As part of CBI’s new interview series highlighting our technical research projects, we spoke with Thomas Wojcinski, Senior Chemist in Research & Development at Hammond Group, to discuss their work on charge recovery and pulse-power behaviour in auxiliary EV batteries. This project examines the material and electrochemical factors that influence these characteristics to support improvements in cycle life, reliability, and the overall competitiveness of lead batteries.

Could you begin by introducing Hammond Group and your role in this project?

Hammond Group is a global supplier of specialty chemicals, including performance additives and raw materials for lead battery systems. The company has over 90 years of industry leadership in providing lead oxides, specialty litharge, polymer-bound dispersion coatings, negative electrode additives, and positive electrode modifiers. We are proud to collaborate and support research initiatives with our customers and respected industry groups such as CBI.

For this CBI project, I am the principal investigator. I lead research, planning, and oversight of the project to meet ethical and regulatory standards. However, this project is a collaborative effort with input and advice from many members of the battery research community.

This research looks at charge recovery and pulse power in auxiliary batteries for electric vehicles. Why are these areas important to focus on?

With current trends, the focus is on improving cycle life under partial state-of-charge conditions. Batteries are expected to charge faster and operate in partially charged states while maintaining a long service life.

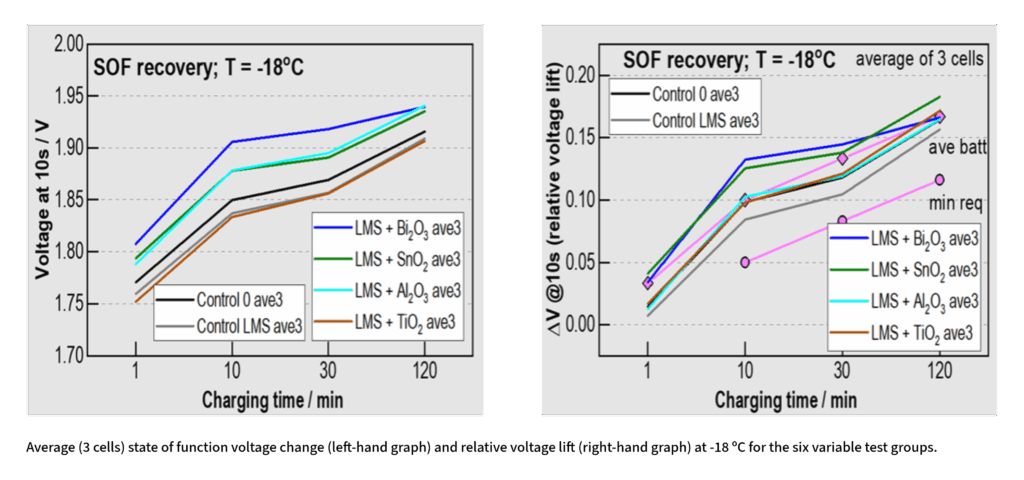

Lead technology needs to improve to remain competitive in the battery electric vehicle (BEV) market. One way to do this is to improve charge acceptance and efficiency. Likewise, pulse power is also a key feature for BEV functional safety. Temperature and the battery's state-of-charge also influence its ability to deliver pulse-discharge power. It's essential to explore these relationships in more depth to optimise products for OEM customers and explore innovative additive improvements.

Many people might not realise how much detail goes into developing new materials for batteries. Could you describe what happens in the lab when you’re testing these additives?

Our development process for additive materials consists of a series of evaluations and stage gates. It starts with identifying potential additive materials from various sources, including our own ideas, academic research, and supplier assessments.

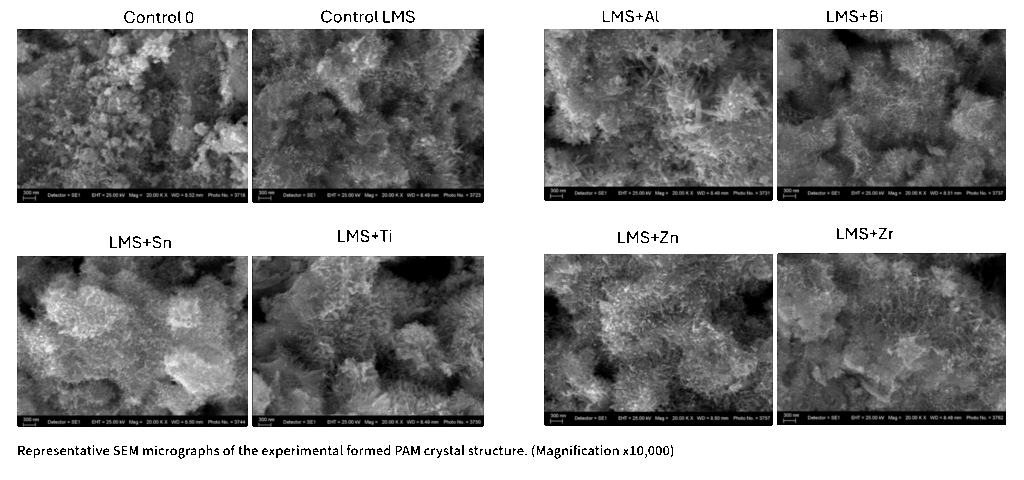

Promising additives are screened and characterised to determine their suitability, considering factors like chemical properties, impurities, cost, and manufacturing feasibility. Materials that pass this initial assessment undergo performance evaluations through experiments. These experiments analyse their impact on parameters such as paste density, curing time, and crystal growth, using small-scale 2-volt test cells.

We refine the formulation and dosage of these additives to optimise the final product. After that, we launch the experimental product for customer evaluations. This process from conception to commercialisation typically takes 2 to 5 years.

This project combines expertise from both industry and academia. How has collaboration with your partners influenced the research or shaped your approach so far?

To understand something in science, it's very useful to examine it using complementary techniques. The same applies to project teams with different backgrounds and experiences. This allows continuous review of the project from multiple perspectives.

Coming into this project, the concepts of how to evaluate auxiliary batteries and what is important to their performance were new to me. Collaborating with talented scientists from around the world has been immensely helpful. Meanwhile, working with team members has allowed us to access valuable resources and experience, and obtain high-quality data on our active materials and the electrochemical performance of additives.

What impact do you believe these findings could have on the broader competitiveness and sustainability of lead batteries?

Lead technology faces several well-known challenges to remain competitive and meet the evolving needs of energy storage markets. Moving forward, the goals are to increase battery cycle life and improve energy density. Achieving these targets will require innovations in active materials and battery design.

Exploring new additives and composite materials, such as lead silicates, can enhance properties like charge acceptance and extend cycle life. With every improvement, we can optimise lead batteries to meet specific needs and make them more competitive.

Finally, what excites you most about the direction of this research, both scientifically and in terms of its potential real-world impact?

The development of batteries for auxiliary BEV applications is still a relatively new field. There are many areas for learning and innovation.

We have the opportunity to study the "why" of what is happening within the battery active materials and to investigate the mechanisms behind the properties that affect charge recovery and pulse power performance. This understanding will allow us to modify the active materials or the battery system and achieve meaningful performance improvements.

Read more about the project here.

09/12/2025