The CBI 2024 Technical and ALBA Workshops were held from 11 to 13 June in Colombes, France. We welcomed over 90 technical experts from the lead battery and automotive industries around the globe, including some Asian battery manufacturers joining for the first time. After the workshops, the SSOF Working Group held their annual meeting in the same location.

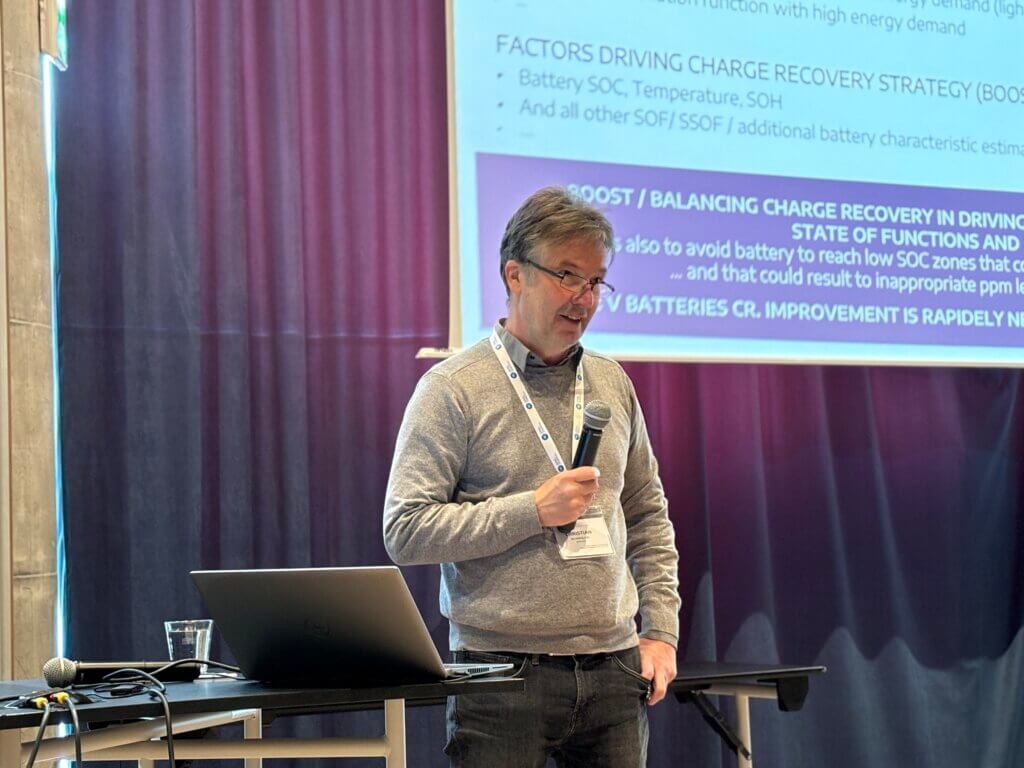

This year, the focus of ALBA was on auxiliary and backup applications. With the rapid advancements in automotive technology and the shift towards battery-electric vehicles (BEV), the requirements for the battery system are changing. ALBA convened various key players from the lead battery and automotive industries to discuss the advancements in 12V lead auxiliary battery research and strategies to promote this solution more widely to OEMs.

The main outcomes of the workshop were:

Read more about these highlights and see the photos of all events below.

The main workshop on Wednesday and Thursday intercalated plenary talks and interactive breakout sessions on a breadth of technical topics focusing on auxiliary and backup applications, particularly for BEV and in support of Functional Safety.

Attendees had ample opportunities to discuss topics such as best practices for cell design and testing, new approaches to optimise positive active mass (PAM) and positive plate durability, AGM cell saturation, new test methods and experimental data for charge recovery and test and sizing methods for auxiliary & backup batteries.

One key subject discussed was the development of the new IEC 60095-8 standard, which outlines updated requirements and test methods specific to lead batteries used for auxiliary and backup applications. The draft documentation is currently on the committee stage and will be circulated for comment and approval, being on track to reach the enquiry stage later in 2024.

One workshop highlight was the panel discussion with experts from Audi, Ford and Stellantis. This provided an excellent opportunity to receive direct feedback from OEMs about their requirements concerning lead batteries.

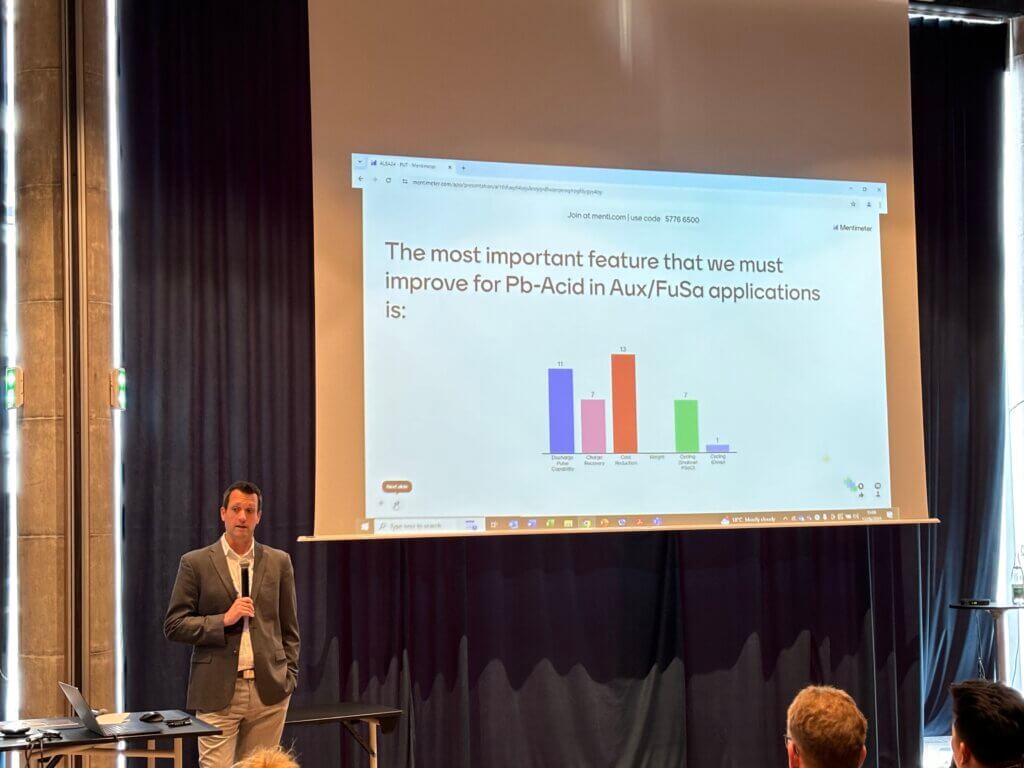

The experts recommended that battery manufacturers concentrate on reducing costs, improving charge recovery and reducing size to help maintain the competitiveness of 12V lead batteries in auxiliary and backup applications.

Safety is a top priority for OEMs. Initiatives such as the white book in development by the SSOF Working Group with data demonstrating 12V lead auxiliary batteries fulfil functional safety requirements were mentioned as the way forward to support lead battery manufacturers to propose their 12V solutions for BEV.

In addition to the technical discussions, for the first time at ALBA a session was dedicated to exploring market trends and opportunities for the lead battery supply base. Two ongoing market surveys, implemented with the support of CBI, are collecting feedback from 12V battery experts and 12V ASIL-BMS experts from OEMs globally. Preliminary results were discussed during this session.

Interactive surveys revealed that participants recognise the need to collaborate more closely with EV technologists. This collaboration must involve the collective development of better communication strategies with OEM decision-makers.

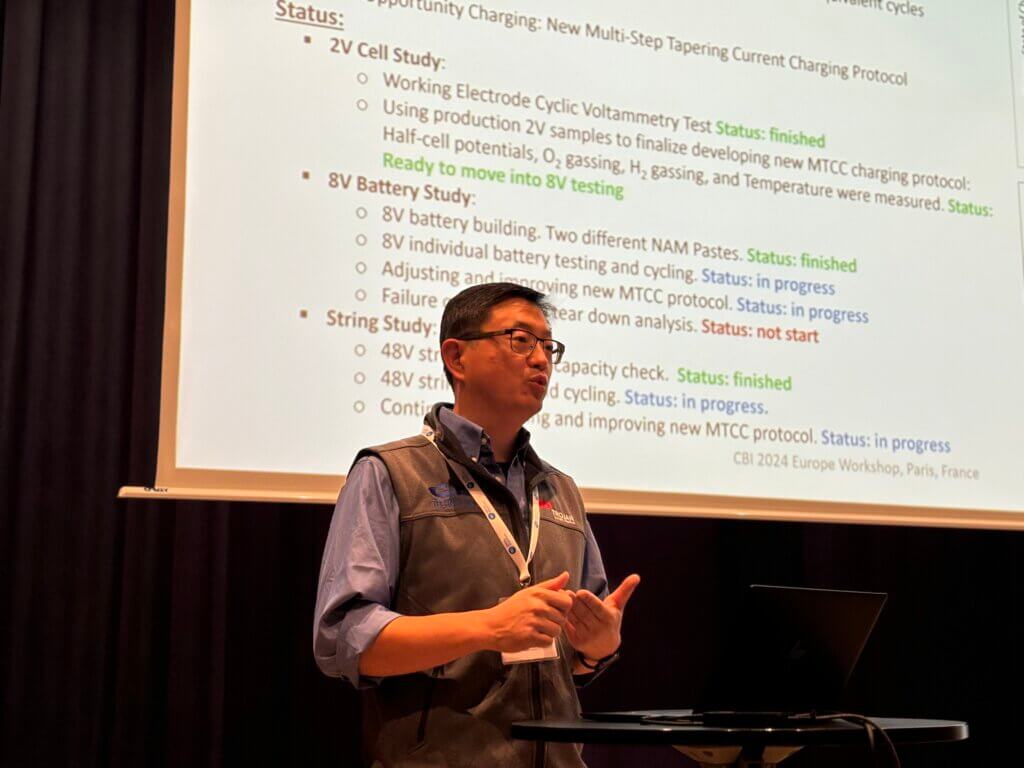

Just before ALBA, the CBI workshop on Tuesday highlighted projects funded by the Technical Program. Presentations included the final update on INMA and Exide’s project, which involved in-operando neutron scattering in industrial electrodes, as well as updates on two ongoing projects: C&D Trojan’s investigations of opportunity fast charging and UNT’s in-situ imaging and phase analysis of live cell materials during auxiliary battery cycling testing regimes.

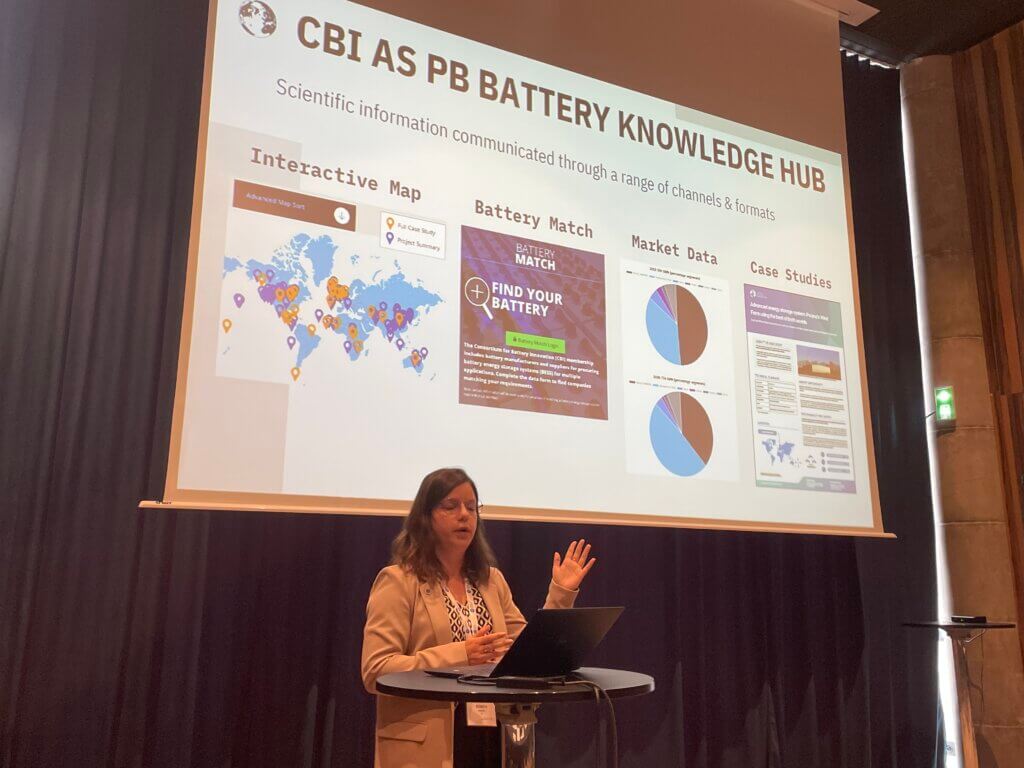

The CBI team also presented ongoing initiatives of the Research & Innovation Program in Europe and the USA demonstrating innovative energy storage applications, such as LoCEL-H2, Aftrak and the EV Charge Buffer Blueprint. The team concluded the workshop by discussing Communications & Marketing activities related to both programs.

23/09/2025