CBI invited member company RSR Technologies, a unit of ECOBAT Technologies, to share their research focus relating to lead batteries and energy storage

By: Travis Hesterberg (RSR Technologies), Tim Ellis (RSR Technologies and Chairman of CBI) and Matt Raiford (formerly RSR, now CBI)

Lead batteries offer a unique cross section of performance, cost, and sustainability. These advantages are accessed because of the very materials that make up lead batteries, mainly lead, plastic and electrolyte. However, performance enhancement in lead batteries must keep pace with the added requirements demanded by an increasingly energy storage dependent world. RSR Technologies’ view of this issue is the best way to change how lead batteries perform is to start from the very beginning: lead.

Alloy developments have been the hallmark of RSR Technologies, and research is centered on producing alloys for the needs of today and tomorrow. Current research efforts use highly resolved materials characterization techniques, such as the Advanced Photon Source at Argonne National Laboratory, to monitor the fundamental growth and dissolution processes that occur in lead batteries and understand how our alloy developments can change these processes for the better.

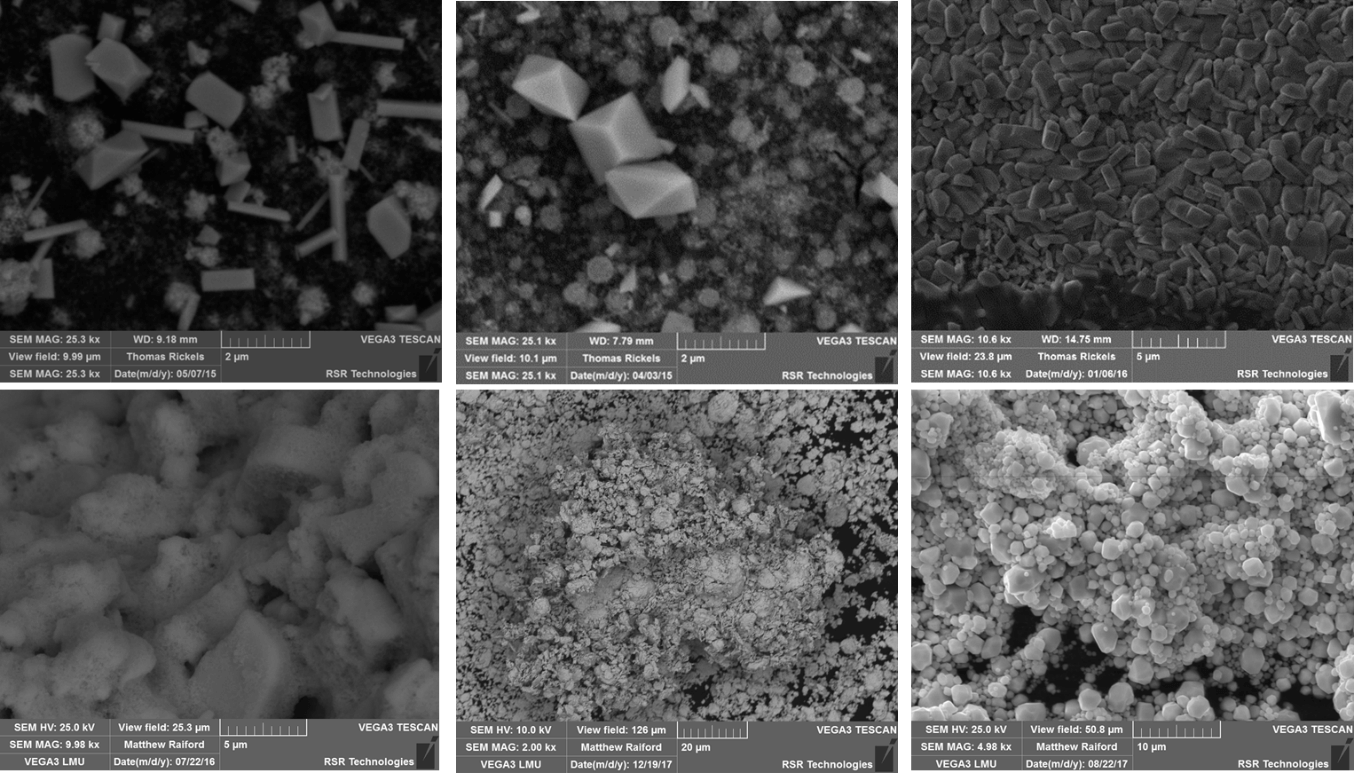

The role of common elements found in lead alloys on the growth and crystal habit of the many species (PbSO4 and PbO2 for instance) in lead batteries is not understood. Each element has an effect and we are studying how each can benefit or limit the dynamic charge acceptance and cycle life of lead active material. For instance, electron microscopy has shown that the PbSO4 crystal behavior can change drastically based on the elements present in the active material or electrolyte.

The slow dissolution behavior of PbSO4 is of key importance due to its negative effect on charge acceptance and cycle life. The focus on PbSO4 crystal behavior has been fruitful, yielding a new alloy for higher performing lead battery active material, SUPERSOFT-HCYCYLE®. Trace elements in this alloy help govern the crystallization of PbSO4 in the positive and negative electrode. Smaller PbSO4 crystallites with a more easily dissolved crystal habit are formed using SUPERSOFT-HCYCYLE®. The faster dissolution in turn facilitates high charge acceptance and cycle life.

This is just the tip of the iceberg. As we push forward, others are as well. Benefits from SUPERSOFT-HYCYCLE® can be interwoven with the performance enhancements offered by additives, carbon containing and carbon-based electrodes, and bi-polar batteries. All these enhancements working together completely reform the lead battery, advancing the technology to the requirements of the future.

25/04/2024