Dual-chemistry projects are becoming increasingly common as demand for batteries is booming.

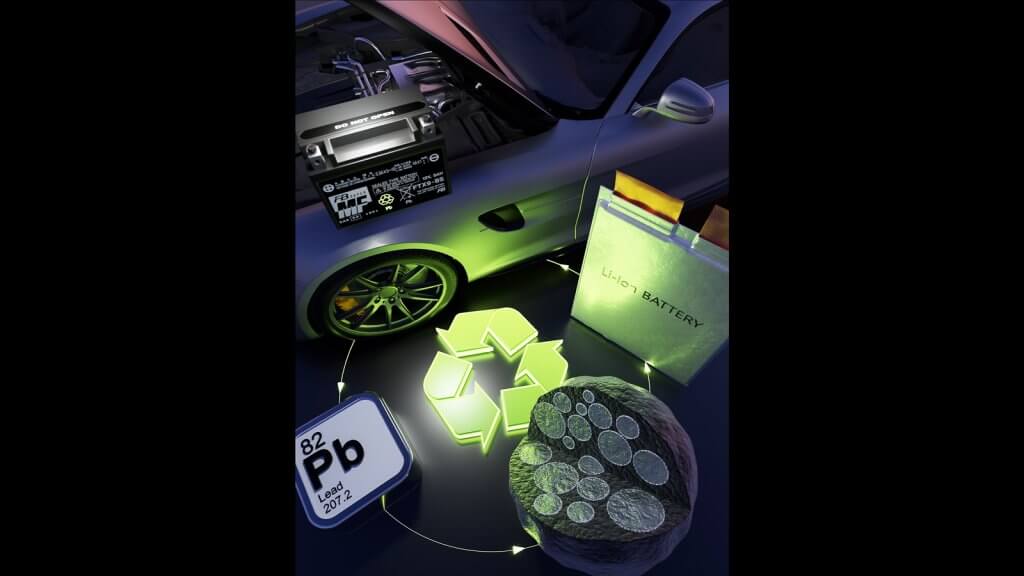

The world’s low-emission vehicle fleet is one of the prime examples of where different battery chemistries complement each other: virtually every electric vehicle has an auxiliary lead battery used for powering emergency functions if the primary lithium-ion battery fails.

We’re also witnessing the increasing use of dual-chemistry energy storage projects which combine the strengths different battery chemistry. From projects providing frequency regulation to stabilise electrical grids to electric vehicle charging projects, growing demand for battery energy storage means every chemistry has a significant role to play.

And now, in a pioneering research project underway at Argonne National Laboratory, the use of lead is being trialled for a new electrode design for the lithium-ion battery.

As a low-cost and plentiful metal, infinitely recyclable without losing beneficial properties, lead is offering exciting implications for designing low-cost, high-performance, sustainable lithium-ion batteries for the hybrid and all-electric vehicle market.

The research team have developed a simple, low-cost method for fabricating the lead anode used, which is made of lead nanoparticles embedded in a carbon matrix and enclosed by a think lead oxide shell.

Laboratory tests have already demonstrated the new lead-based anode can attain twice the energy storage capacity of current graphite anodes, with stable performance during cycling possible.

This exciting development to provide higher-performing lithium-ion traction batteries for low-emission vehicles by using lead would be underpinned by a successful home-grown lead battery value chain already based in the US.

The Consortium for Battery Innovation is driving forward innovation in advanced lead batteries to meet future technical demands for clean mobility and clean energy storage.

Read about the full research underway in a collaboration between Argonne, Northwestern University, Brookhaven National Laboratory and the Ulsan National Institute of Science and Technology (UNIST) here.

+++

'Getting the lead in' - Read Argonne's press release on the innovative project here.