In this edition of CBI’s technical project interview series, Paul Everill, Ph.D., Chief Technology Officer at Black Diamond Structures, shares insights into ongoing work investigating how electrode structure influences performance, degradation and lifetime in lead batteries. The project aims to identify material and electrochemical metrics that support longer cycle life, improved durability and competitiveness for lead-battery technology.

Could you briefly introduce Black Diamond Structures and your organisation’s role in this project?

Black Diamond Structures, LLC (BDS) entered the industry in 2014 and has grown to become a global component supplier to dozens of battery manufacturers. Our company offers MOLECULAR REBAR (MR) carbon nanotube-based solutions for a variety of applications, and contributes to various international research initiatives, including CBI research projects. We have sales teams in North America and Asia, with partners in South America, China, and Korea, helping us to expand our global reach. Our products offer battery makers benefits such as reduced warranty claims, advanced product designs, higher-rate performance, and lower production costs.

I currently serve as Chief Technology Officer. I am tasked with ensuring our internal research and development programs meet customer needs, shepherding our Intellectual Property, managing supplier and partner relationships, and providing technical direction to our sales teams.

What motivated your team to participate in this research, and how does it connect with your wider work in battery innovation?

BDS has been a part of the lead battery industry for over a decade. As a supplier of nanomaterials focused on energy applications, we have access to a suite of unique materials analysis and electrical testing tools. We felt compelled to support the CBI's initiatives and membership by directing a portion of our capabilities to address the critical needs identified in the CBI's Technical Roadmap. We wanted to support the industry with leading-edge research to provide new tools useful in the development of next-generation energy storage batteries.

BDS develops products based on a strong understanding of structure-function relationships. We know how our materials trigger changes in active materials, and how these changes, in turn, modify performance.

Materials research is in our DNA, and extending these principles beyond our own products is a step which helps us deepen our own application knowledge. Using our tools, we aim to quantify how positive active material (PAM) degrades over time, providing new design targets for CBI members to advance energy storage batteries. By identifying specific structural elements that correlate with electrical degradation, we could help support longer battery life or lower total cost of ownership through adjustments using additives, such as MR, or alloys.

This project examines the link between the structure and performance of lead battery electrodes. Why is understanding this relationship important for improving battery design?

Lead battery electrodes are complex, dynamic structures whose crystals shape their performance and resilience. Over a century of research and development has proven that creating and maintaining the correct structure for an application's needs is essential for achieving the desired warranty and performance.

If our work can identify even one material metric that changes predictably over time, that metric could be used to make faster, more informed predictions about cycle life in tests that typically take years to complete. It could help recommend an additive or component that is usually used to address a different issue.

How do collaborations between industry and research partners, such as this one, support progress in lead battery innovation?

Industry and academia move at different paces. Industry tends to move too quickly towards commercial goals, while academia may progress more slowly in pursuit of specialised knowledge. The truth is, the two benefit strongly from each other. Industry helps apply academic knowledge, and academia assists industry in mitigating risks and gaining a deeper understanding of its own data.

BDS positions itself between these two. We believe that technology that is efficiently-paced, science-backed, and relevant to applications is the best way to support our customers and the industry. Often, the industry is unwilling to initiate deeper scientific projects when the immediate value is unclear, but with the support of the CBI, institutions like BDS can step up to leverage their testing capabilities to address that gap.

What impact do you believe these findings could have on the broader competitiveness and sustainability of lead batteries?

The energy market has never been more competitive. If our work can lead to more efficient charging, cheaper or longer-lasting batteries, it will help delay market losses for lead batteries. Or, more optimistically, help lead to retain or increase its market share.

On a personal note, what do you find most interesting or rewarding about working on this project?

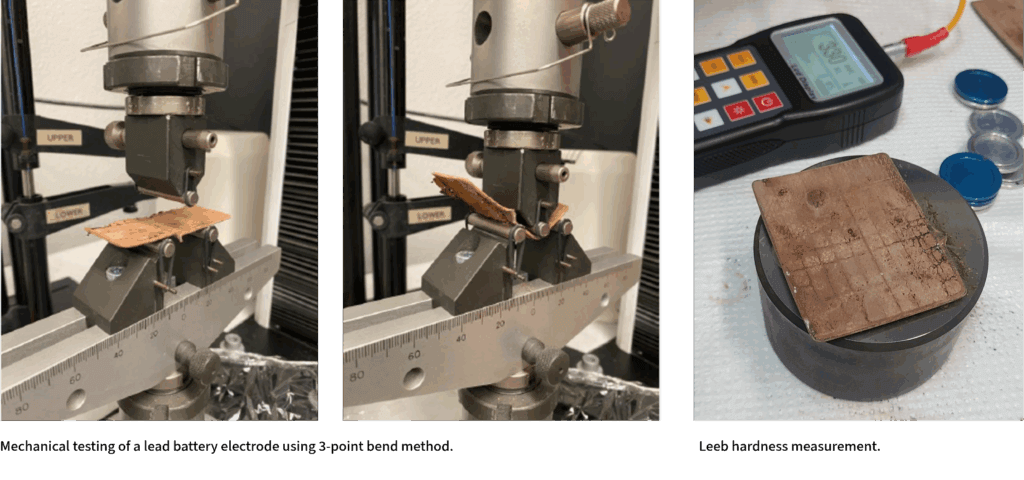

Sharing our work with others has been extremely rewarding. Over the past year, BDS has shared insights using our newly developed mechanical quantification techniques and our in situ PAM characterisation tool, which Dr. Nanjan Sugumaran applied to lead battery chemistries for the first time. The industry has responded with great interest.

Those conversations, suggestions, and engagement have been wonderful, confirming what I always knew to be true: the lead battery industry is uniquely composed of committed and collaborative individuals who often put their industry first and their company second.

Read more about the project here.