battery solutions.

8th International Secondary Lead & Battery Recycling Conference covered several aspects of lead recycling industry in Asia and Africa. Bozkaya shared that many of the speakers addressed the current issues related to environmental challenges, financial, and social risks in the secondary lead industry. It was beneficial for attendees as some of the ILA & CBI members also illustrated their new techniques and developments in recycling of lead batteries.

Recycle 100 illustrated the ins and outs of running battery recycling centers - the heart of lead battery sustainability. Raiford was intrigued by ongoing improvements at Asian recycling operations, especially in increasing recycling efficiency - and how these improvements were presented to representatives from dozens of countries.

The city of Siem Reap, Cambodia was an amazing host and we enjoyed seeing all the beautiful areas in that region. The 20ABC was a successful event from all angles – including the achievement from the event’s charity initiative. The "ONE Minute Giveback", exceeded organizer’s and sponsor Sorfin Yoshimura’s expectations, by raising over $22,000.00 USD to help fund a bed in the Oncology Department of Angkor Hospital for Children.

We look forward to next year’s events and continuing the technical conversations around lead batteries.

Our members are vital for CBI’s ecosystem as they help us develop messages, interventions, roadmap, and our own call for projects. This helps CBI conduct pre-competitive research that benefits all CBI members, the battery industry in general and the wider research community.

As a large battery maker, Clarios are an invaluable member. Additionally, Clarios were instrumental in setting up and supporting the work of CBI’s Research and Innovation Manager, Dr Carl Telford, in developing public funding opportunities in Europe and deliver exciting, game-changing projects.

CBI team visited Clarios HQ in Hanover, Germany, to strengthen this collaboration and to learn more about their current R&D work.

« We have developed the Start-Stop technology in AGM to become the benchmark technology for premium cars with micro-hybrid functionalit. Innovation in process technology like the Clarios Power frame technology has been leading the way and is presently the standard in the industry. For the future, we see a lot of life left in Lead technology. We see further innovation potential in charge acceptance and cycle life to further improve the technology » (Dr Christian Rosenkranz - Vice President Industry and Governmental Relations EMEA at Clarios & Chairman at CBI)

Watch the first video from CBI's visit to Clarios:

NEWS RELEASE

The U.S. Army has chosen advanced lead battery energy storage systems to enhance its operational effectiveness in disaster zones and in combat.

A project led by Paragon Solutions, Inc., and the Consortium for Battery Innovation (CBI) is providing a new set of systems that can provide power for critical military operations anywhere in the world.

Paragon, a woman-owned engineering firm, and a member of the Consortium for Energy, Environment, and Demilitarization (CEED), partnered with CBI, a global lead battery research hub, to develop the winning proposal in response to a request issued to CEED members by the Consortium Management Group (CMG). The effort is sponsored by the U.S. Government under an Other Transaction Agreement between CMG and the U.S. Army Corps of Engineers.*

Paragon and CBI will develop transportable, robust, lead battery energy storage systems that can be integrated into tactical microgrids and demonstrated at the Contingency Basing Integration Training Evaluation Center (CBITEC) at Fort Leonard Wood, Missouri. The CBITEC site is managed by the U.S Army Engineer Research and Development Center, Construction Engineering Research Laboratory (ERDC-CERL).

The eighteen-month $3.5 million program also seeks to demonstrate how U.S. Army units can use lead batteries sourced from the Department of Defense supply system and from locally available sources such as vehicles, while increasing the lifecycle for certain battery types to meet battlefield energy demands.

Retired U.S. Army Captain and government technical lead for this project, Tom Decker, said: “This is an important project to the Army because in any type of contingency environment, while in combat situations or following a natural disaster, it all falls back on the Army Corps of Engineers to provide power to continue operations. And this is where lead batteries come in.”

“By being able to use lead batteries that are available on the ground and make an energy resource out of them, we have the ability to continue whatever mission we’re on, be it disaster relief or engaging in combat.”

“This just adds to our capabilities. The durability of lead batteries has been proven over many decades so we know what we’re getting when we use the technology. But then we get the added value of the advanced lead battery systems which the industry supplies, and this is the technology that makes the systems viable.”

“Lead batteries give us the ability to deploy energy storage systems anywhere in the world, enhancing our resiliency. And one of the current US administration’s priorities is reducing carbon footprint, so by decreasing our use of fuel and adopting more innovative energy storage systems, we’re reducing our carbon footprint too.”

Implementation of the systems will be done to NATO specifications, and if successful, would allow for deployment in many different countries. This solution aims to overcome issues with host nation power grids by designing an energy storage system that accepts host nation power, stores it, and then provides it in a form that is compatible with U.S. Army equipment.

The resiliency, safety and reliability of power supplies are priorities for military operations. Lead batteries have been chosen for the project as the technology of choice because of their inherent safety and robustness in extreme weather as well as their availability in the field. Using lead batteries would provide Army Commanders with local sources of batteries in vehicles and telecommunications towers around the world.

The Paragon/CBI team will develop energy storage systems providing between 125kWh to 250kWh of critical energy using three different lead battery technologies provided by US-based battery manufacturers, Advanced Battery Concepts (ABC), East Penn Manufacturing and EnerSys. These operational workhorses will be transportable, easy to operate by military personnel, and can be integrated into tactical microgrids to provide power for critical loads.

The project team will also develop a ‘plug-and-play’ 30 kWh energy storage system, which will give soldiers the ability to plug into an energy storage source made up of used lead batteries found in locally available sources, such as vehicles. Marcus Ferguson, ERDC-CERL project officer, and manager of the CBITEC site said: “After Hurricane Maria in Puerto Rico in 2017, approximately 130,000 damaged vehicles were lying unused with an untapped energy source: lead batteries. If this energy could be harvested, future disaster relief and other military operations, wherever they are in the world, could be provided with reliable, low-cost energy”.

The prototype lead battery energy storage systems will be constructed and tested in various simulated duty cycles to recreate typical field conditions for military operations. The aim is to develop systems that could be rolled out across the U.S. Army. Furthermore, when the lead battery ESS prototypes are connected to Army tactical quiet generators (TQGs) the systems will provide low heat signature and quiet energy assets - essential requirements for U.S. Army activities in the field.

Dr. Matt Raiford, CBI project manager, added: “Lead batteries have been chosen for this important project based on their resilience, consistent performance at all temperatures and their accessibility. This will set a benchmark for smaller microgrids providing essential power and security in a range of settings from remote rural areas to larger military installations.”

Raiford continued: “CBI is committed to developing advanced lead batteries for energy storage applications and the recognition that this mainstay technology has been chosen to support U.S. Army operations is testament to the inherent safety, reliability and sustainability of the technology.”

*Effort sponsored by the U.S. Government under Other Transaction number W9132T209D001 between the Consortium Management Group, Inc., and the Government. The U.S. Government is authorized to reproduce and distribute reprints for Governmental purposes notwithstanding any copyright notation thereon.

The views and conclusions contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of the U.S. Government.

END

Notes to editors:

1: For more information please contact Hywel Jarman in the CBI media office on +44 7718 483887. Visit www.batteryinnovation.org.

They are the future of the lead battery industry: highly-educated, motivated and brimming with new ideas and ambition. CBI spoke to three talented scientists, new to the lead battery industry, to find out more about their perceptions of the workplace and to hear their suggestions about how the industry can continue to attract the brightest and the best.

Max Parker, a PhD Student at Warwick University (United Kingdom); Miguel Rodríguez Gómez, PhD Student at INMA (Spain) and Grace Rocha, a Scientist at ITEMM (Brazil). From industry’s first impressions, learning new areas for innovation and crucial for our future, to the industry’s urgent effort to attract more young talents, they are the voices of a new generation inside the lead battery industry and here’s how they feel about it.

CBI : Tell us a bit about when you first joined this industry. What were your expectations ?

Max : « Batteries are an exciting area with a lot of areas to look at and lots of different things to analyse. Before joining the industry I didn’t really know what made one battery better than the next, why this one can charge faster than the other or why this one lasts longer than the other. Lead batteries are interesting because they have been around for such a long time, but there is still so much more to look at, and still so much more to learn. »

Grace : « To be really honest I didn’t think very much about the whole Lead Battery industry. I just wanted to be part of a great industry with a great social impact, which everybody near around knows Moura does to the city and to the state. Now, I am truly surprised with how much I enjoy working on the field. I see that there is a excitingopportunity for progress learning and development in every area of lead battery technology. »

Miguel : « I had just finished my masters degree and I was looking for research into something related to the energy or climate crisis. Energy storage is essential to be able to cover the off-peak hours of renewable production, and to move away from fossil fuels (which also have rapidly diminishing reserves). So, I started to look for research lines related to batteries. The truth is that I knew almost nothing about lead batteries, I thought there were only in cars and little else, but when I learned a little more and discovered that they can be used for many things and above all that recycling is very high, I decided to go for it.”

CBI : And now that you’ve been working for the industry, what’s your current perception ?

Max : « I think that there are lots of challenges ahead for the world of lead batteries. I would like to see more innovation to meeting these challenges, especially in the energy storage sector, which will be a big part of the future of lead batteries. Innovation is constant, and constantly necessary, because the use cases of lead batteries are changing. We need to be providing the new and innovative batteries of not just today but also the future. »

Miguel : « There is still much to discover and improve, and I think that since the materials of the batteries are cheap and abundant (but also safe and resistant), it will be very important in the years to come. On the other hand I think that production is too focused on the automotive industry. There is less and less demand for cars worldwide and energy is becoming more and more expensive, so I am convinced that the future is energy storage and back up systems. »

CBI : What can you learn from working with professionals who have been in the industry for a long time? What do you learn from each other in your projects ?

Max : « Professionals with a lot of experience have a wealth of knowledge and, but it is up to them to pass that on. I started from zero knowledge and having an experienced professional to provide guidance would have been of great help to ensure that I wasn’t misunderstanding things. Since being involved with the CBI, it has enabled contact with battery experts within companies and other universities. Some of them can share knowledge that is not as well known or written about in technical literature. And this leads to better experiments, better understanding and better development. »

Grace : « One of my favorite things about my job is the opportunity to network with everybody in the global lead battery chain. I’ve noticed that there is so much contribution on the field. For example, every time I have a call with a supplier, a partner, a specialist, I learn something new. And I feel they are always willing to help, they are so welcoming to answer my questions (and I do have lots of questions !). The Lead battery is not a technology that you learn through on college here in Brazil. So everything I know so far, I’ve learned from their experience. I’m really glad to see how some of the ideas I’ve given actually worked and contributed with the development of the projects. »

CBI : What things would you like to happen in the industry to attract more talent ?

Miguel : « There are two main things to attract younger professionals. The first is to raise awareness of the lead battery industry, communicating its importance globally and showing that it is possible to have a fruitful career in it. The second is to communicate that it is a technology that can help with very important problems that especially (but not only) the younger generations are going to suffer, such as the climate crisis, the energy crisis and the resource crisis. For me personally, it is essential that 99% of the lead in batteries is recycled. I would not like to work with a polluting technology that ends up accumulating in landfills. I also believe that research lines focused on renewable energy storage and batteries for trains (which is the most efficient and less polluting transport, both for people and goods), should be encouraged. »

Max : « From my perspective in the world of academia, I would like to see more PhD funding, more internships, sponsorships and more university partnerships. Early career development and career paths can encourage people to join. Another option would be a summer job/internship/work experience in a battery company. Getting young people into the world of batteries requires investment in them, and guidance. With the right support and guidance a PhD student can produce some excellent research. But without the right funding they will go to do something else, or a PhD in another field. »

Grace : « I believe the answer is undergraduate students. Talking about the Brazil scenario, I would like to see the industry work more with universities. For example, investing in programs to develop new projects for undergraduate students. I think that would be a win/win situation : The students would have the opportunity to work on a real life problem and learn about the lead battery from experts ; and the company would have the opportunity to work with new researchers and a new university department. This is a great way for students to be more prepared before they join a lead battery company.

I think even quick programs like a “Battery Marathon”, something like a Hackathon, would make students curios about the area and starttheir development from college. Today, at ITEMM we are already making this approach. Recently we started the implementation of a research and innovation center in a technical college in the city, focused on developing young talent.»

CBI : Would you recommend the lead battery industry as a place to work for young scientists?

Miguel : « I recommend the lead battery industry to anyone interested in energy storage. It is a well-known technology but there is still a lot of room for improvement, and research is always interesting and fun. From my work I especially like the direct relationship with the industry, which is eager to generate more and more research projects. This year at ELBC, I have learned a lot and it has been a very rewarding experience to learn about the latest advances in research and also to see what the market trends are. »

Grace : « I do recommend. The more I work on the field the more I see there is still so much room for new ideas. It is a great time to be working in the battery field! Environmental care is one of the major concerns around the world, and batteries are key to this! One of the great things about the lead battery industry is that we are a safe technology, critical for energy storage, which helps reduce the global carbon footprint. Something people forget is that we are also an industry that has a true circular economy. »

Both Max and Miguel won this year’s CBI & EUROBAT Student Award, a great way to promote their work in the industry by bringing them to ELBC 2022 as speakers. In 2022, CBI also visited ITEMM in Brazil, where we had the chance to meet Grace and learn about her work at the Research and Development Department.

Interested about their work with CBI? Check out our blogs and videos:

CBI is co-organising an event with the India Lead Zinc Development Association (ILZDA), International Lead Association (ILA), International Lead Zinc Study Group (ILZSG), Indian Battery Manufacturers Association (IBMA) and the Recycling and Environment Industry Association of India (REIAI) to discuss the role of the lead industry in Energy Storage, E-mobility and Environment.

The International Conference on Lead & Lead Batteries will take place in New Delhi, India from 5-6 December 2022 and CBI’s Director, Dr Alistair Davidson, will talk about innovation for lead batteries and CBI's exciting new projects coming up involving energy storage systems.

This world class event is a great opportunity for stakeholders of the lead and lead battery industry to learn more about the latest technology developments and trends.

The next North American CBI Technical Workshop will be held at the Durham Convention Center, Durham, North Carolina from 14-16 November 2022. The workshop will start at 2pm on the 14th November and finish at 1pm on the 16thNovember.

This workshop will cover:

Workshop only for CBI members. For more info about the event and CBI membership, please contact Anita Wright at anita.wright@batteryinnovation.org

There are clear goals from the EU to decarbonize and decrease the reliance on fossil fuels. Understanding the fundamental contributors to lead battery failure at a molecular level will enable stronger cycling performance of lead batteries in all applications, such as microhybrid and energy storage applications. Batteries in these applications serve as the main tool to decarbonize the European utility grid and automotive fleet, the most important areas underpinning the EU Green Deal.

The main objective of this project is to analyze the different electrochemical processes and reactions that take place inside the battery electrodes during operation. To this end, CBI, INMA, and Exide Group are using, for the first time, in-operando neutron scattering techniques by placing real operating cells, built using the same components as in the factories, in a neutron instrument and collecting diffraction patterns and images from inside the cell, with both spatial and time resolutions, during the charge and discharge processes.

Also using neutrons because its penetration capacity in matter is much higher than that of other particles, as X-rays or electrons, used until now for battery analyses. In this way, it's possible to study real thick cells, about one centimeter in thickness, in real operating conditions.

This is an approach never used before in lead cells.

Learn more about this project through our project update video:

On October 4, CBI brought together a digital panel to discuss the critical role of batteries for Europe’s sustainable transition. As part of Europe's Sustainable Energy Week, supported by the EU Commission, the virtual event provided an open discussion around the importance of a level playing field amongst technologies in Europe and featured European case studies where advanced lead batteries are providing reliable, recyclable and safe energy storage.

CBI’s Research and Innovation Manager, Dr Carl Telford, opened the event by showcasing our recently launched Technical Roadmap, to illustrate that “sustainable economies need batteries”. If policy makers want to solve the problems of climate change and pollution, while moving from a linear to a circular economy, then industries will “need a proper deployment of battery technologies and energy storage”, and this is where Europe’s lead battery industry plays a key role.

From Exide Europe, Holger Fricke, Director Basic Research R&D EMEA, presented the benefits of Exide’s “on-site solar installation in Portugal”, that combines lead battery energy storage with renewable energy. Carbon emissions were reduced by more than 20% and energy management was improved, turning this case study into a real-world example of decarbonisation, with the installation facilities now being used as a showcase.

Peter Stevenson, Senior Technical Co-ordinator at GS Yuasa, joined the event to discuss the importance of hybrid solutions for Europe’s sustainable energy future. Using an example of the “world’s first container of dual chemistry energy storage system”, he highlighted the “complementarity and flexibility” between lead and lithium battery technologies.

While moderating the panel, Patrick Clerens, Secretary-General at EASE, reflected on the need of a level playing field between different technologies and stated that “no one can pick a technology winner”. Europe needs more batteries and new battery technologies, including hybrid ones, and through this it is possible to have “the best of both worlds”.

There are already some EU industrial and research initiatives going on to demonstrate how batteries can work together to reach the energy demands, such as the European Battery Alliance, Batteries Europe, Batteries 2030+ or IPCEI's. However, it remains important to share the message that a wide array of energy storage and battery technologies are needed to address the flexibility requirements and support the energy transition and the EU green goals, including lead batteries.

By the end of the discussion, it was clear that other industries can learn from the lead battery experience since it’s a well-established industry that represents a major example of circularity in Europe. Through research and innovation, enhancing the performance of lead-based technologies will be essential for Europe’s sustainable energy future and create further opportunities for synergies with other chemistries.

Watch the video of the event:

Download the presentations from the event below: